Rebec srl

Discover more from us

About us

Rebec srl has developed a multi-year experience in the coating and laminating of textiles, plastic films and paper, developing solutions for small and big companies.

Rebec srl designs and builds machines for lamination, coating and perforation.

Products:

- flame lamination machines

- hot melt machines

- coating machines

- powder spreading machines

- perforators for leather, foams and fabrics

- accessories: unwinders, winders, accumulators, calenders, ovens, edge trimming units, welding machines, etc.

We make changes to existing installations, revisions, upgrades, technical analysis and advice, starting with a collaboration with the client, from conception to implementation, to reach the best results.

We cooperate with a solid network of big Italian companies. This allows us to call on the assistance of external advisory groups, key specialists in the area.

Our product groups

- Technology and Processes

- Bondtec (Surface & Bonding Techniques)

Our application areas / Solutions

Downloads

Keywords

- Laminating machines

- Coating machines

- Powder scattering machines

- Hot melt machines

- Flame laminating machines

Our Products

Hot melt machine

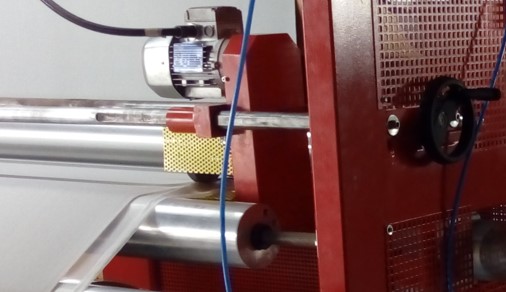

Rebec hot melt machine is modular and can be equipped both with the gravure roller application system, to coat the hotmelt adhesive in points or network shape and with the multiroller application system, to fully cover the substrate with hotmelt adhesive. The modules are interchangeable one with the other. The machine can also be supplied equipped with only one coating system.

Rebec machine is extremely versatile and all plants are equipped with low or high tension web transport drives and tensions are controlled electronically with load cells and dancer rollers. Control system can be regulated thanks to a software easy and effective. Several web guiding systems ensure a proper alignment of the web layers for coating ad lamination. Accumulators (J-box, roll and belt) ensure an on-going process with no stop during batch changes.

Our machine is studied to facilitate the operators job, it is extremely user-friendly. We developed a configuration that allows to change rollers and components very quickly and to do the cleaning very easily.

With the use of coating technology and coupling with hotmelt adhesives, the recyclability of finished products is also facilitated, following the direction indicated by the community regulations.

Coating machine

Rebec supplies coating machines for the production of self-adhesive materials, resin-based fabrics, waterproofing and blackout.

Some features of Rebec knife coating machine: coating accuracy assured by the machine solidity, by very good tension control on the material, precision in working the knife and the roller.

Dimensions and production capacity of the lines are according to customers’ specific needs.

It is also possible to supply combined systems, with coating and more screen to spread on drawing or with dots. It is possible to apply polyurethane, acrylic, silicone, latex and PVC pastes.

The drying ovens can be heated with gas burners or diathermic oil.

Powder scattering machine

Our powder coating machine spreads thermo adhesive powder of various nature and granulometry, it is a very solid machine, which in addition to ensuring great precision of spreading, is equipped with an automatic system, which ensures the same amount of powder selected as the production speed.

The products obtained with adhesive powder scattering and lamination are used in various sectors such as automotive, footwear, clothing and furnishing.

The type of powder is chosen according to the materials to be heat-adhesive or to match fabrics, TNT, film, wadding, artificial leather etc.

Rebec can supply both single machines, such as spreaders, infrared ovens, calenders, and special systems designed to meet specific customer needs, up to 5300 mm width. It is possible to start from a basic plant and then extend it step by step in the future, with the addition of accumulators, edge trimming systems, etc.

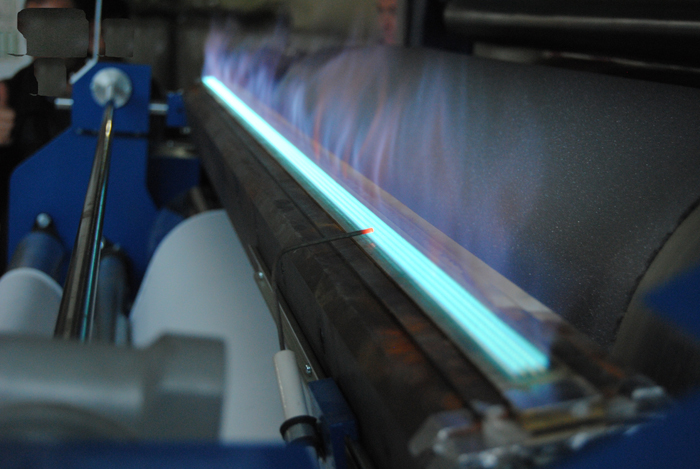

Flame laminating machine/Flame bonding machine

Flame laminating machine allows the coupling of polyester or flammable polyether foams to different substrates such as woven fabrics, knitted fabrics, non-wovens synthetic leather, films, since it allows to bond the substrates on both sides of the foam in one run and obtain three laminate materials.

Rebec can supply both flame lamination non-stop lines, with large production capacity and flame lamination lines with small and medium production capacity. Flame bonding machines can be simple, with manual adjustments or automatic adjustments of the working parameters by servo controls, PLC and PC.

Our burners are made of cast iron made from solid bars. Cast iron burners have a longer life than aluminum burners especially if you process corrosive foams (some flame-retardant foams used for the automotive industry).

In addition, the perforated ribbon to shape the flame slides on one side and therefore it can be easily and quickly removed for cleaning.

Edges trimming cutting unit

Provided with two cutting heads, is designed to cut (trim) the edges of both the simple layer materials and the bonded ones.

It can be equipped with a vacuum system suitable for removing the trimmed-off strips of material, from the cutting units to the gathering container.