OLBRICH GmbH

Discover more from us

About us

Sophisticated Line Concepts for Maximal Capacity

Tailor-made line concepts for the highest production quality and maximum productivity:

That is what we offer to the technical textile industry. To achieve this, we revert to our comprehensive range of line components and elaborate an individual line concept, in co-operation with the customer and engineering partners. Thus Olbrich realises highly productive lines to achieve the highest capacity.

Our Customers‘ Products

- Tarpaulins for trucks and other applications

- Roof sheeting, reservoir lining

- Textile application, tents and blinds

- Billboards

- Printing blankets

- Boats / inflatable articles

- Functional textiles and protective clothing

- Conveyor belts / driving belts

- Other kinds of coating fabrics (special applications)

Line Concepts

- Inline-coating- and -lacquering lines

- Coating lines for PVC-/PU-/PTFE-coated products

- Coating lines for rubber-coated textiles

- Coating lines for artificial leather

- Lacquering lines

- Laminating lines

Technological Fields of Expertise

OLBRICH lines set standards in many branches. The reason for this is our comprehensive range of technological expertise which we are constantly expanding using our technical centre.

Drying

Coating

Printing

Winding

Embossing

Laminating

Lacquering

Calendering

Drives & Controls

Winding & Packaging

Our product groups

Our application areas / Solutions

Keywords

- PVC-Abdeckplanen/Side Curtains für LKWs / PVC tarpaulins and side curtains for trucks

- Textildruck / Textile printing

- Funktionstextilien und Schutzbekleidung / Functional textiles and protective clothing

- Kunstleder / Artificial leather

- Transport- und Förderbänder/Antriebsriemen / Conveyor belts/driving belts

Our Products

Tarpaulins

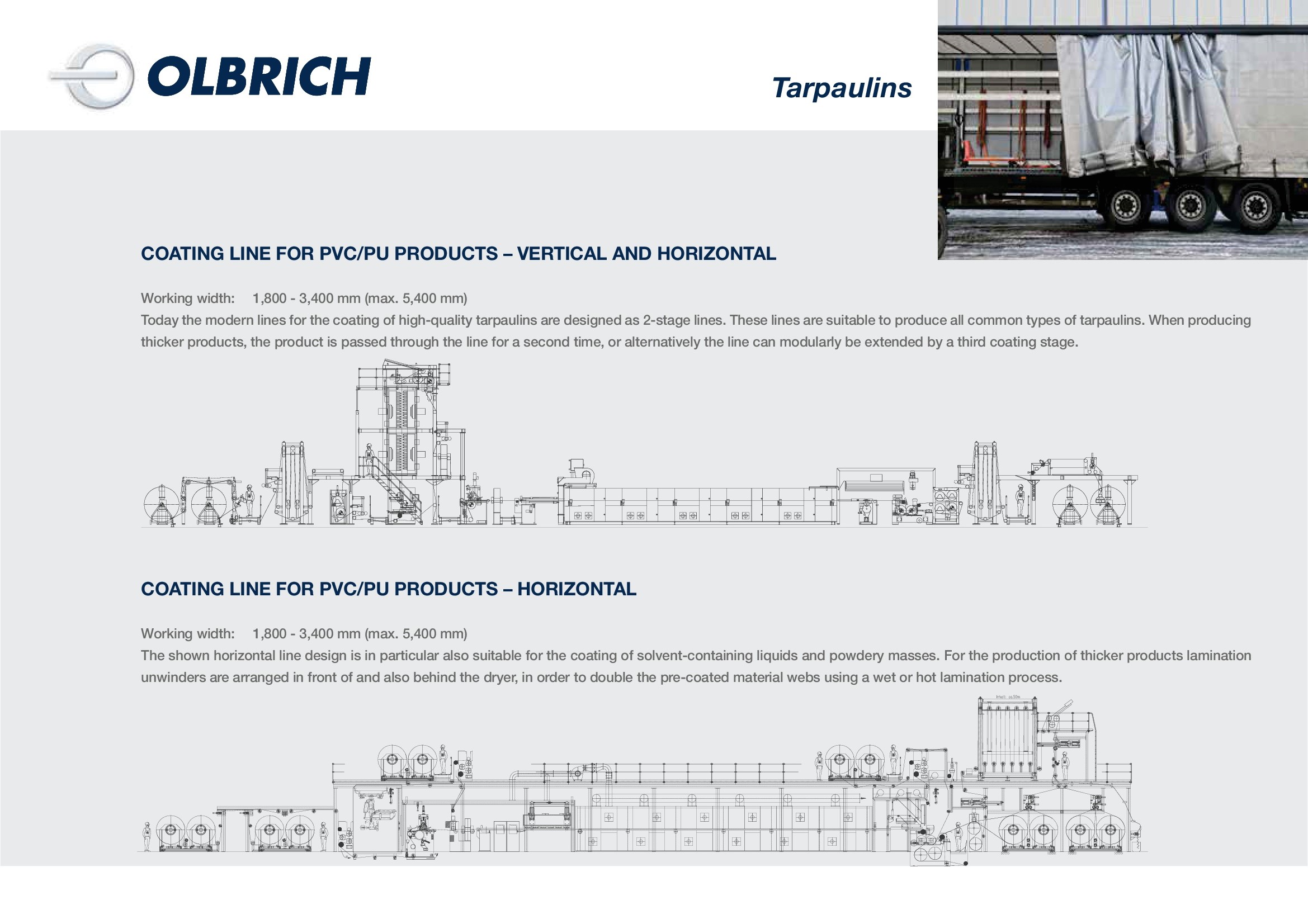

COATING LINE FOR PVC/PU PRODUCTS – VERTICAL AND HORIZONTAL

Today the modern lines for the coating of high-quality tarpaulins are designed as 2-stage lines. These lines are suitable to produce all common types of tarpaulins. When producing thicker products, the product is passed through the line for a second time, or alternatively the line can modularly be extended by a third coating stage.

COATING LINE FOR PVC/PU PRODUCTS – HORIZONTAL

The shown horizontal line design is in particular also suitable for the coating of solvent-containing liquids and powdery masses. For the production of thicker products lamination unwinders are arranged in front of and also behind the dryer, in order to double the pre-coated material webs using a wet or hot lamination process.

Conveyor belts

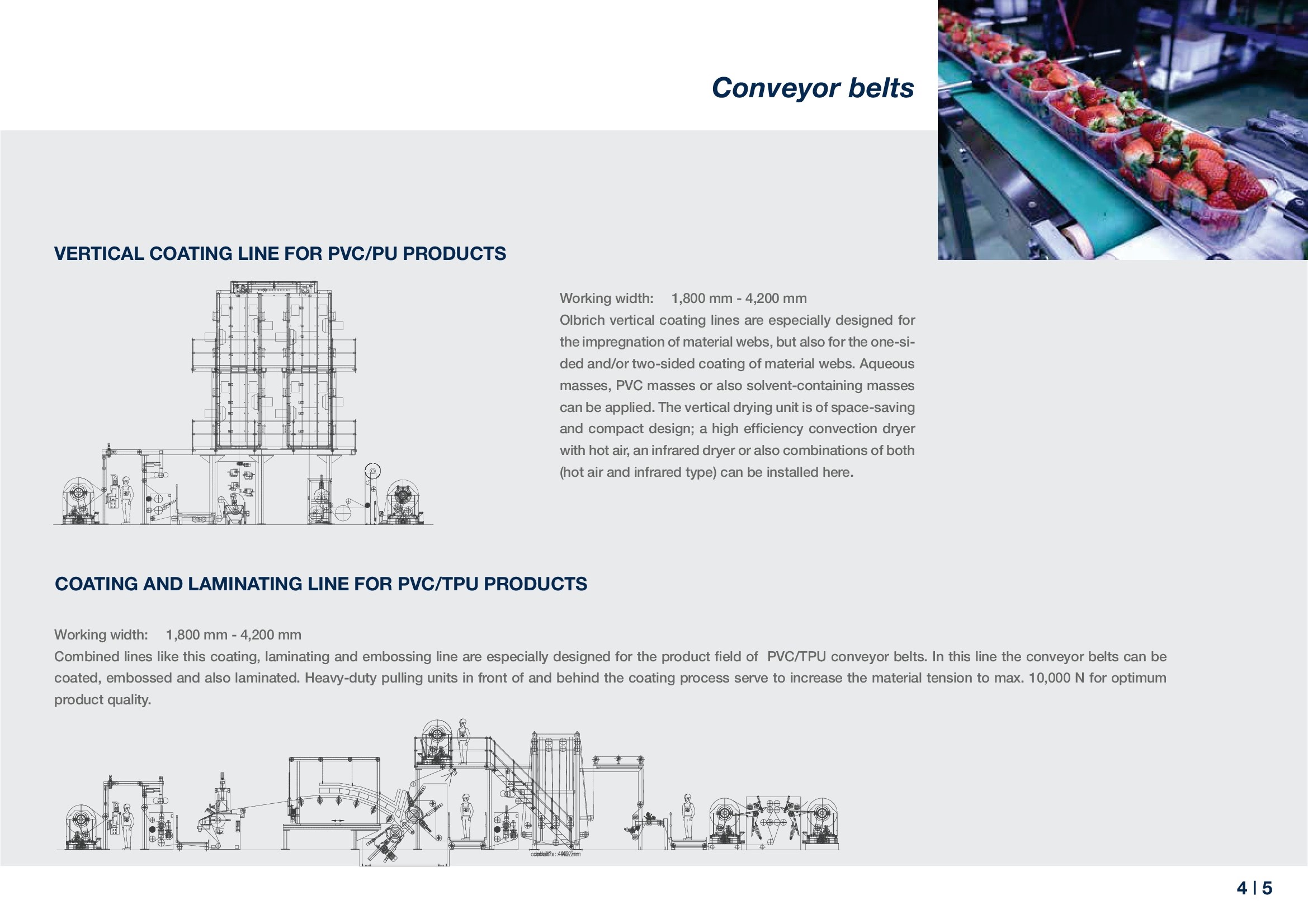

VERTICAL COATING LINE FOR PVC/PU PRODUCTS

Olbrich vertical coating lines are especially designed for the impregnation of material webs, but also for the one-sided and/or two-sided coating of material webs. Aqueous masses, PVC masses or also solvent-containing masses can be applied. The vertical drying unit is of space-saving and compact design; a high efficiency convection dryer with hot air, an infrared dryer or also combinations of both (hot air and infrared type) can be installed here.

COATING AND LAMINATING LINE FOR PVC/TPU PRODUCTS

Combined lines like this coating, laminating and embossing line are especially designed for the product field of PVC/TPU conveyor belts. In this line the conveyor belts can be

coated, embossed and also laminated. Heavy-duty pulling units in front of and behind the coating process serve to increase the material tension to max. 10,000 N for optimum

product quality.

Artificial leather

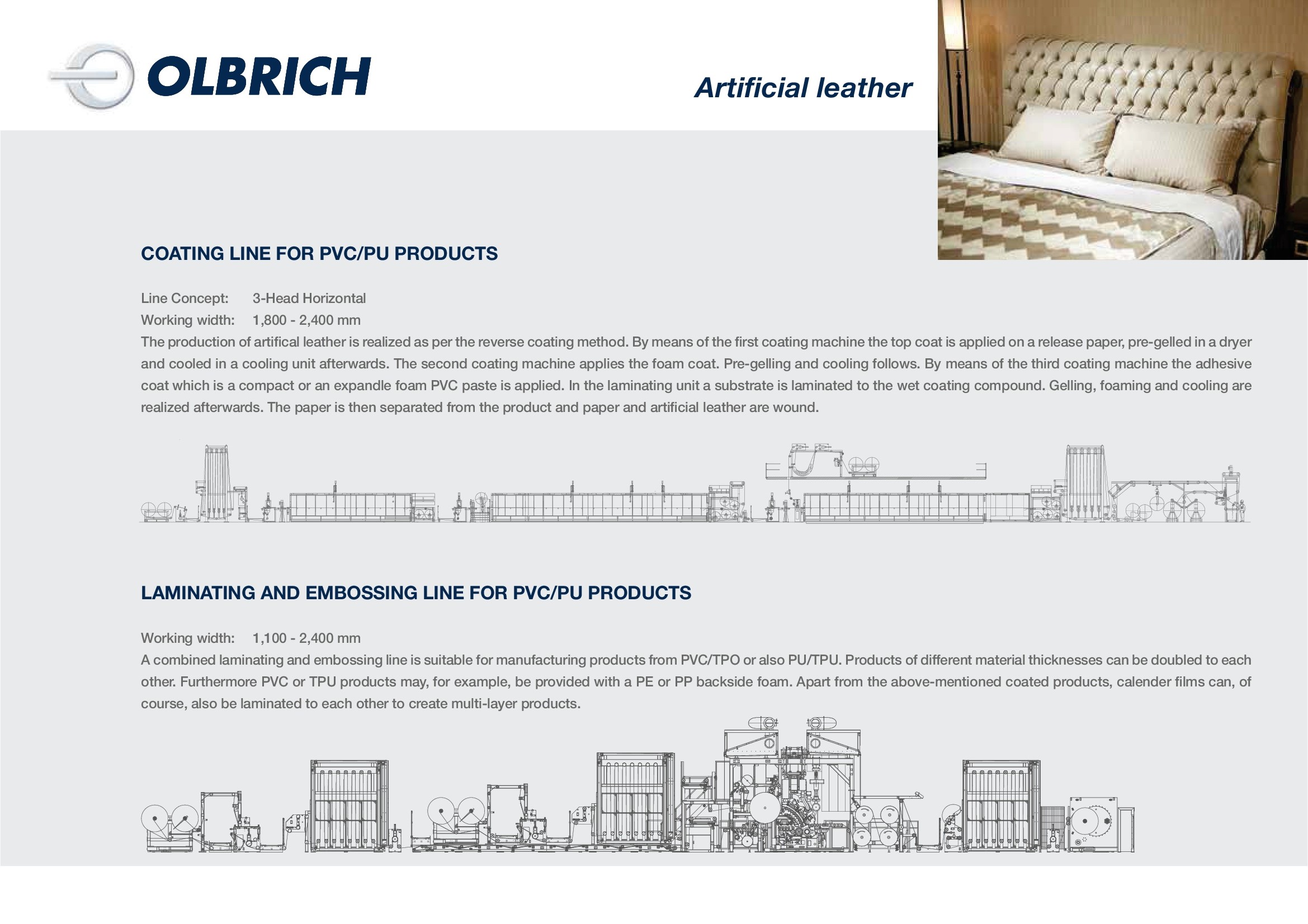

COATING LINE FOR PVC/PU PRODUCTS

The production of artifical leather is realized as per the reverse coating method. By means of the first coating machine the top coat is applied on a release paper, pre-gelled in a dryer and cooled in a cooling unit afterwards. The second coating machine applies the foam coat. Pre-gelling and cooling follows. By means of the third coating machine the adhesive coat which is a compact or an expandle foam PVC paste is applied. In the laminating unit a substrate is laminated to the wet coating compound. Gelling, foaming and cooling are realized afterwards. The paper is then separated from the product and paper and artificial leather are wound.

LAMINATING AND EMBOSSING LINE FOR PVC/PU PRODUCTS

A combined laminating and embossing line is suitable for manufacturing products from PVC/TPO or also PU/TPU. Products of different material thicknesses can be doubled to each other. Furthermore PVC or TPU products may, for example, be provided with a PE or PP backside foam. Apart from the above-mentioned coated products, calender films can, of course, also be laminated to each other to create multi-layer products.