Flame laminating machine/Flame bonding machine

Description

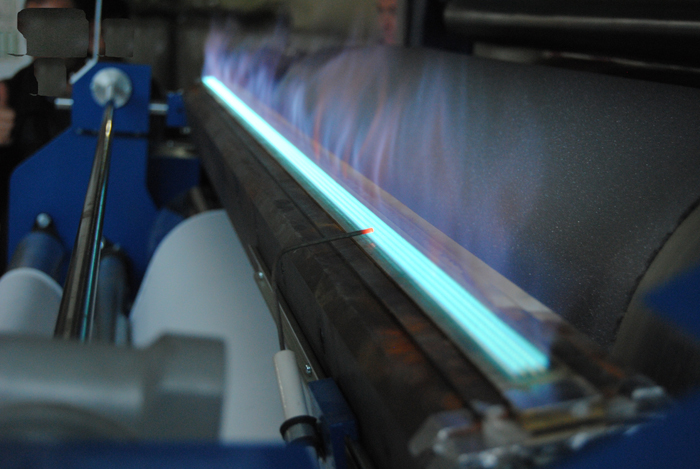

Flame laminating machine allows the coupling of polyester or flammable polyether foams to different substrates such as woven fabrics, knitted fabrics, non-wovens synthetic leather, films, since it allows to bond the substrates on both sides of the foam in one run and obtain three laminate materials.

Rebec can supply both flame lamination non-stop lines, with large production capacity and flame lamination lines with small and medium production capacity. Flame bonding machines can be simple, with manual adjustments or automatic adjustments of the working parameters by servo controls, PLC and PC.

Our burners are made of cast iron made from solid bars. Cast iron burners have a longer life than aluminum burners especially if you process corrosive foams (some flame-retardant foams used for the automotive industry).

In addition, the perforated ribbon to shape the flame slides on one side and therefore it can be easily and quickly removed for cleaning.

Discover more from us