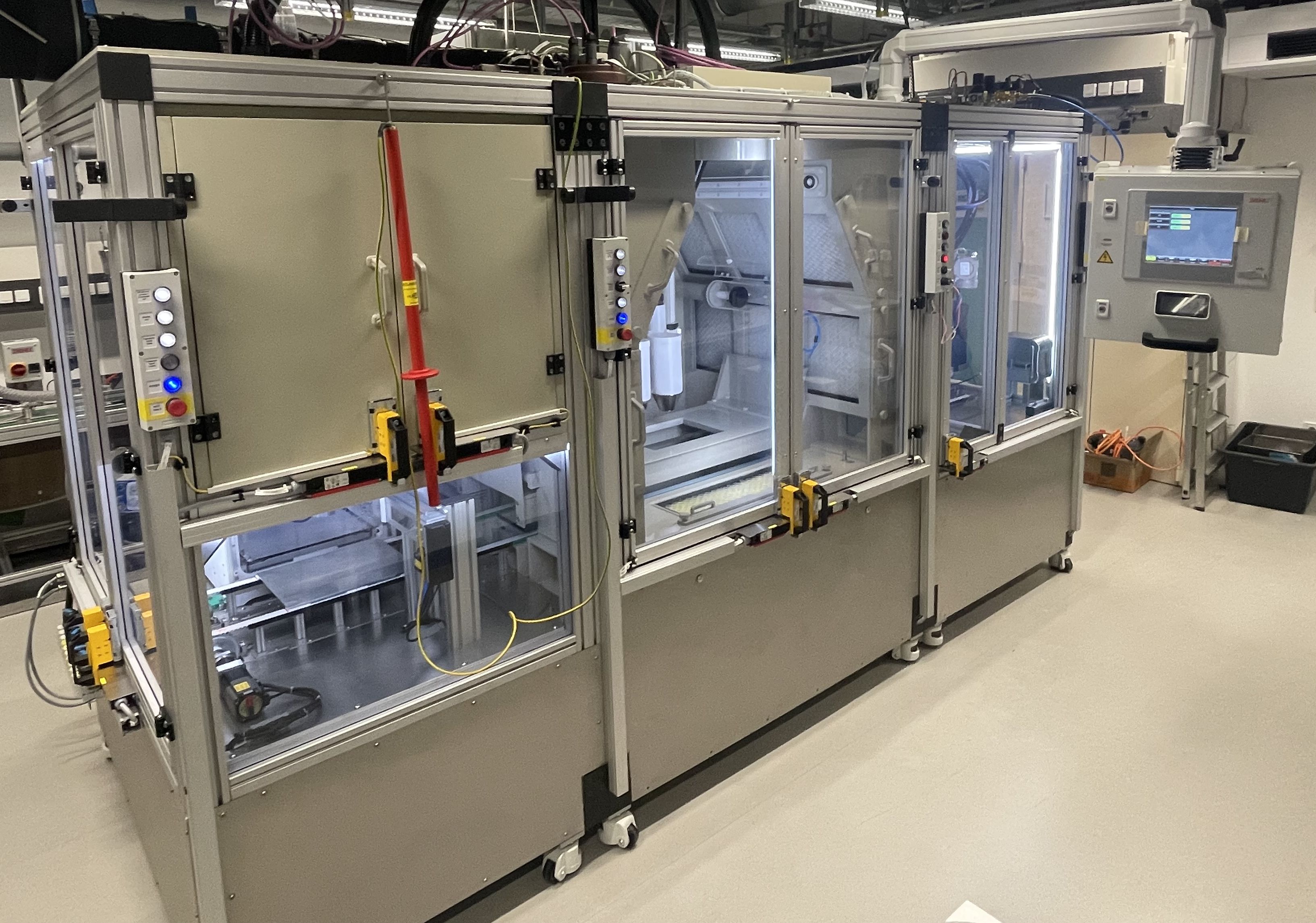

Wet Spinning Line

Description

The DIENES wet spinning lines in standard or air-gap execution enable highest performance in the production process. The wet spinning lines consist of various main steps: coagulation - washing – drawing – drying – fixation – winding.

In a MultiMode® plant, each process step is represented by a module which can be individually adapted to customer-specific requirements and has its own decentralized control. Thus, DIENES production lines consist of several intelligent modular units which can be easily exchanged and rearranged at any time with a reduced programming effort. Moreover, all production parameters can be permanently visualized and recorded, enabling a complete traceability of the process.

The general set-up and the complexity of the machine depend on the process and the customer's target.

We offer:

- Lab lines with independently driven modules

- Pilot plants: modules are connected in the MultiMode® principle

- Production lines

Filament Fibers made from:

- Polyester (PET)

- Polypropylen (PP)

- Polyamide (PA6.6, PA6)

- Polyacryl (PAN)

- Textile and Technical Viscose

- New Cellulose NMMO

- SiO2, Al2O3

- Amorphous Materials

- Composite Materials

Equipment for the production and treatment of:

- Multifilaments low speed spinning (e.g. precursor)

- Monofilaments (e.g. medical and reinforcement)

- Nanofibers (webs)

MultiMode® - Research 4.0

The development of new innovative filaments demands an efficient systematic and, in part, self-optimising experimental working system, which must be intelligent in gathering data from the process and flexible in enabling the rearrangement of the process.

Our implementation of the Research 4.0 approach is called MultiMode® and ensures high flexibility, modularity and versatile applicability. Each module can be individually adapted to customer-specific requirements and has its own decentralised control, which is the key for its integration into any plant at any time with a reduced programming effort.

In connection with the DIENES visualization unit all process-relevant data is graphically available for the user. Changes in the process can be made effectively by entering data via touchscreen. Through the combination of several DIENES MultiMode® modules and the integration of a MultiMode® Master (MMM), all local controls are displayed in a central control panel.

For the analysis of complex relationships to carry out process analysis the MMM is getting extended by a DIENES MultiMode® Explorer (MME). In the MME developed by Dienes, all process data are permanently visualised and recorded with a high degree of transparency for further evaluation. From system expansions to process development the MultiMode offers a customized process control system for your application.

Control set-up available with:

- Local and central visualization per unit

- Central visualization for line

- Process evaluation in real time

- Data logging for all parameters

- Access control via user administration incl. password