The exhibitors & products at Techtextil 2026 will be available here from mid-January 2026.

RA VISION - AUTOMATED INSTRUMENT MULTIPLE-HEAD, FIRST VISUAL OPTICAL CONTROL OF POY, FOY, FDY AND DTY SPINNING YARNS AND TEXTURED BOBBINS QUALITY INSPECTION

RA VISION - AUTOMATED INSTRUMENT MULTIPLE-HEAD, FIRST VISUAL OPTICAL CONTROL OF POY, FOY, FDY AND DTY SPINNING YARNS AND TEXTURED BOBBINS QUALITY INSPECTION

Description

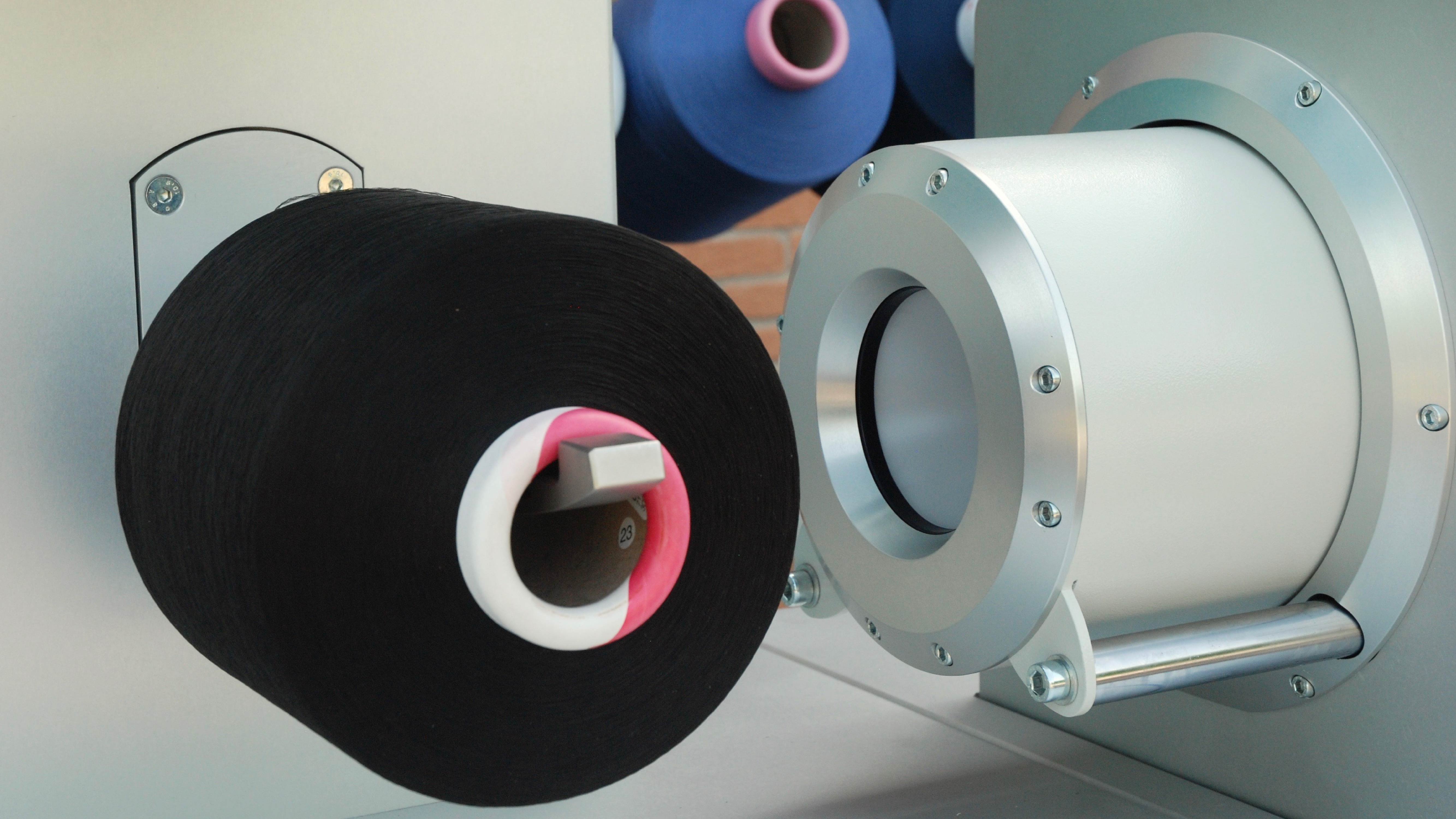

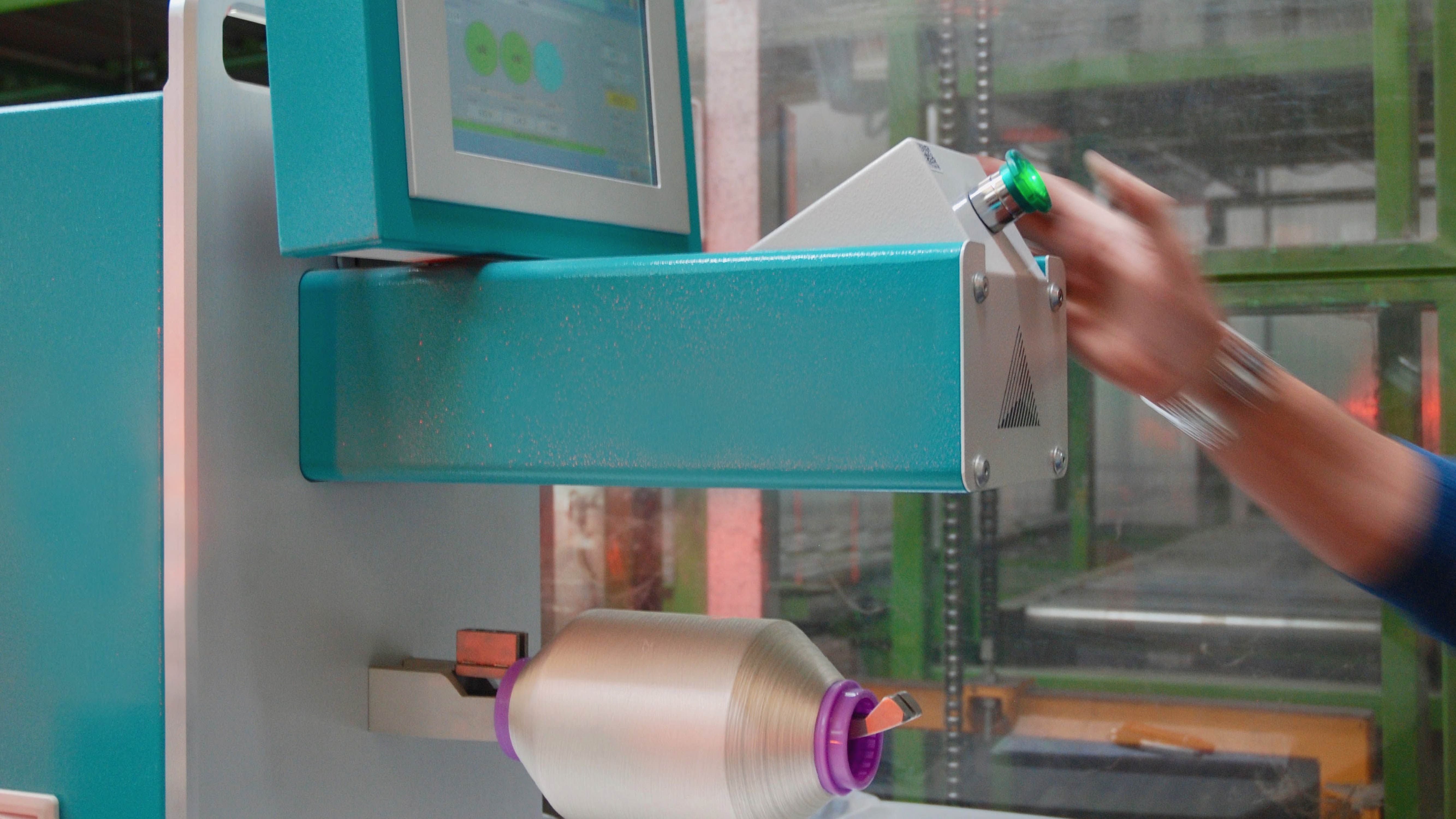

RA VISION is a Thema 2 patented instrument/machine for the automated control of bobbins of POY, FDY, FOY, and DTY, capable of verifying even up to 32 yarn bobbins simultaneously in a few seconds.

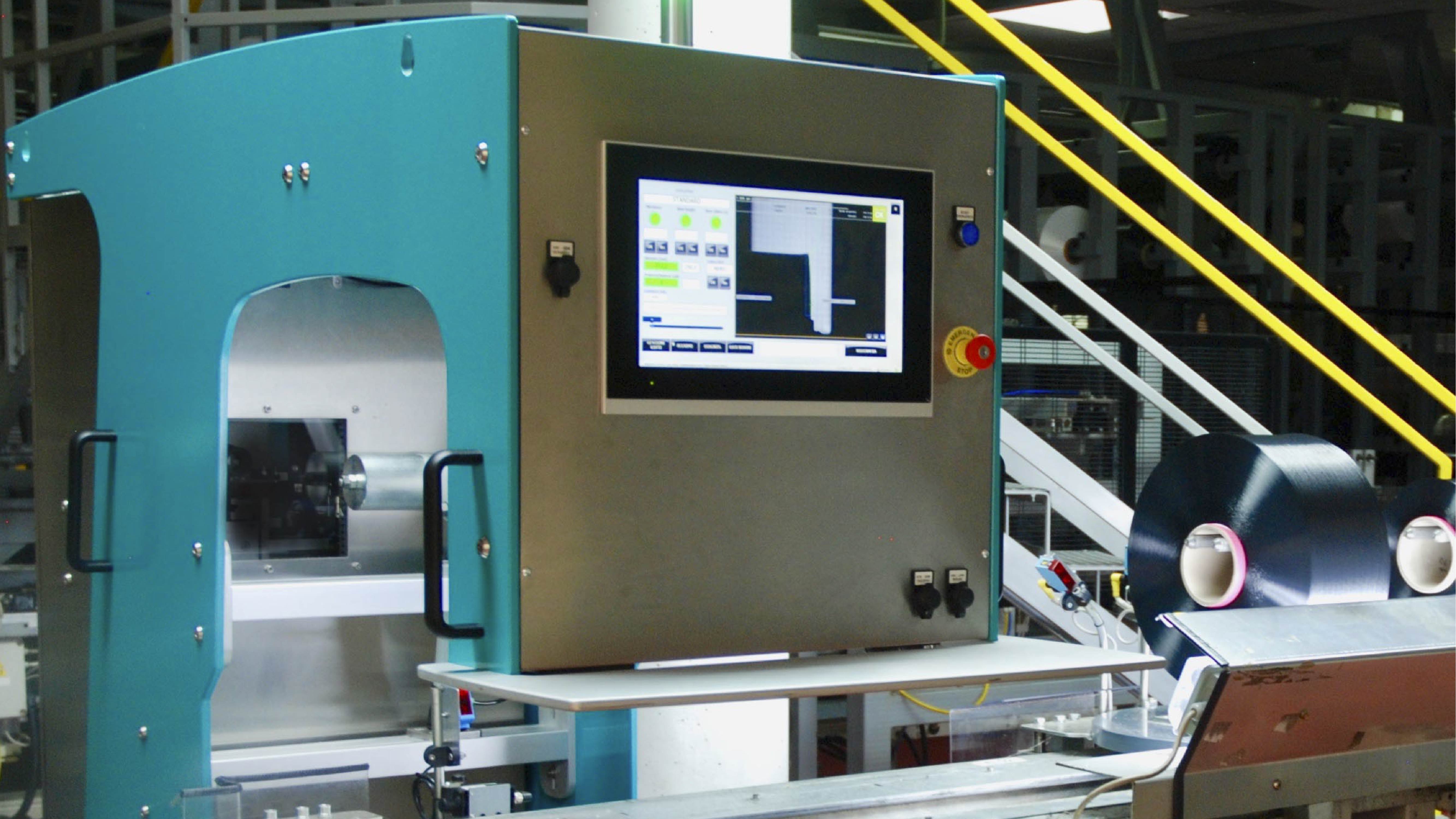

The interface with the PLC for automation management can take place through the computer network or with the assistance of simple digital exchanges. The instrument conducts the whole series of checks, automatically classifying the bobbins by quality based on the percentage and type of defects collected and verified.

All the detected parameters, in addition to being stored on the instrument PC, can be transmitted by a computer network (wireless or Ethernet cable) to the Company Management system and shared on a common DB for complete traceability of the quality control performed and consequent correct production management.

The multi-head Ra Vision can be installed on existing or new handling plants or as a completely independent quality control system. Thema 2 textile laboratory is at the Customer's complete disposal to conduct a series of checks on yarn bobbins and to draw up a detailed booklet report of the complete processes and events encountered. The same will be accompanied by a series of images that will show the events detected by the neural intelligence of our Ra Vision instrument.