The exhibitors & products at Techtextil 2026 will be available here from mid-January 2026.

Description

SillverSan® - OxyCat®

OxyCat®- catalysts are used to keep water fresh and for water treatment. What they all have in common is the surface modified according to the patented SilverSan® process with unique catalytic activity in aqueous media even at low temperatures. Due to its high redox potential, it has a repellent effect on microorganisms. This repellent effect explains the high protective effect against biofilm

The core piece is the silver wire coated with OxyCat®. It is a wire with > 99% Ag and a diameter of 0.1mm.

The core application is to keep household appliances, drinking water dispensers, bottles, canisters, air filtration etc. fresh. The point of use is any direct contact with treated water.

If the manufacturer`s cleaning instructions are followed, the product remains usable for up to six months.

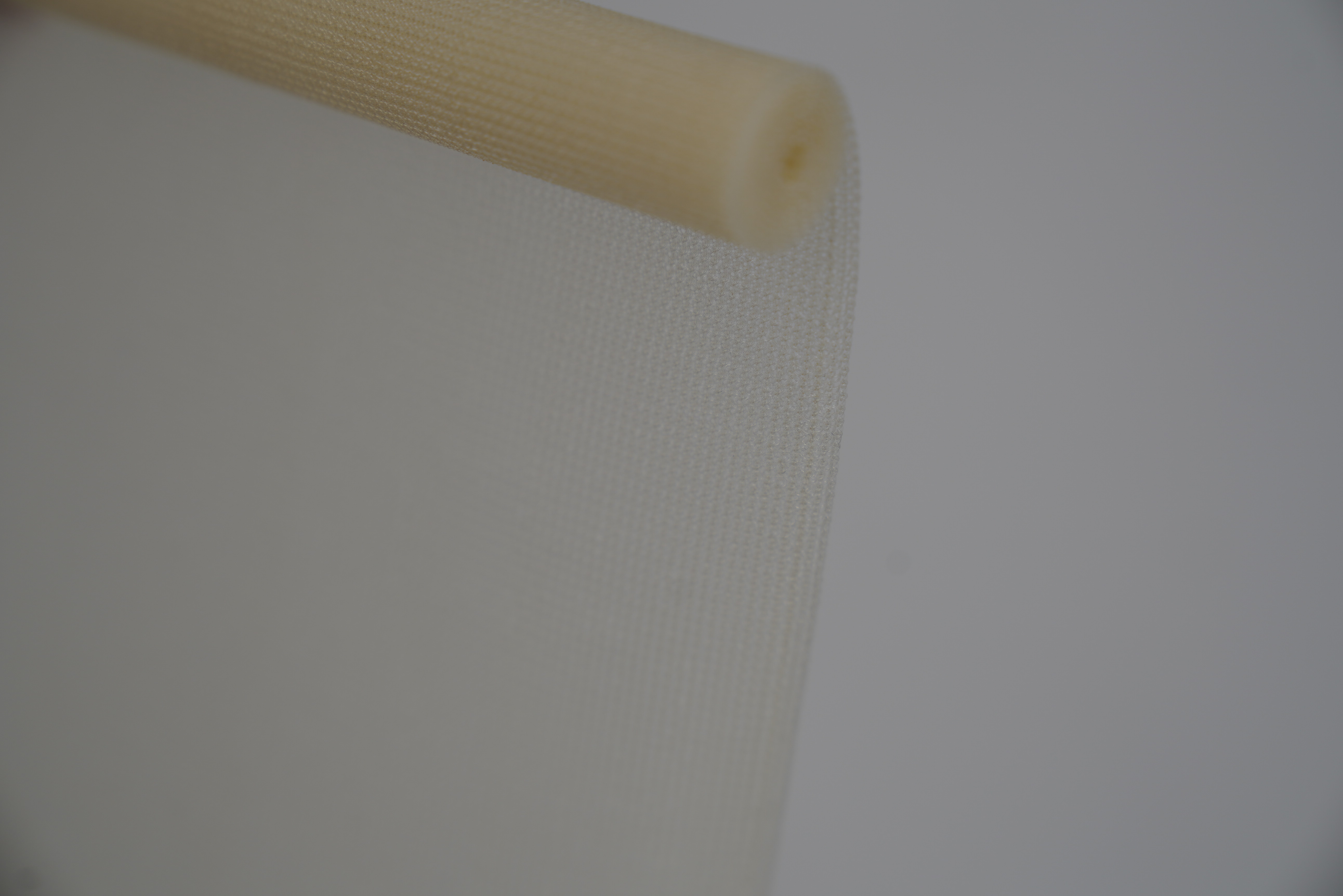

SilverSan® - OxyCat® technology can be integrated into the following textile constructions: Braid with one silver thread (see picture), upgradeable to a maximum of 8 silver threads.

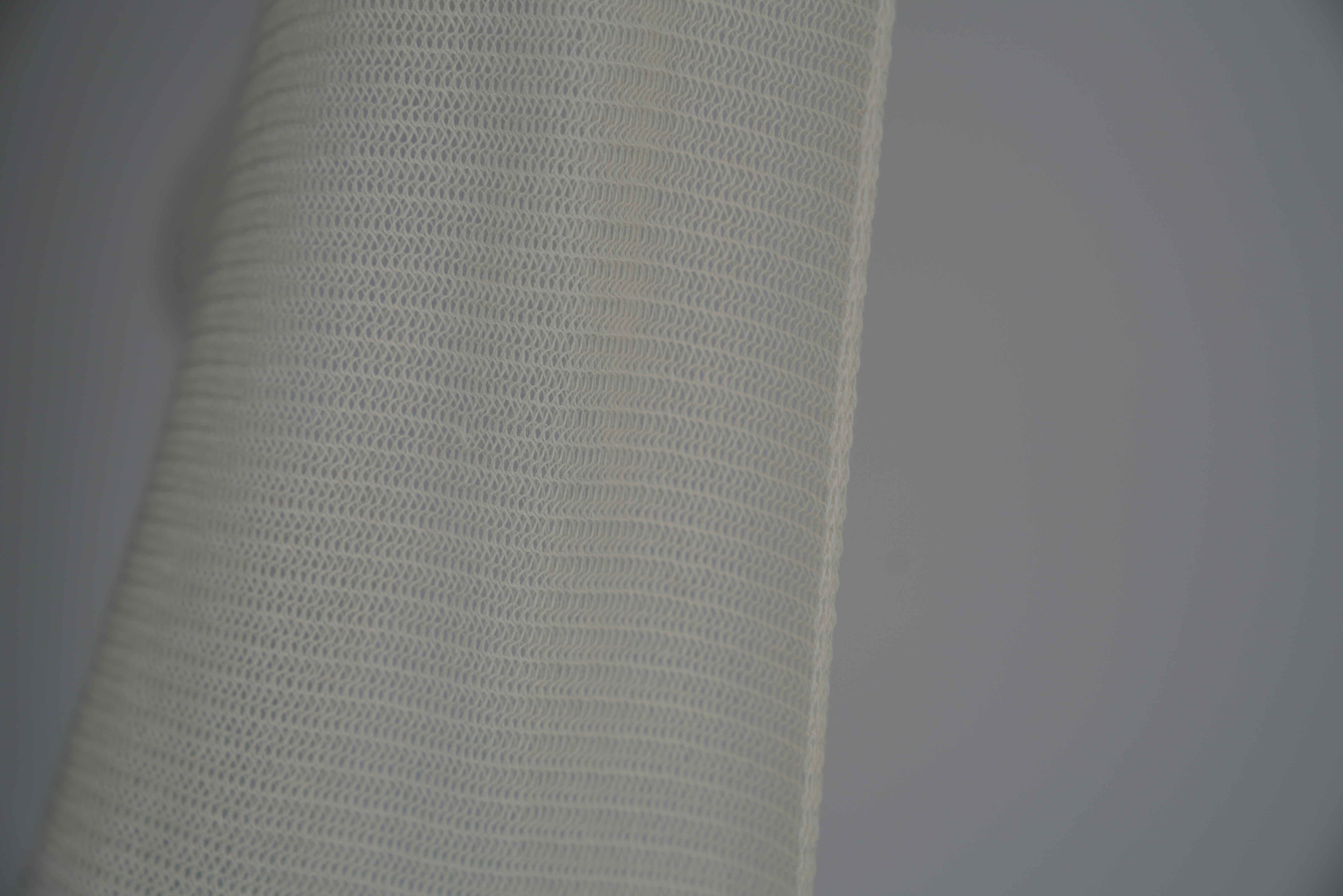

Knitted fabric, cord (typical applications “wrapping”/”in-tube”), knitted fabric, woven fabric