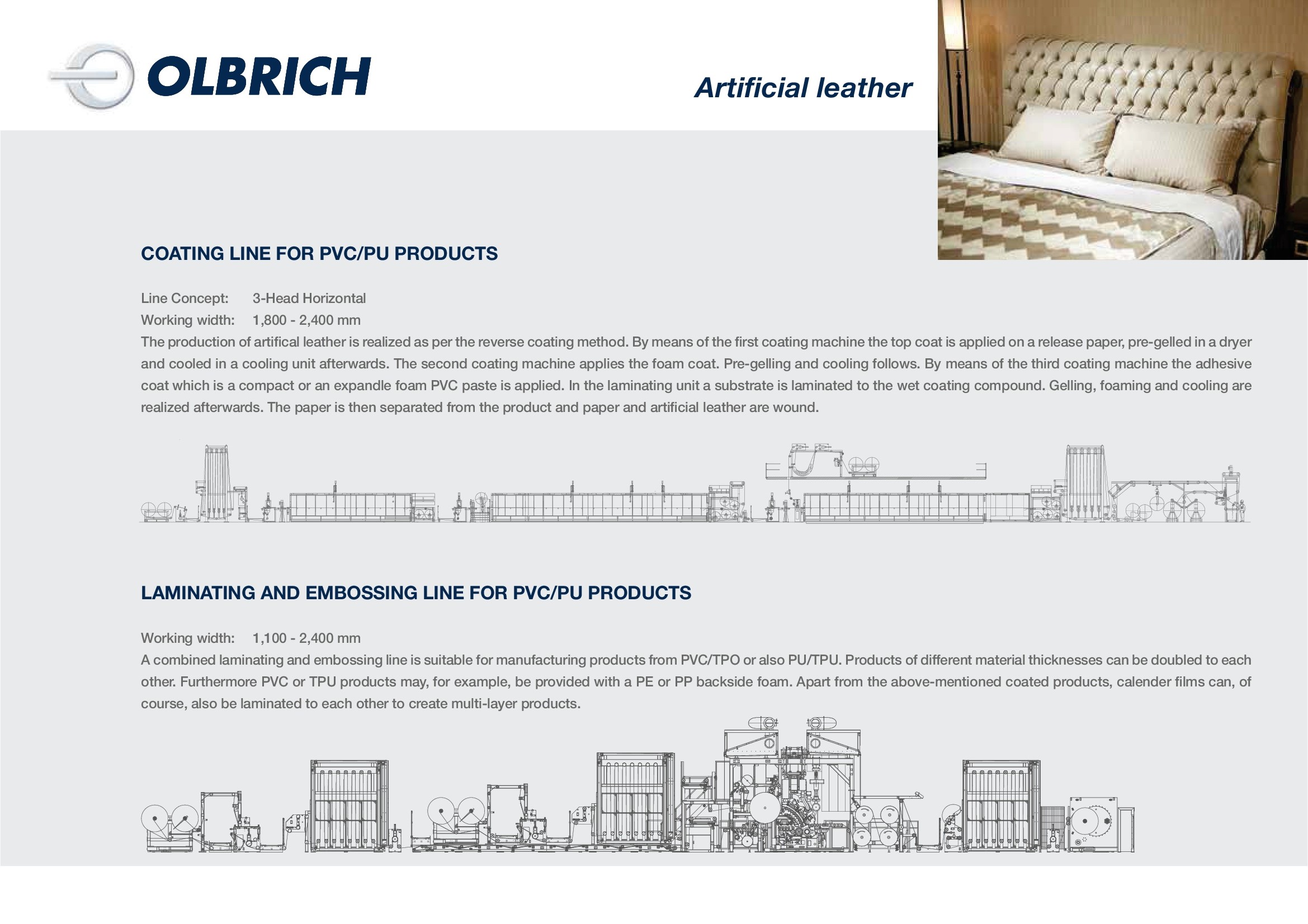

Artificial leather

Description

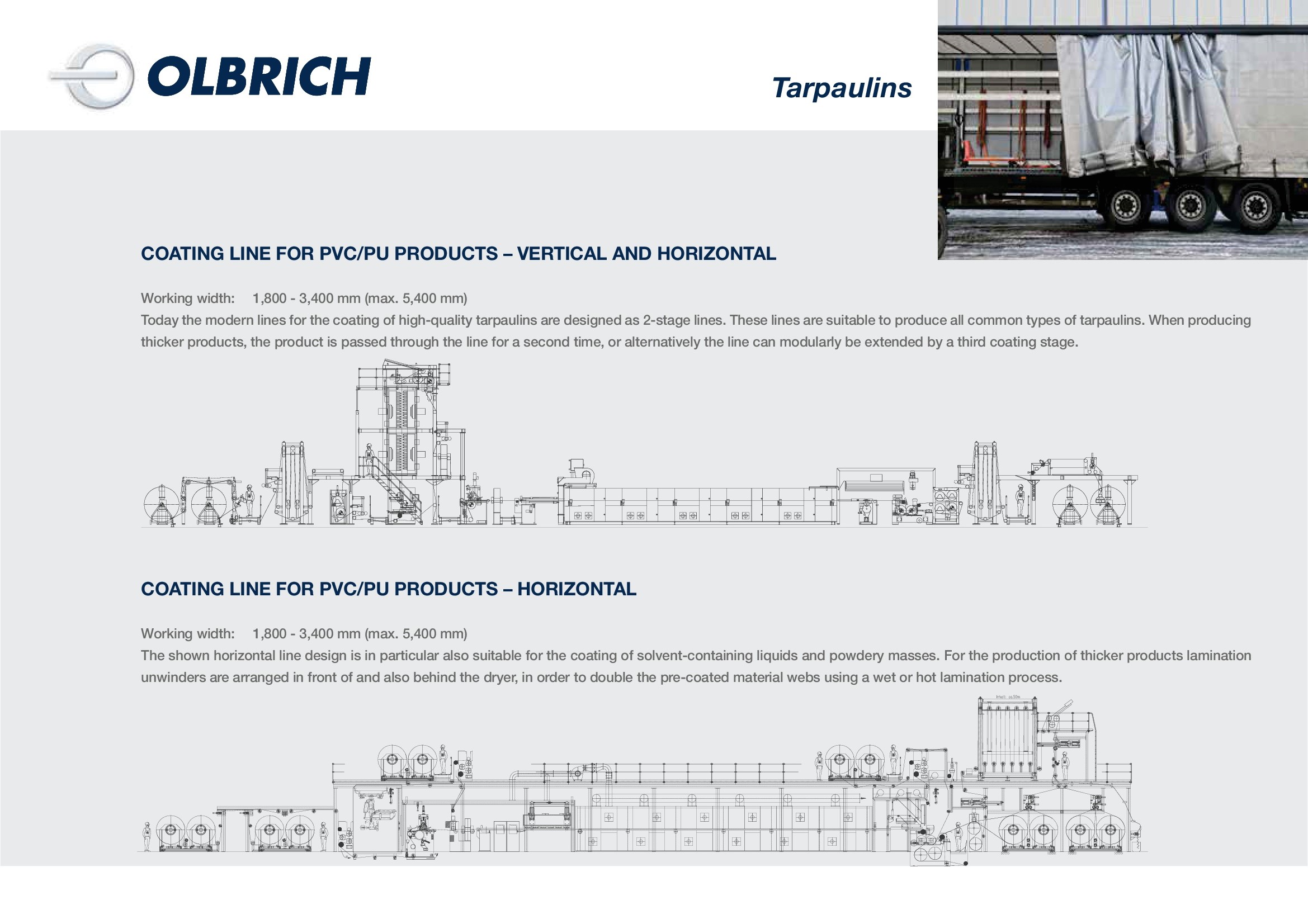

COATING LINE FOR PVC/PU PRODUCTS

The production of artifical leather is realized as per the reverse coating method. By means of the first coating machine the top coat is applied on a release paper, pre-gelled in a dryer and cooled in a cooling unit afterwards. The second coating machine applies the foam coat. Pre-gelling and cooling follows. By means of the third coating machine the adhesive coat which is a compact or an expandle foam PVC paste is applied. In the laminating unit a substrate is laminated to the wet coating compound. Gelling, foaming and cooling are realized afterwards. The paper is then separated from the product and paper and artificial leather are wound.

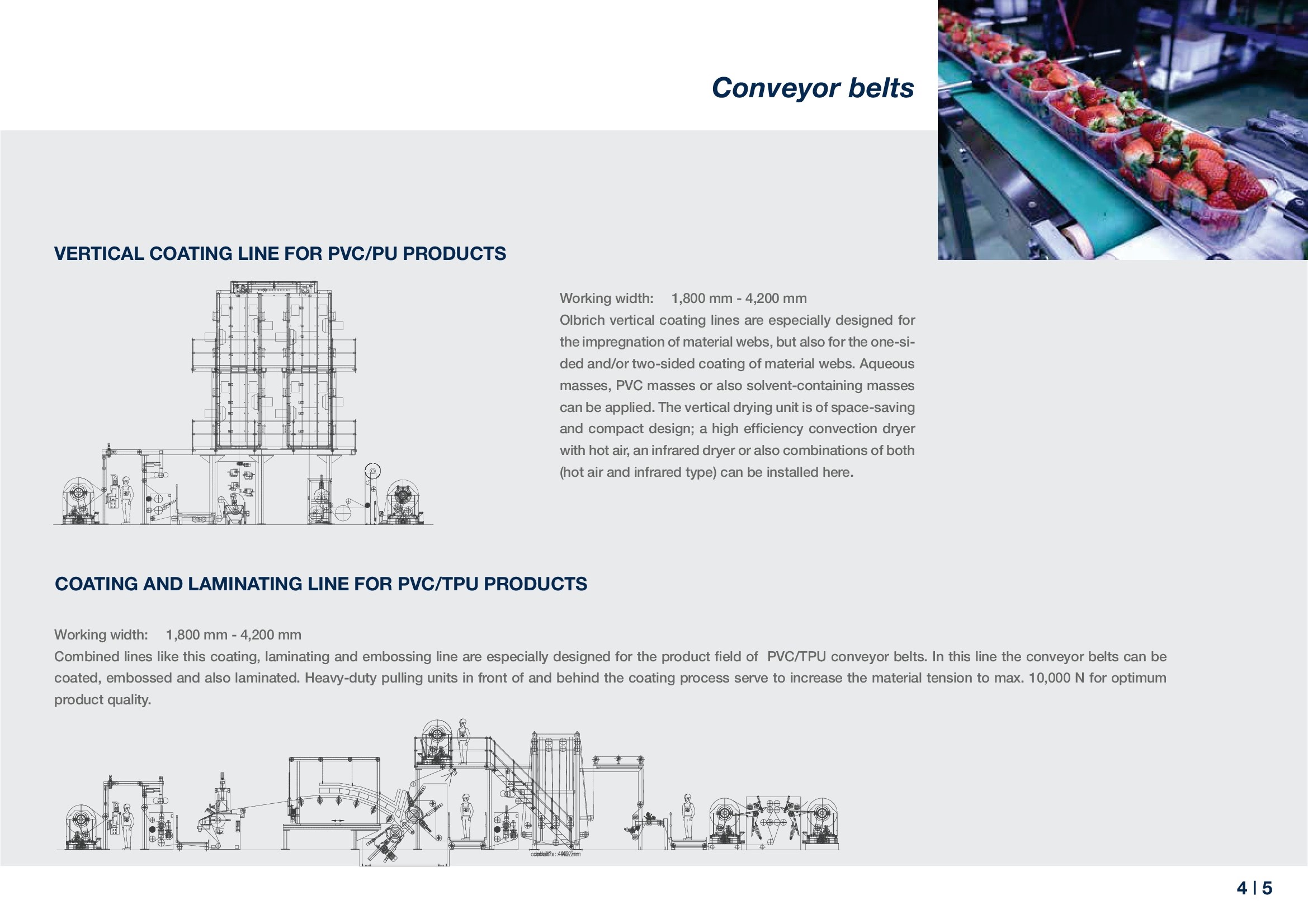

LAMINATING AND EMBOSSING LINE FOR PVC/PU PRODUCTS

A combined laminating and embossing line is suitable for manufacturing products from PVC/TPO or also PU/TPU. Products of different material thicknesses can be doubled to each other. Furthermore PVC or TPU products may, for example, be provided with a PE or PP backside foam. Apart from the above-mentioned coated products, calender films can, of course, also be laminated to each other to create multi-layer products.

Discover more from us