Hotmelt lamination

Hotmelt lamination

Description

Hotmelt lamination is the most versatile method of joining materials, allowing the material to be joined without the use of foam as an adhesive. By using an adhesive, the laminated material becomes more resistant to tearing, washing and high temperatures, while maintaining the vapour permeability of the bonding layer.warstwy łączącej.

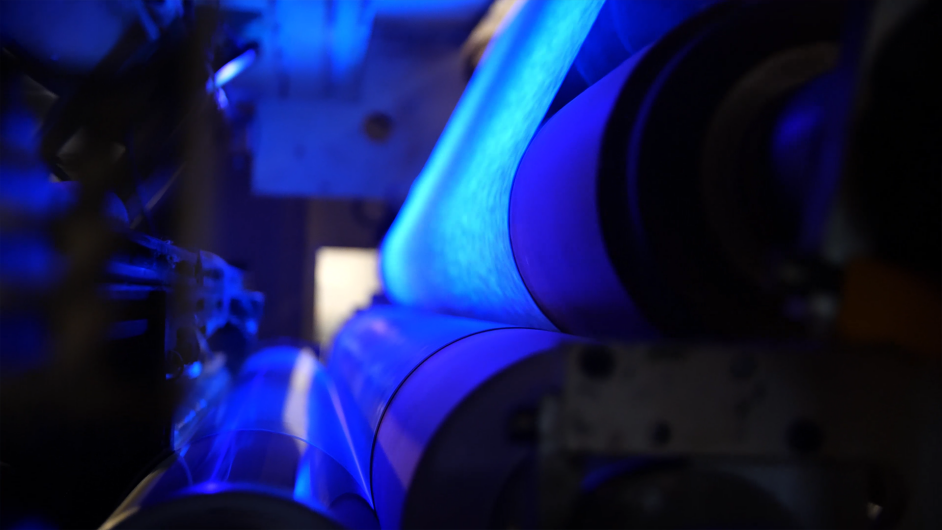

This state-of-the-art and fully controlled process uses a reactive adhesive that is suitably heated prior to the lamination and applied to the materials to be joined using an engraved roller. This ensures that the adhesive is evenly distributed and that the resulting textile system retains the properties of the individual components.

With Hotmelt lamination technology, our machinery allows the production of laminates up to 240 cm wide and 10-15 mm thick. Possible adhesive application ranges from 5 to 140 g/m2.