Lines for stabilization, carbonization & activation

Description

Lines for stabilization, carbonization & activation of precursor material for carbon fiber yarn

Stabilization is an important process step in the creation of high-quality carbon fibers. For this process DIENES offers furnace systems with high temperature accuracy. The optimized system for yarn transportation with DIENES own godets implements a tension-controlled stabilization.

Subsequently to the stabilization the carbonization of the material follows, which is usually performed in a two-stage process in an inert atmosphere and at temperatures of up to 2.800 °C. DIENES offers thread guiding equipment and together with its partners carbonization ovens.

DIENES also offers modules for the activation process of the carbon fiber which includes treatments such as electrolytic surface treatment and sizing application.

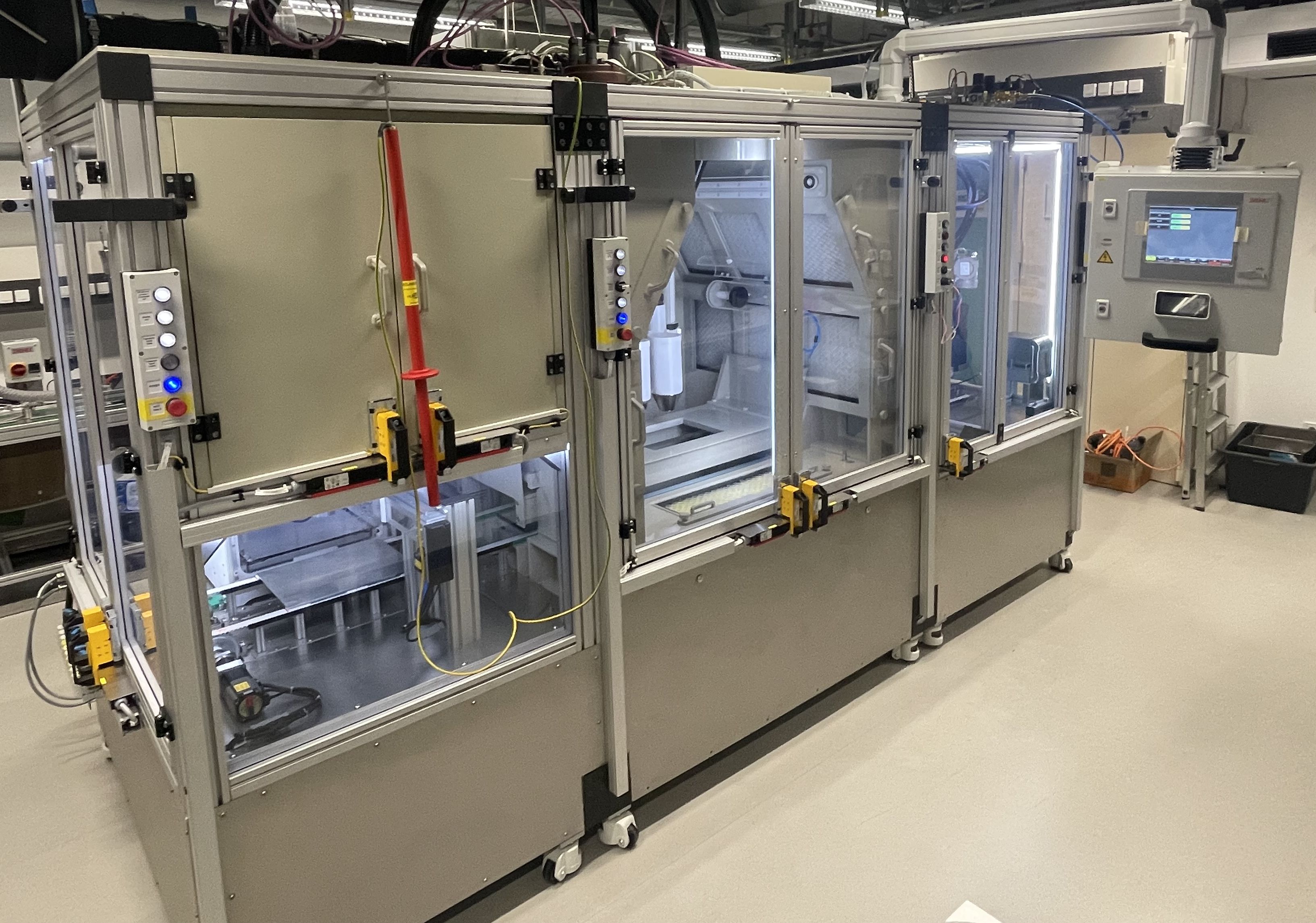

In a MultiMode® plant, each process step is represented by a module which can be individually adapted to customer-specific requirements and has its own decentralized control. Thus, DIENES production lines consist of several intelligent modular units which can be easily exchanged and rearranged at any time with a reduced programming effort. Moreover, all production parameters can be permanently visualized and recorded, enabling a complete traceability of the process.

MultiMode® - Research 4.0

The development of new innovative filaments demands an efficient systematic and, in part, self-optimising experimental working system, which must be intelligent in gathering data from the process and flexible in enabling the rearrangement of the process.

Our implementation of the Research 4.0 approach is called MultiMode® and ensures high flexibility, modularity and versatile applicability. Each module can be individually adapted to customer-specific requirements and has its own decentralised control, which is the key for its integration into any plant at any time with a reduced programming effort.

In connection with the DIENES visualization unit all process-relevant data is graphically available for the user. Changes in the process can be made effectively by entering data via touchscreen. Through the combination of several DIENES MultiMode® modules and the integration of a MultiMode® Master (MMM), all local controls are displayed in a central control panel.

For the analysis of complex relationships to carry out process analysis the MMM is getting extended by a DIENES MultiMode® Explorer (MME). In the MME developed by Dienes, all process data are permanently visualised and recorded with a high degree of transparency for further evaluation. From system expansions to process development the MultiMode offers a customized process control system for your application.

Control set-up available with:

- Local and central visualization per unit

- Central visualization for line

- Process evaluation in real time

- Data logging for all parameters

- Access control via user administration incl. password

Address

Dienes Apparatebau GmbH

Philipp-Reis-Str. 16

63165 Mühlheim am Main

Germany

Telephone+49 6108 707111

Fax+49 6108 707100

Discover more from us