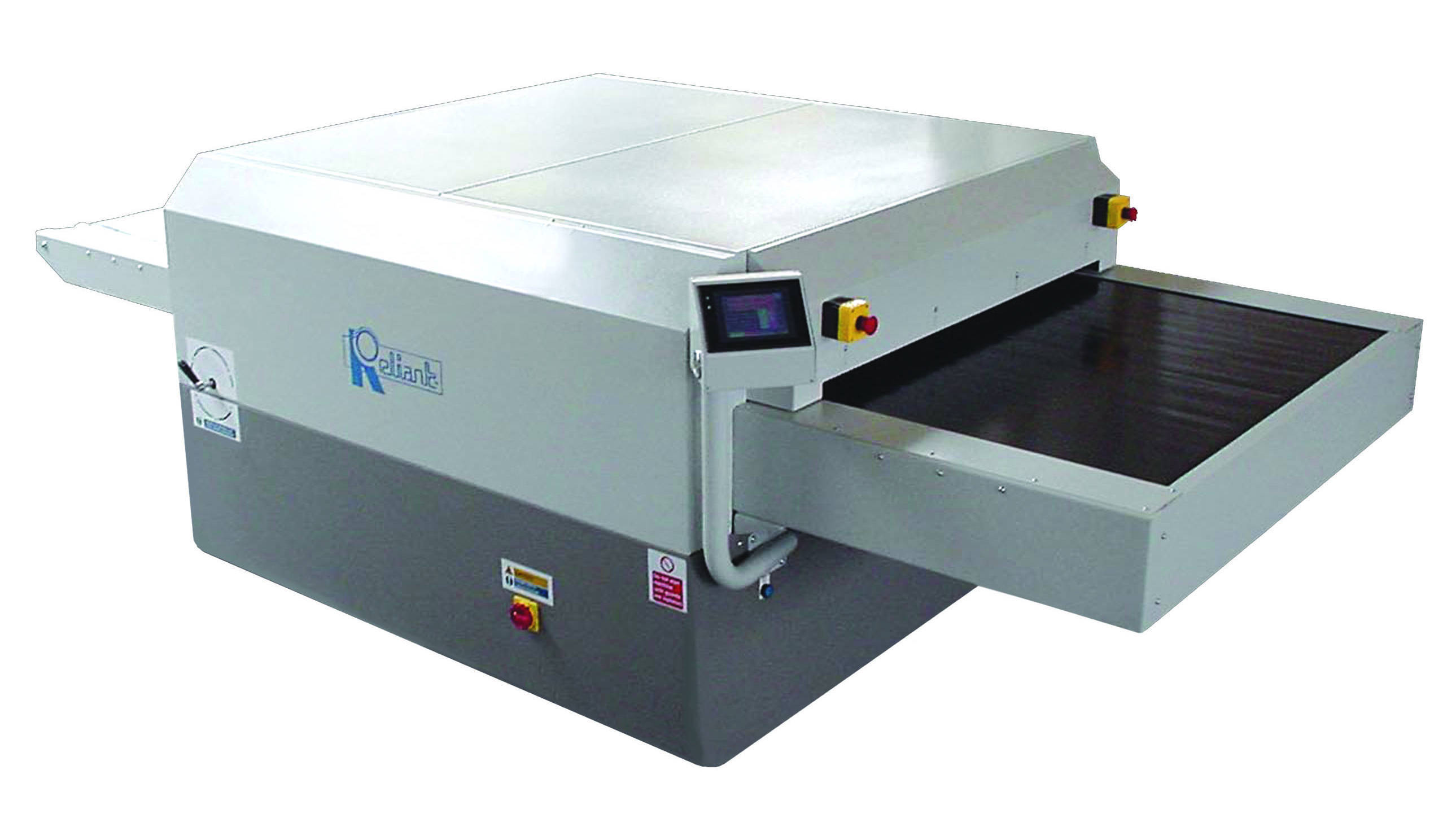

Fusing Machines

Description

Benefits of Reliant’s Fusing Machines

The elimination of fabric shrinkage, bubbling and other distortions, and heat shock effects on the fabric

The elimination of “Strike back” and “Strikethrough” of adhesive onto fabric surfaces and machinery

Flexibility of production including complete range of modern fabrics such as micro-fibers, viscose and viscose mixtures, lycra mixtures, etc. as well as the full range of interlinings

The elimination of expensive re-cuts and returned garments

Cost savings resulting from all of these technology benefits

Reliant offers, basically, four models of Fusing presses: Coolstream, Excel, Elite and Nova 45.

Coolstream High Production Fusing Press

The Coolstream is the state of the art fusing press for high volume production where quality control and finish is paramount. The Coolstream Fusing Press brings the best in fusing technology to the volume production factory.

The Coolstream fusing press is designed for the high quality production of all types of fused garment parts. It is especially effective for high quality outerwear fabrics where high volume throughput while maintaining the highest quality standards is required. It is for these reasons that some of the largest and best-known men’s suit manufacturers around the world use the Coolstream machine for their production.

Excel II Fusing Machine

The Excel II model brought 21st century PLC control technology to the well-tried and tested Reliant Excel range.

This machine offers superb quality fusing output for all types of fusing production from heavy weight outerwear, shirt collars and components right through to lightweight blouses, dresses and casual wear.

Elite M60 & M90 Fusing Machine

The Elite Fusing Machine Range brings the output quality of larger fusing equipment to a compact system.

The Elite offers great quality standards at a very affordable cost and space requirement and is suitable for all types of fusing output up to 90cm widths.

Nova 45 PN Fusing Machine

The Nova brings high pressure fusing to a small compact machine which can be used as a stand alone or in-line production system.

Noanother machine of this size and class offers fully adjustable pneumatic pressure which guarantees the output quality for all types of small parts, waistbands, etc.

- PLC programmable controls with built in job memory

- Low temperature fusing

- Horizontal flat run tunnel

- Elimination of shrinkage & fabric distortion

- Power consumption – heat saving

- Tri zone heating and control via PLC

- PID temperature control via PLC

- Auto compensating “floater heater” modules

- Conveyor Belt Sensing Zone (BSZ)

- Synchro-Trak belt tracking

- High pressure capability

- Effective fabric cooling

- Automatic four stage cleaning

- Controls and self diagnostics via PLC

- Pneumatic high pressure capability for high quality output

- Guaranteed even pressure for consistent quality production

- Heating layout ensures even temperatures

- Accurate temperature control for better quality output

- Straight through tunnel layout ensures no distortions

- Ergonomic design for efficient production

- Easy maintenance system ensures high reliability

- Wide width fusing capabilities for all fabric sizes

- Flexible production system

- Easy to view controls

Address

Reliant Machinery Ltd.

Unit L Cradock Road

Luton

LU4 0JF

Grossbritannien und Nordirland

Telephone+44 1582 584999

Fax+44 1582 581117

Discover more from us