Thermoset Powder Coating

Thermoset Powder Coating

Description

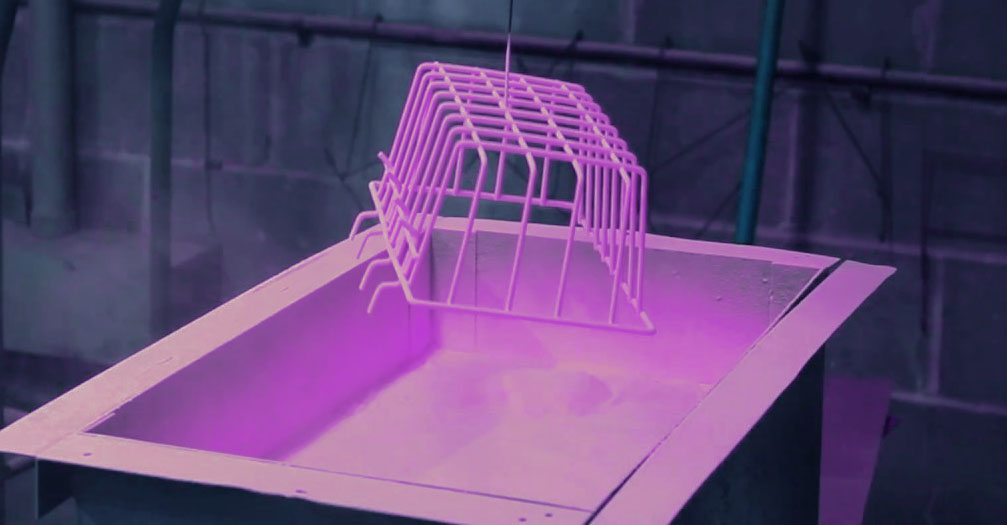

It is during this process that thermoset powders show why they are so useful. As the powder heats and melts, it flows around the surface of the object being coated, and undergoes a chemical change called cross-linking, which forms a tough, solid surface that protects the object being coated.

It is this process, with the chemical change, that make thermoset powder an effective coating for all kinds of objects, providing a number of protective qualities as well as visual appeal. The exact nature of the protection depends on the type of thermoset powder being used, with different formula being chosen depending on the requirements for the coating project.

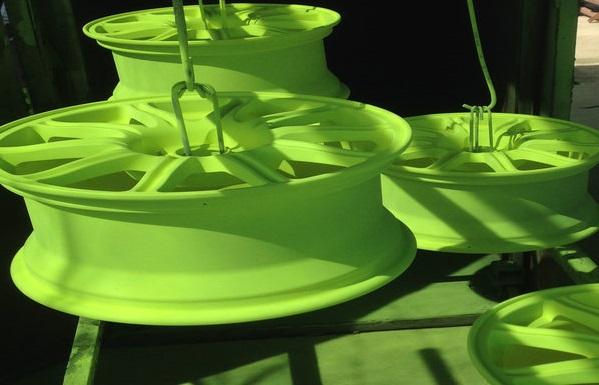

There are several types of thermoset powder, derived from epoxies, acrylics, hydroxyls (polyester) and carboxyl (polyurethane) groups, although the most common are epoxy and polyester based options. Epoxy resin based thermoset powders form a tough impact resistant coating that has excellent corrosion resistance, however they also tend to display poor UV resistance, so are most frequently used for internal applications as the color and gloss finish tend to degrade quite quickly when exposed to direct sunlight.

Polyester-based coatings share the same tough performance once cured, but are highly UV resistant, making them an ideal choice for outdoor applications. Other forms of thermoset powder have a variety of performance capabilities that are used for specific situations.

Rapid Offers Thermoset Powder has wide varietys -

- Epoxy Polyester Powder

- Pure Polyester Industrial Powder

- Pure Polyester Archiectural Powder

- Polyurethane Powder

- Anti Graffiti Powder

- Wood Finish Powder

- Zinc Rich Powder Coatings

- Fusion Bonded Epoxy Powders

- ValCoat Powder Coatings

- Insulation Grade Powder Coatings

- Anti-Microbial Power Coatings

- Low Bake Powder Coatings