Fully Automatic Balling Machine HK

Fully Automatic Balling Machine HK

Description

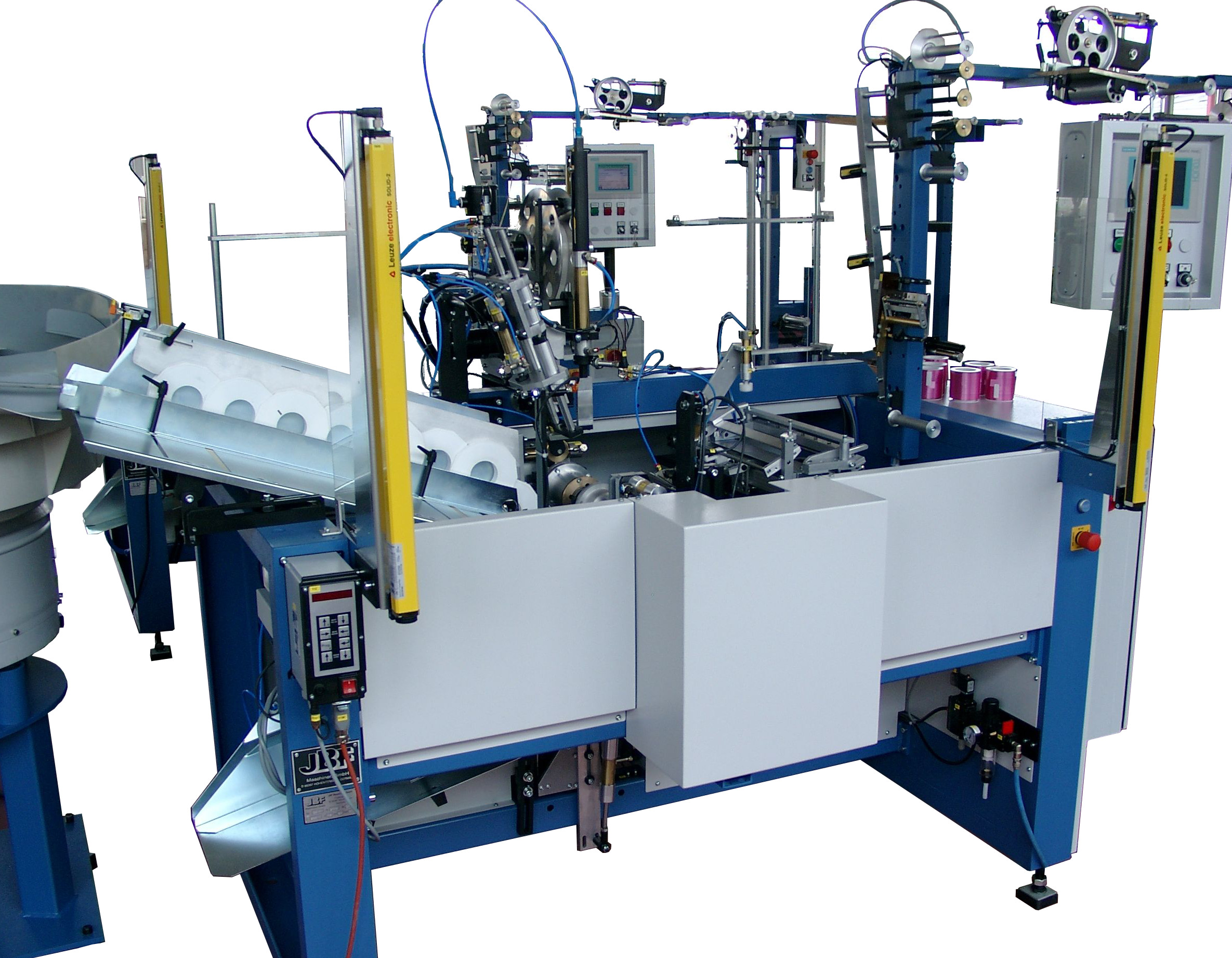

The electronically controlled Automatic Balling Machine HK with 6, 9 or 12 spindles processes in a fully automatic working cycle twines, strings and cords into balls of all common shapes within a weight range from 5 to 2000 grams (HK-6), 1500 grams (HK-9) or 500 grams (HK-12).

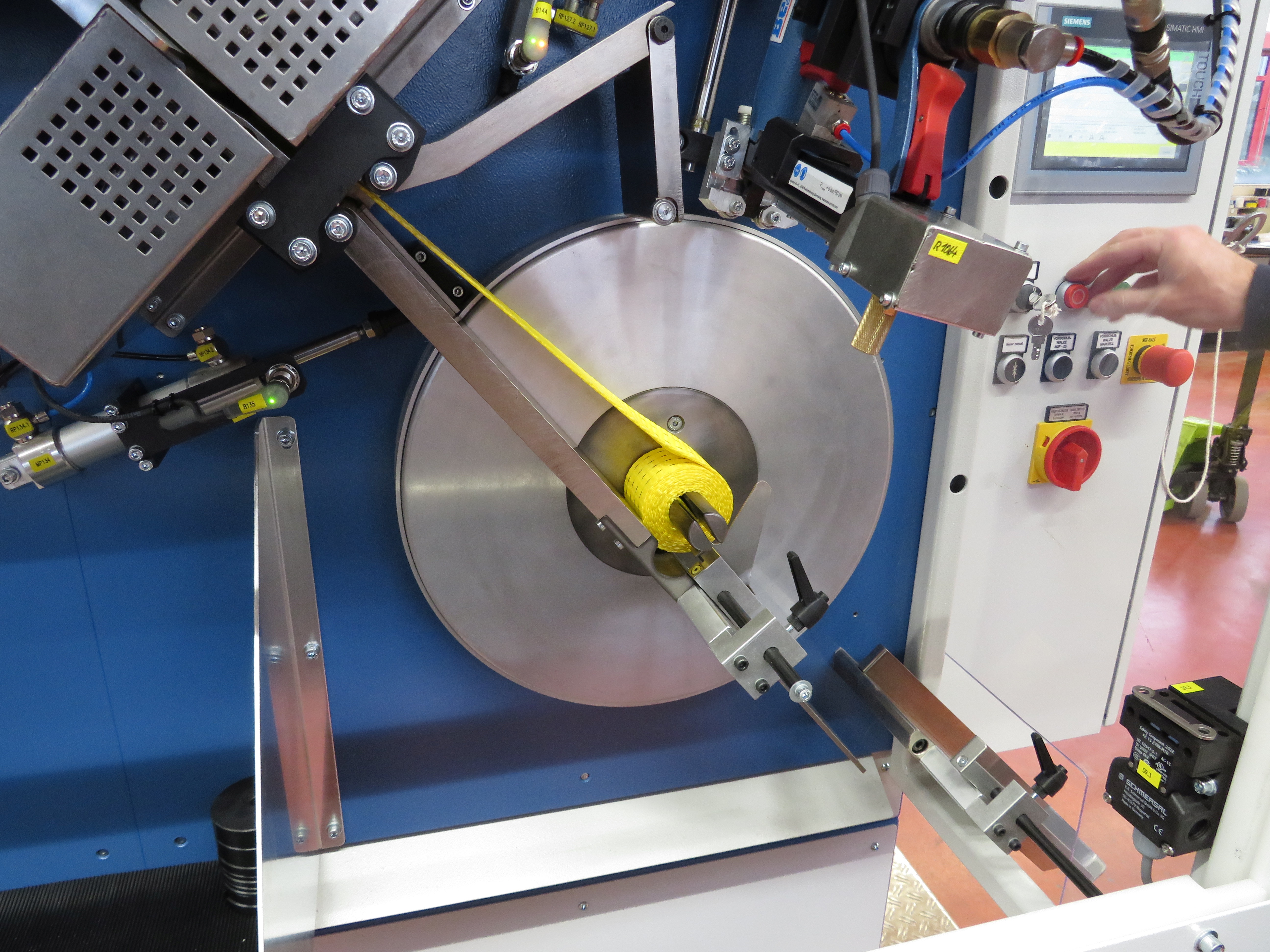

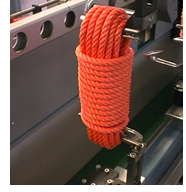

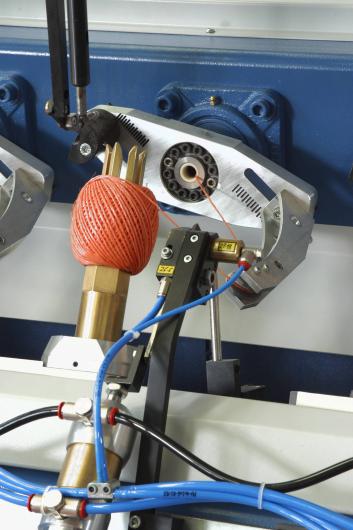

When starting the winding cycle the flyer makes a half turn and puts the twine in front of the winding mandrel. The slotted mandrel moves forward into winding position and threads the twine. After a few turns of the flyer the thread clamp releases the beginning of the twine which is then wound into the ball. All ball shapes and structures are infinitely adjustable through a raising and lowering of the mandrel beam. During the base winding the mandrel runs with increased speed. This results in a large twine laying grid and an increased ball volume. During the surface layer winding an automatic decrease of the mandrel speed results into a closed twine layer on the surface of the finished ball. The ratio mandrel revolutions to flyer revolutions can be adjusted at any mandrel beam position and stored into the operation panel storage place. With this option you can also produce “square” balls. The final circumference winding consists of parallel layers side by side on the surface of the ball. Optional there is the possibility to insert a label, tied down with the final circumference winding. The end of the twine is led into the insert hook and put into the open knife of the cutting device. The knife moves backwards, cuts the twine and at the same time clamps the twine-end for the next winding cycle. The insert hook moves backwards and draws in the twine in loop shape under the circumference winding. The winding cycle is finished and the ball is doffed with a draw- back movement of the winding mandrel.

All ball parameters like running-length mandrel-beam-position, winding speed etc. can be stored in up to 99 storage places for shortest change-over-times.