Laminating Machines

Description

The Powerbond range is divided in HPC, HPL and SPL models; it is Reliant’s flagship laminator range, incorporating the unique, well-tried and tested modular construction.

The Powerbond range is used in many different industries for materials starting with films of a few microns thick, through to products of up to 150mm thick.The design allows machines to be assembled to fit exactly to the customer’s production specifications.

The Powerbond-HPC brings Reliant’s fully modular assembly together with a high-pressure system capable of applying significantly increased levels of pressure during heating and cooling.

The Powerbond HPL, due to Its robust design is ideal for products requiring significant pressure and contact during the lamination. But don’t need to be fully compacted during the process.

The design of our Powerbond SPL starts with a 1700mm heating section, additional 1000mm sections of heating, cooling and pressure systems, can be assembled together to provide a machine of any capacity required.

The Coolstream TAL provides high volume laminating capacity with the flexibility to bond thicker products, using its height adjustbale lamination tunnel. Products up to 50mm thick can be laminated on this machine making it highly adaptable and suitable for processing a wide range of materials including foams, composites, nonwovens, breathable membranes, textiles and others.

The Coolstream MPG range provides a medium to the high capacity laminating system at an affordable cost. The unique Reliant GOS (Gap Opening System) allows both thin and resilient materials to be processed through the machine without adding significant cost to the equipment.

The Magnum GOS range brings reliable, high quality, performance equipment, into a lower dimension of investment for smaller and medium processing volume requirements. The Magnum incorporates features normally only available on larger and costly machines. These include the ability to laminate multy-layer laminates in one pass, feeding of sheets, reel-to-reel or sheet-reel-sheet formats.

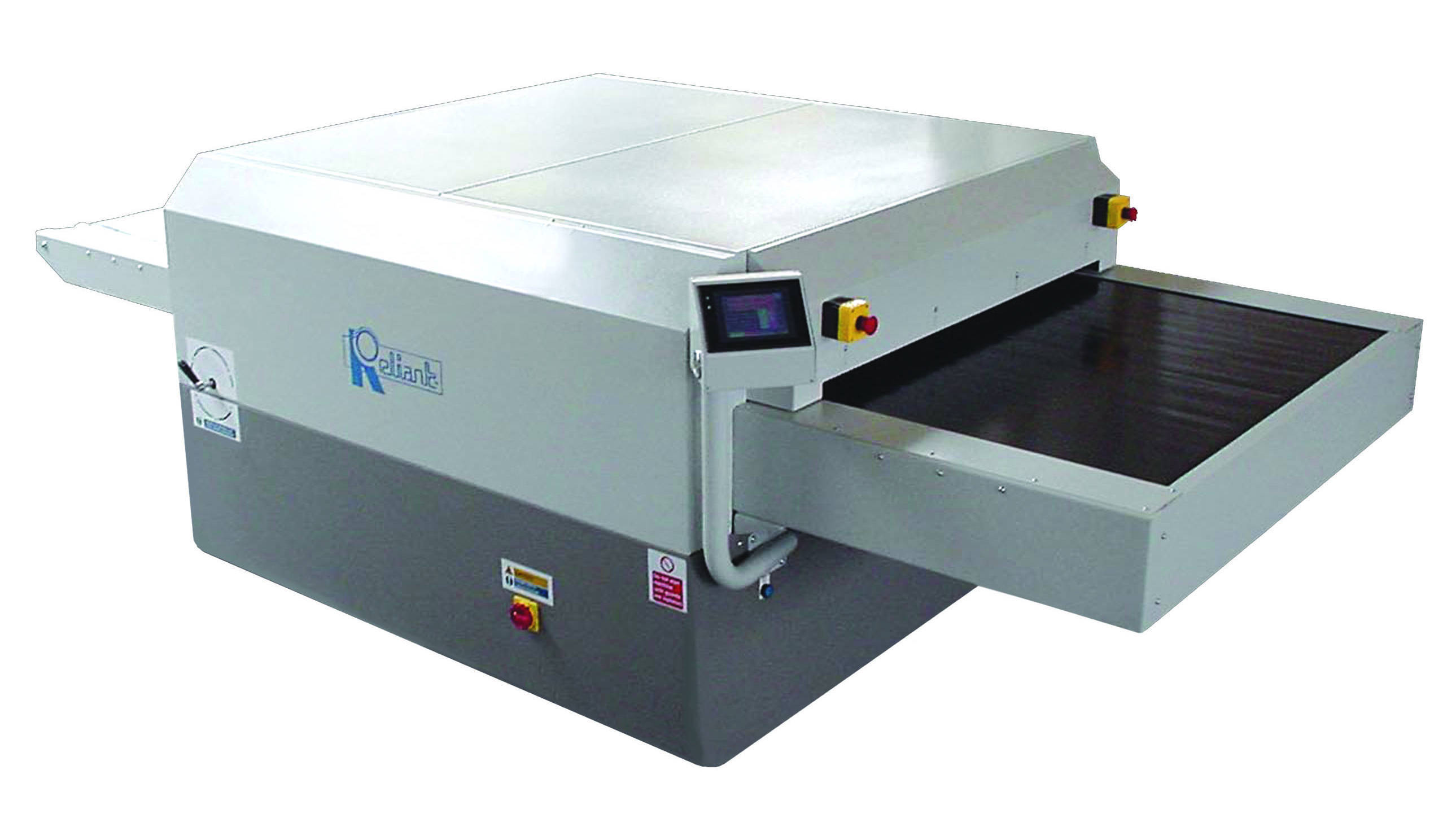

The Compact HCL is a cost-effective way to create laminates with both heating and cooling sections. The Compact HCL combines many functions and advantages of Reliant’s larger equipment, like zoned PID controlled heating and pneumatic pressure on a much smaller scale. Using the mechanical adjustment, the tunnel will allow thicker materials to be processed by manually setting the gap between the belts to a maximum of 25mm.

Address

Reliant Machinery Ltd.

Unit L Cradock Road

Luton

LU4 0JF

Great Britain and Northern Ireland

Telephone+44 1582 584999

Fax+44 1582 581117

Discover more from us