Kansan Makina Kagit San Ve Tic A.S.

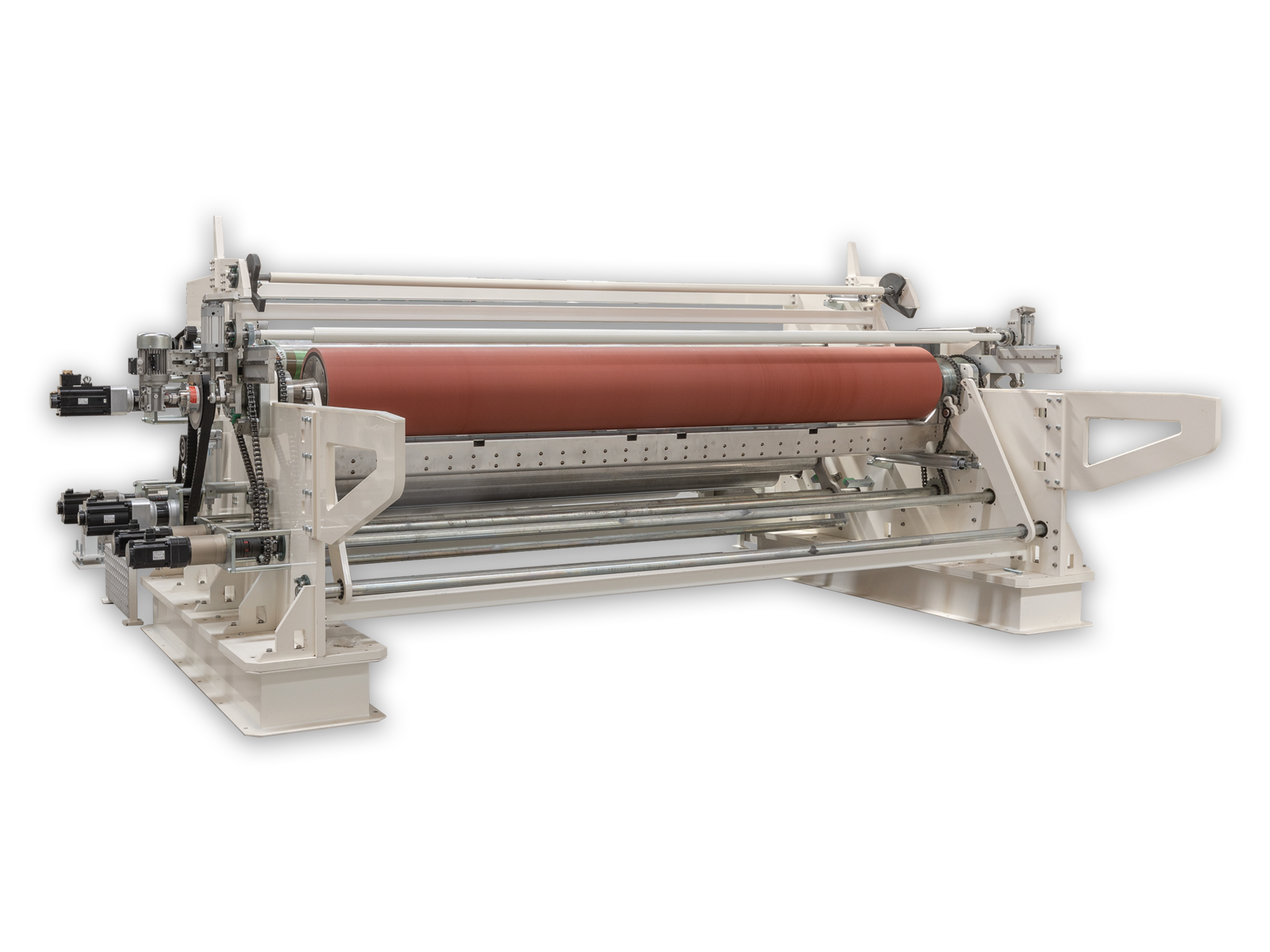

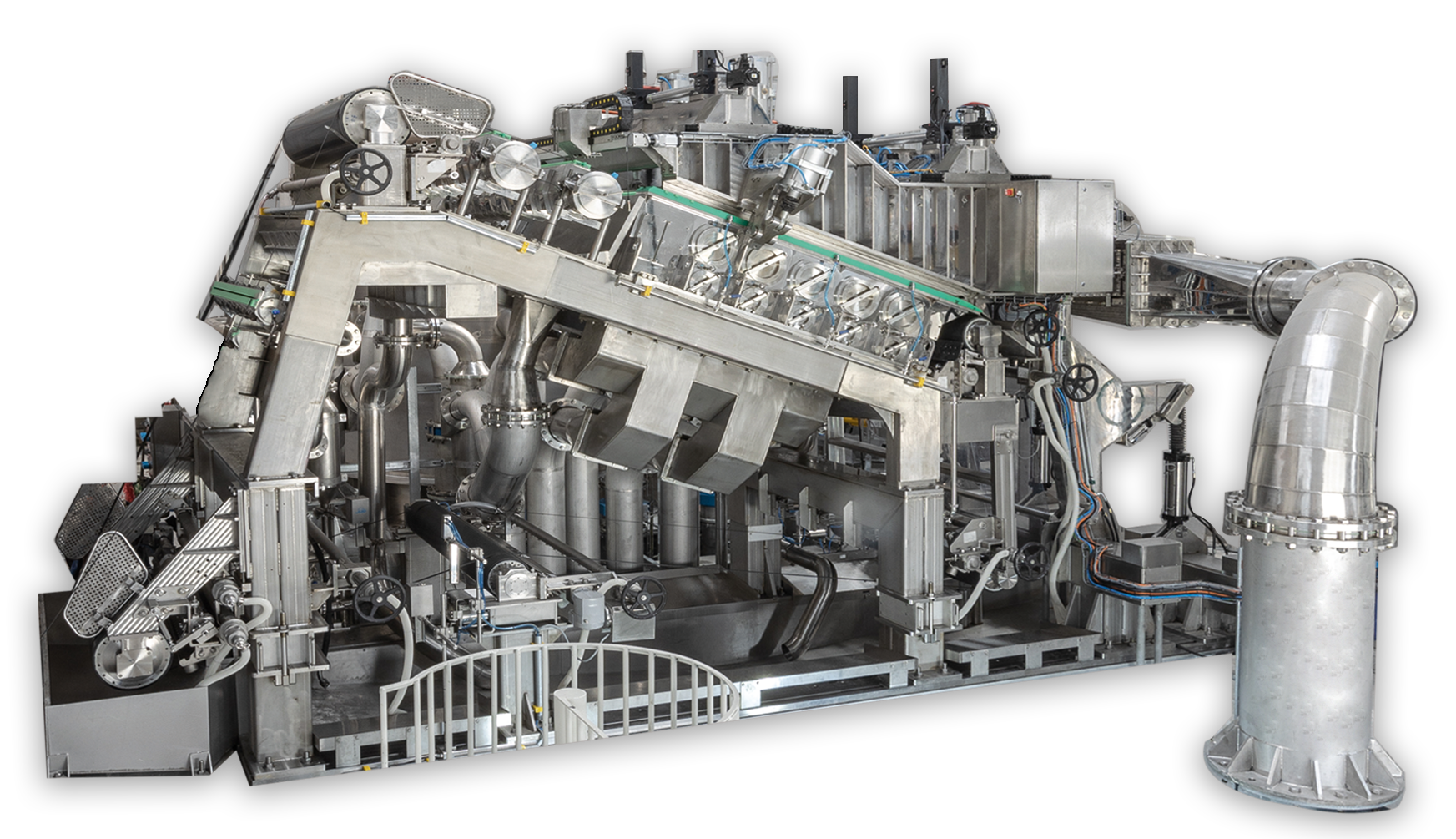

KM AquaFormer

Description

KM-Aquaformer is the most crucial component of a wetlaid production line. It performs the entire wet laying steps. Wet laying is a mature and the most effective method that has been used in paper and wetlaid nonwoven industries for quite some time. This method allows the production of nonwoven materials from renewable and cost-effective, eco-friendly fibers like cellulose and pulp.

Wet former’s process flow is as follows:

- Water with fibers in suspension from the white water tank is pumped to the headbox.

- Fibers are laid on the mesh belt under the headbox. An inclined headbox design is used for fiber distribution and spacing to be homogenous and consecutive. The dilution ratio of fibers in water is very critical and needs to be adjusted optimally. The ratio changes based on the fiber type and fiber lengths.

- The pumping and flow pressure must be stable to ensure a constant flow of fibers on the mesh belt. The water gets through the mesh and is sucked while the fibers stay atop and form the web.

- The main goal is to have a very uniform web formation with desired porosity through a perfect fiber distribution where each fiber lands right next to the other without so much overlapping or hindrance.

- The excess water then is being recycled back to the white water tank for cost and energy saving.

Hall12.0E29

See FloorplanAddress

Kansan Makina Kagit San Ve Tic A.S.

Capak Mahallesi No: 6

35860 Izmir

Türkiye