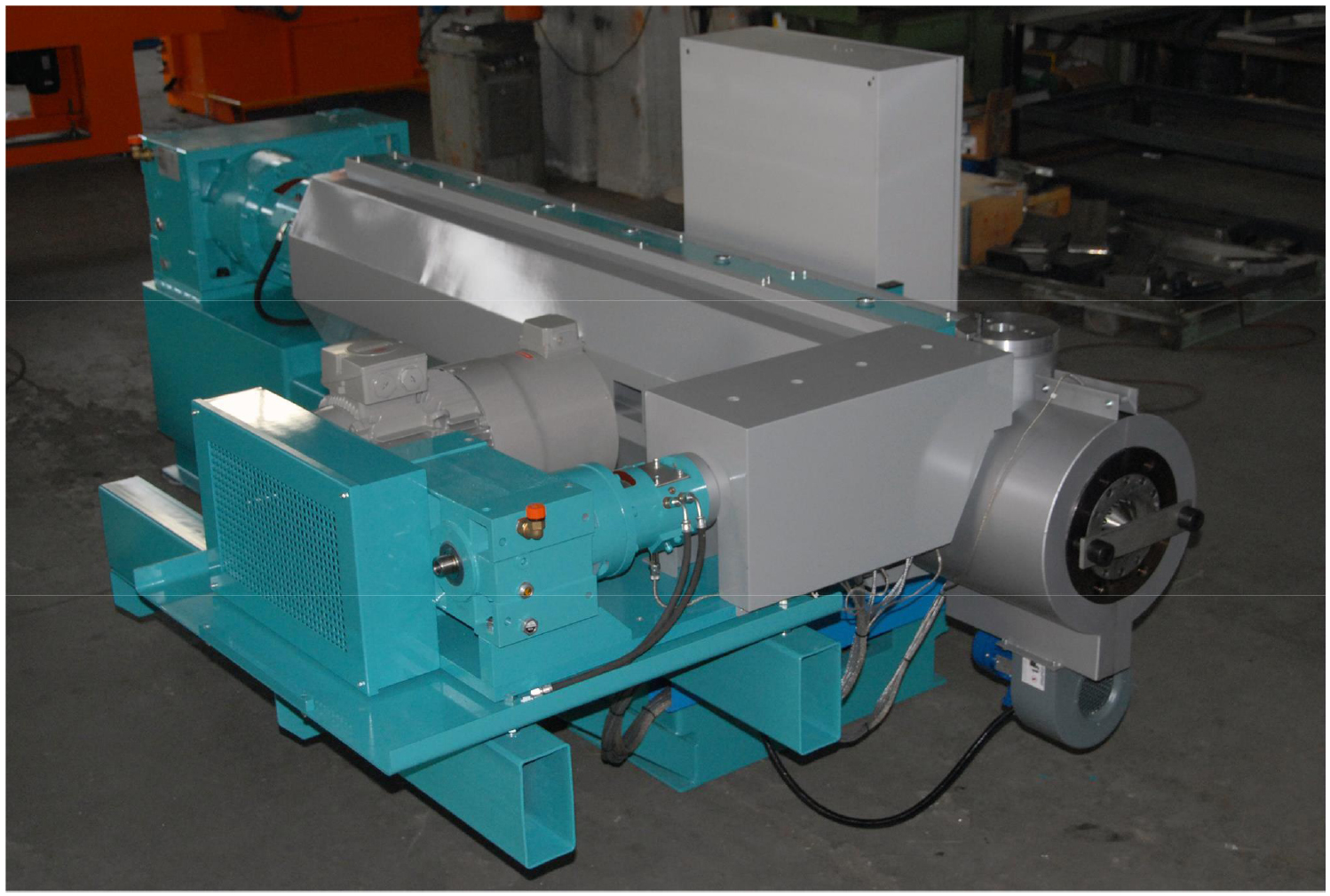

VB - MONO spinning systems for monofilament production

Description

VB-MONO concept is an extrusion line designed to produce high quality monofilament yarns processing standard polymers like PET, PA6, PA66, PBT, PP, PE.

The line can be designed with technological upgrade in order to process high performance polymers like PA12, PLA, PPS, etc.

Each line is designed for an optimum diameter range depending from number of monofilament and required throughput

Highlights:

- Produce diameter ranges from 0,07 to 2,00 mm.

- Process standard polymers and high performance polymers

- Available design for production of bicomponent monofilament

- Draw of the monofilament in hot air oven, steam or water bath

- Annealing of the monofilament in hot air ovens

- Low energy cost

- Easy maintenance

High quality monofilament

All components are designed to keep high precision on temperature uniformity in extrusion, polymer distribution, spinneret heating, filament cooling, godets, stretching and annealing ovens. The result is a uniform product with low CV of the main product parameters.

Spinning performance

Polymer melt distribution in the spin pack/spinneret and the choice of mixing points of the melt stream allows narrow deviation of the filament size and even monofilament section.

Low residence time respecting the ideal melt polymer share rate allow minimum degradation of the polymer, to reach yarn tenacity level up to 7 gpd.

Stretching and annealing

Air ovens are designed to keep temperature variation within 1 degree from set point. The airflow is laminar, and the monofilaments inside the oven maintain straight path with minimum vibration

Different machine set-up for all kind of monofilament yarn

Monofilament machine can be supplied with one extruder or with two extruders for bi-colour of bicomponent yarn production.

Address

VB-SET S.r.l.

Via Tevere 1

20020 Vanzaghello Milano

Italy

Telephone+39 0331 307143

Fax+39 0331 307999

Discover more from us