The exhibitors & products at Techtextil 2026 will be available here from mid-January 2026.

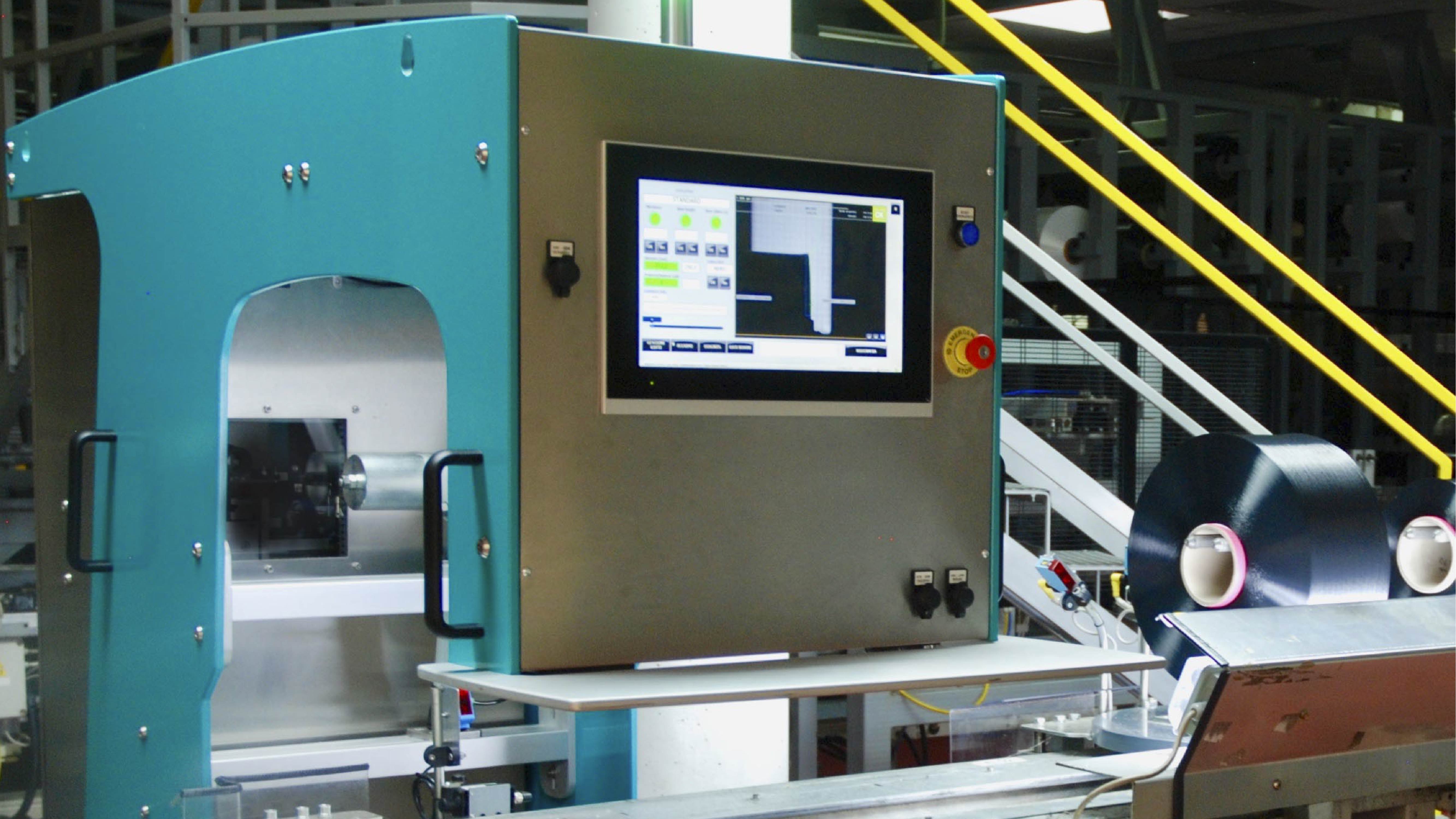

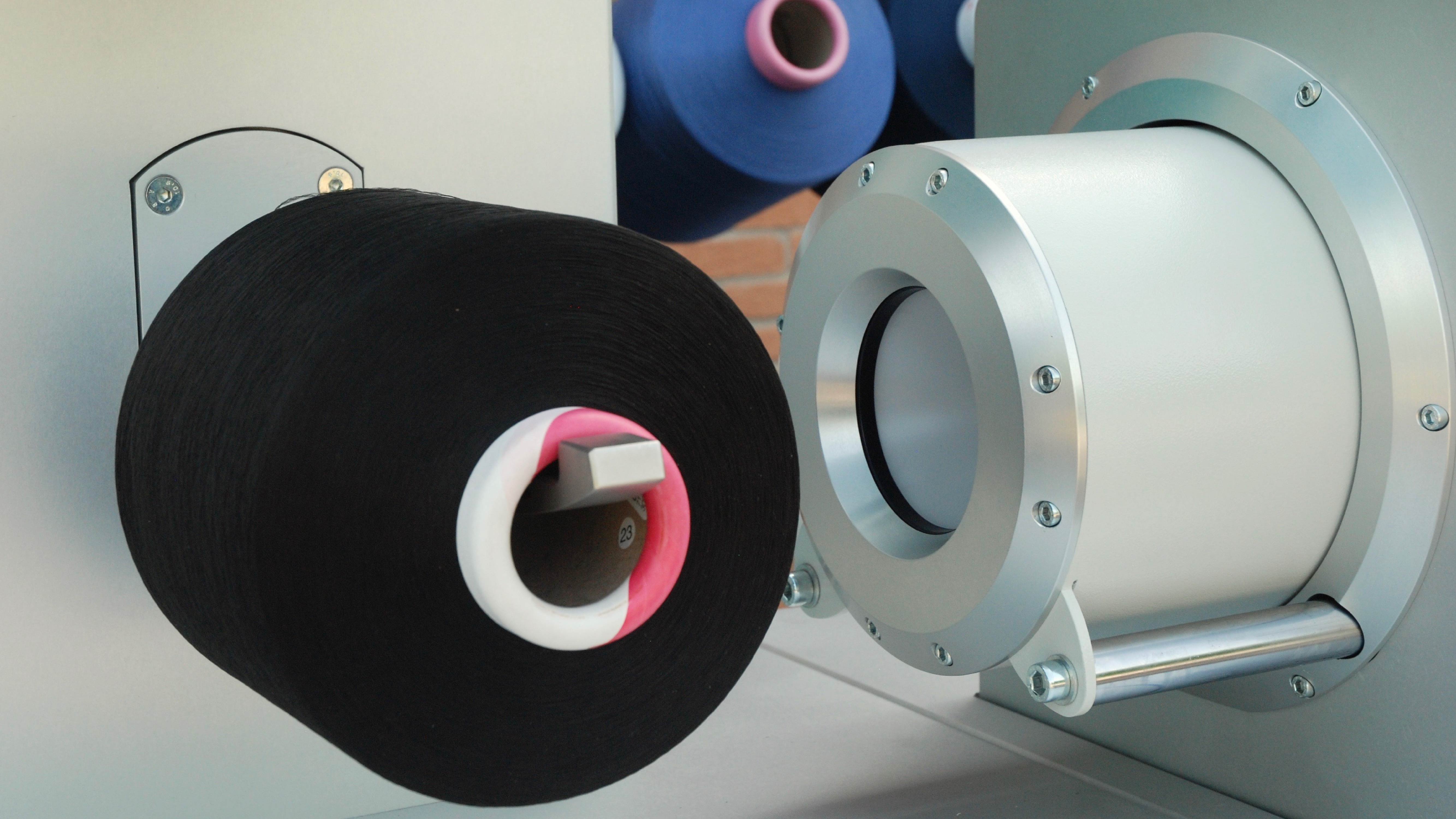

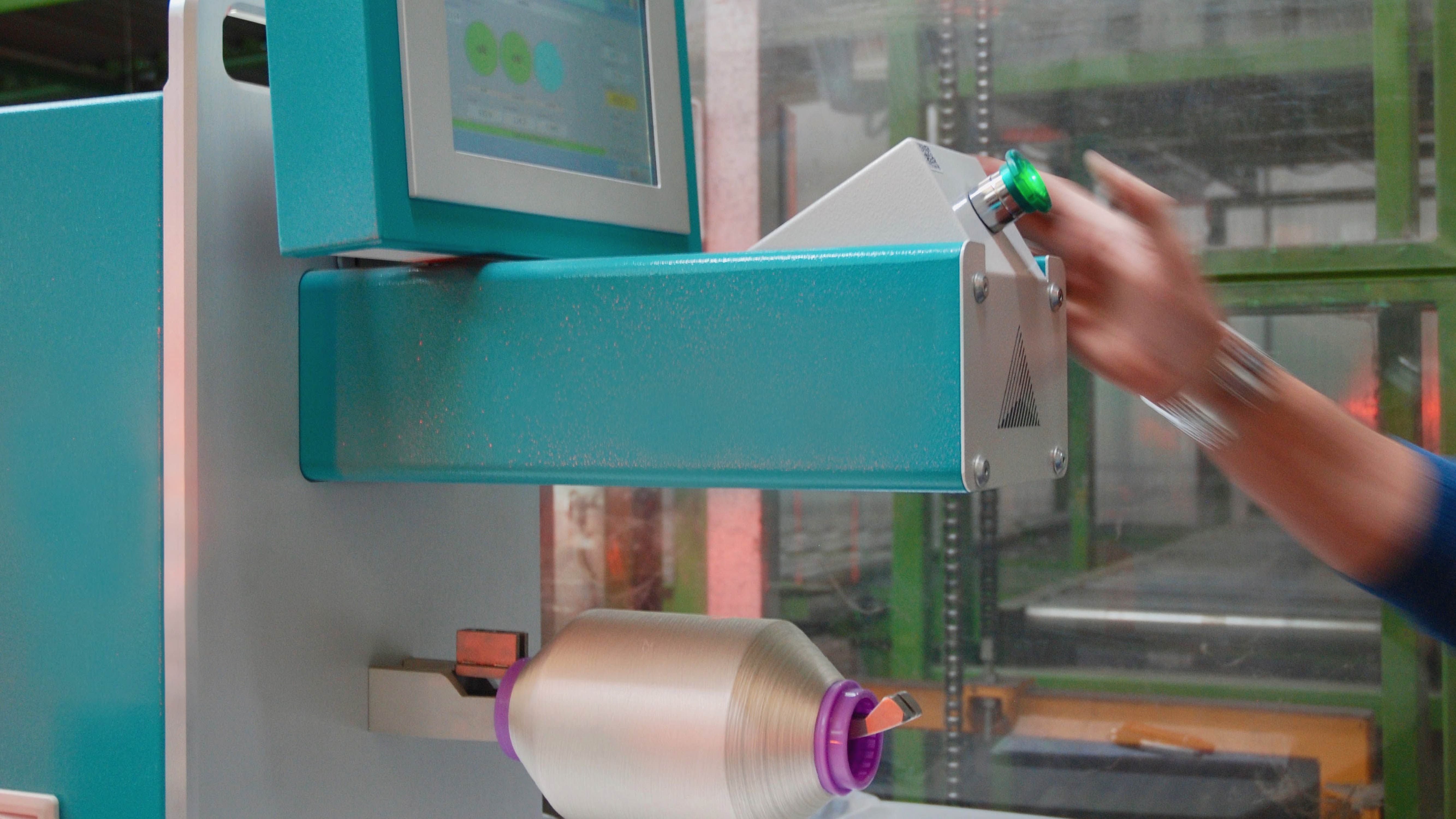

TAC80 - MULTI-HEADS PRECISE METER COUNTERS

TAC80 - MULTI-HEADS PRECISE METER COUNTERS

Description

TAC80 is a device with a meter counter on every single position on multi-head textile machines, suitable to be utilized on cops winders, bobbin winders for flanged bobbins for elastane covering process, re-winders for every kind of cones or bobbins and on texturing machines too. With the use of the TAC80 meter counters, a perfect result will be achieved in the yarn preparation before the twisting operation and in the covering process too, where the preparation of meter length windings perfectly equal among each single position is necessary. In the warp process, the yarn perfect length of the bobbins or cones utilized on the creel is considered as a standard. The precision in the measurement of the wound meters determines a series of advantages for increasing the production efficiency, for the reduction of energy consumption, for the better efficiency and optimization of the machine’s operations, and the drastic reduction of the yarn waste.