Rapid Engineering Company Pvt Ltd

Rapid Engineering Company Pvt Ltd

A-11/1, Site-IV, Madan Mohan Malviya Marg

Sahibabad 201010

India

Telephone+91 72900 35860

About us

Rapid Engineering Co. is based out of INDIA and has been in business since 1974.

Rapid produces the following products:

1. Thermoplastic Polyethylene based Powder Coatings for dip coating and electrostatic spray coating.

2. Thermosetting Epoxy / Polyester Powder Coatings

3. Plastic Masterbatches

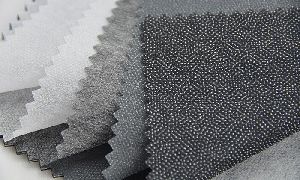

4. Adhesive Powders for coating on textiles, lamination and interlining fabric.

- These powders are available in LDPE, LLDPE, HDPE, PET, PS, PP, EVA polymers.

- The polymers are Cryogenically Pulverized into very fine powder.

Key Srengths of Rapid:

- 50 Years of experience in the plastic industry

- Capability to produce for very demanding and challenging applications.

- R&D / Analytical capability to improve product performance and quality (FTIR, DSC, TGA, XRF, QUV, Laser Particle Size Analyser).

- An extensive range of hotmelt adhesives in form of powders, pellets. Adhesives Powders/Pellets are made of TPU, EVA, HDPE, LDPE as well as designed as thermoplastic blends. These hotmelts are used in the automotive, construction and building, leather and textile industries.

- Exports to 35+ countries since the past 25+ years

- 350+ employees

- Government of INDIA Recognized EXPORT HOUSE

WWW.RAPIDPOLYMERS.COM

WWW.ADHESIVEPOWDERS.COM

Our product groups

- Bondtec (Surface & Bonding Techniques)

Our application areas / Solutions

Keywords

- Adhesive Powder, EVA Powder, TPU Powder, LDPE Powder

- Fusible Interlining Fabric, Textile Coating, Lamination

- Plastic Masterbatches, UV Masterbatch, Colour Masterbatch, White Masterbatch

- Hot Melt Adhesive, Thermoplastic Powder

- Non-woven colour masterbatch, Spun bonded masterbatch

Our Products

Hot Melt Adhesive Powder

A special cryogenically pulverized grade of thermoplastic powder has been developed for the textile application. Cryogenically pulverized powder provides low processing temperature and high elasticity. Our products suit Shoe Interlining, Leather Bonding, Shoe Soles, Lamination with non-woven etc.

- EVA Powder - Rapid offers cryogenically pulverized EVA Powder which is characterized by different VA (Vinyl Acetate) content. This determines the primary properties of the product. EVA is highly used as a hot melt adhesive because of its low processing temperature and high elasticity.

- Polyethylene Powder - We have a broad range of PE powder from Low to High. PE powders are available in different desired Particle Size Ranges.

- TPU Powder - Rapid offers cryogenically pulverized “Thermoplastic Polyurethane” powder which has good elasticity and is suitable for "Conveyor Belts". We have DTF Powder for Transfer Printing.

- Polypropylene Powder - Rapid offers cryogenically pulverized Polypropylene Powder for the production of temperature-resistant coatings and lamination.

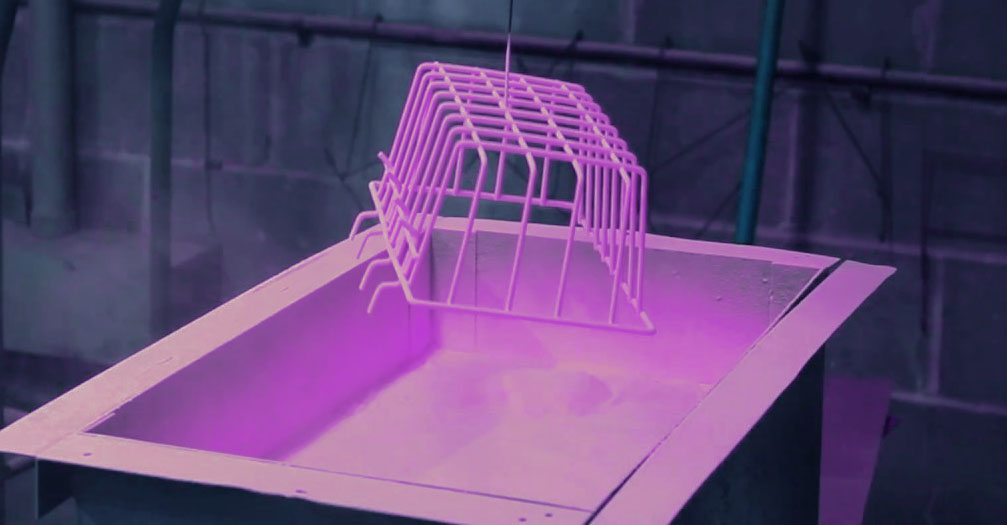

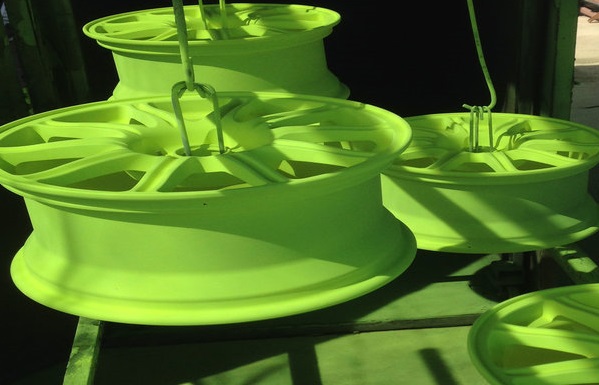

Thermoplastic Powder for Metals

Thermoplastic coatings offer the ultimate protection of metal structure against corrosion, wear and tear and chemical attack. They outperform other coatings, especially in terms of extended lifetime duration, environmental impact and ability to protect metal from corrosion.

High Adhesion Polymer Alloy (HAPA) plastic coating powders have been specifically designed to provide a long lasting, chemically & mechanically tough coating for both exterior and interior applications. HAPA coatings are a superior choice when compared to the conventionally used PVC and Polyester Coatings. The Coating has excellent adhesion to the base metal and is almost impossible to peel off.

Our HAPA powder are designed for toughness and chip resistance, without a primer. Applied as a single layer, fulfill the most demanding corrosion protection requirements: from heavy-duty industrial environments to offshore needs. HAPA are up to the challenge.

Features:-

- Resistance to all climate conditions, no corrosion even on damaged parts

- High impact and abrasion resistance

- UV stability and Excellent chemical resistance

- Electrical insulation and Maintenance free

- Easy to apply and economical

- Better coating coverage

- No cracking or peeling

- Food and water contact compliant

- Enhanced temperature resistance

- Wide colour selection and attractive finish

Masterbatches for Non-woven Fabrics

Rapid has cost effective solutions to enhance product’s visual appearance, functionality and performance depending on the nature of requirement. Rapid color masterbatches are developed from high quality pigments which provides the product excellent dispersion and quality. Our colour masterbatches are used for different applications which comply with required regulatory compliances.

Rapid Non-Woven Masterbatches Features -

- No Colour Fading

- Excellent dispersion thereby removing any processing error and get absolutely consistent result better after batches.

- Very good spinnability in the every batch Masterbatches.

- No risk of any electrostatic charge formation.

- Entire products available under one roof.

Cryogenic/Ambient Pulverizing

Rapid Engineering Co. Pvt. Ltd. has been offering Thermoplastic & Thermosetting Coating Powder for years to the coating segment and brings a unique combination of experience, from formulation to powder manufacture and application knowledge.

In 2019, Rapid Polymers was formed to manufacture Cryogenically Pulverized plastic powder with fully equipped laboratory and Cryogenic Plant. Rapid Polymers provide powder with excellent qualities in the terms of adhesion on metal, chemical resistance, long lasting & effective protection.

Rapid Polymers offer pulverising of your products to your required particle size, ranging from coarse powders to fine powders. We offer both cryogenic grinding as well as ambient grinding in-house in our different production facilities. Cryogenic grinding is performed using liquid nitrogen whereas ambient grinding is performed at room temperatures.

Thermoset Powder Coating

It is during this process that thermoset powders show why they are so useful. As the powder heats and melts, it flows around the surface of the object being coated, and undergoes a chemical change called cross-linking, which forms a tough, solid surface that protects the object being coated.

It is this process, with the chemical change, that make thermoset powder an effective coating for all kinds of objects, providing a number of protective qualities as well as visual appeal. The exact nature of the protection depends on the type of thermoset powder being used, with different formula being chosen depending on the requirements for the coating project.

There are several types of thermoset powder, derived from epoxies, acrylics, hydroxyls (polyester) and carboxyl (polyurethane) groups, although the most common are epoxy and polyester based options. Epoxy resin based thermoset powders form a tough impact resistant coating that has excellent corrosion resistance, however they also tend to display poor UV resistance, so are most frequently used for internal applications as the color and gloss finish tend to degrade quite quickly when exposed to direct sunlight.

Polyester-based coatings share the same tough performance once cured, but are highly UV resistant, making them an ideal choice for outdoor applications. Other forms of thermoset powder have a variety of performance capabilities that are used for specific situations.

Rapid Offers Thermoset Powder has wide varietys -

- Epoxy Polyester Powder

- Pure Polyester Industrial Powder

- Pure Polyester Archiectural Powder

- Polyurethane Powder

- Anti Graffiti Powder

- Wood Finish Powder

- Zinc Rich Powder Coatings

- Fusion Bonded Epoxy Powders

- ValCoat Powder Coatings

- Insulation Grade Powder Coatings

- Anti-Microbial Power Coatings

- Low Bake Powder Coatings

Our Contact Persons

Nav Jeevan Sharma

Export

Head of Department

Telephone+91 72900 35859

Anuj Gupta

Headquarters, Controlling

Managing Director

Telephone+91 96542 92975

Sumit Srivastav

Development

Head of Department

Mobile number+91 72900 35860