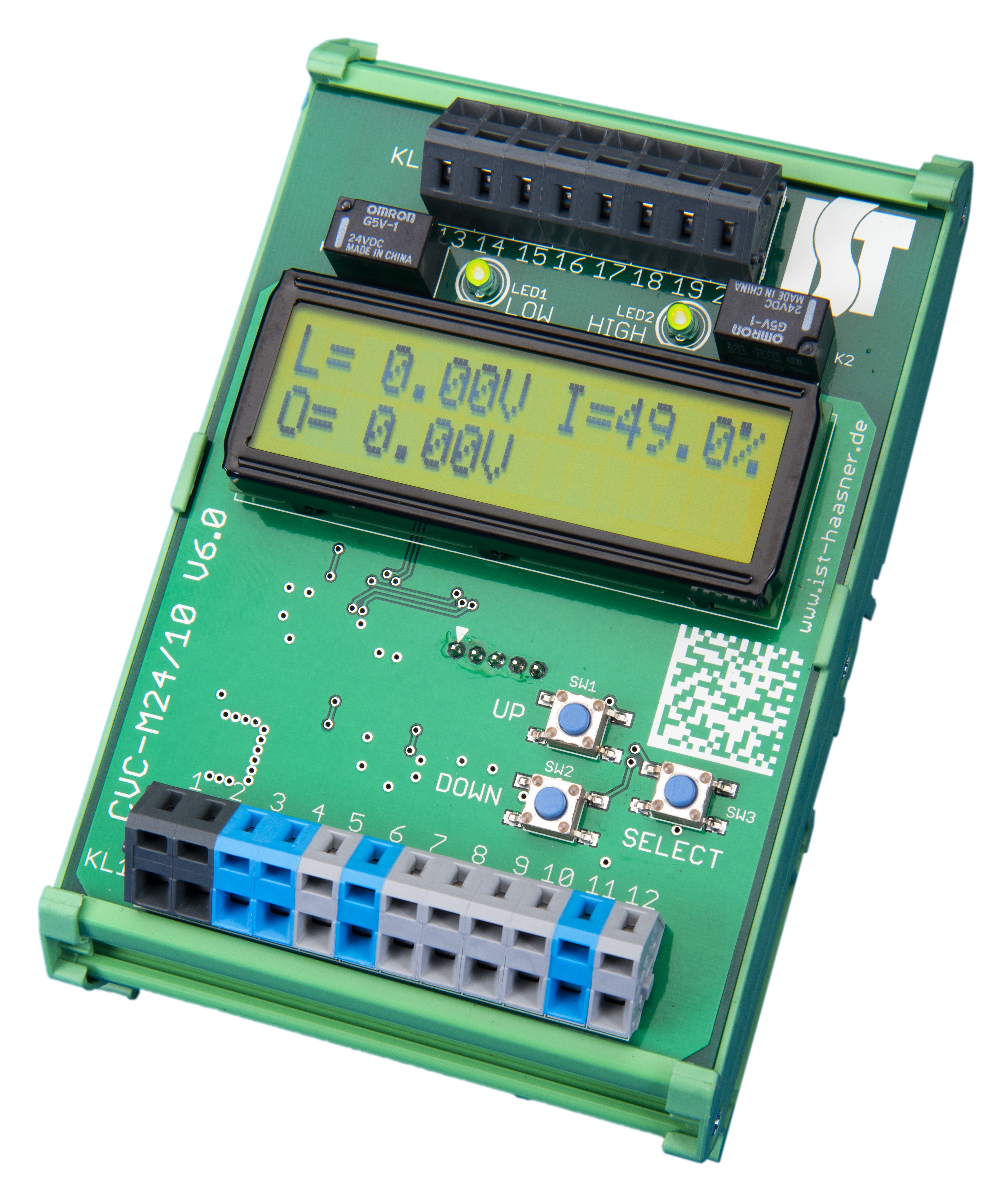

CVC-Modul 6.0

Description

Our original CVC 1.0 module was developed at the beginning of 2000 with the function of evaluating the signal from our INKL 1.0 inclinometer. Over the years, the module has been developed progressively to the current version, CVC 6.0.

The Up and Down buttons are used for navigation to the individual menu items. The Select button is used to select the parameter (refer to the description of CVC 6.0).

Two relay outputs for the Min and Max range can be read into the PLC or integrated into the customer’s existing conventional control system.

Contactless tracing of a compensator roller

The traditional detection of the compensator roller position with continuous plants is carried out by means of the magnetoresistor potentiometer (FP). This FP is connected with the swinging axle in a given determined ratio of transmission by means of toothed belt or chain. lmportant mechanical energy is used to transmit the electric signal in function of the position of the compensator roller (PW) to the control. 2 signalling lines have to be drawn to each magnetoresistor potentiometer. The first one is needed to detect the voltage signal and the second one to detect the final positions of the compensator roller (above/below). lf the machines are still new and the compensator rollers have been adjusted correctly, the plant functions without any problems.

During later after sales-service works, often problems occur with the exact adjusting of the limit switches or the normal route of the potentiometer. ln addition, mechanical sources of error may arise (i.e., wear of the connection between the magnetoresistor potentiometer and the compensator roller), which may lead to a false signal transmission. All these problems can be avoided with our new inclinometer owing to the fact that it is directly mounted on the swinging axle. When moving the compensator roller, the axle rotates and the output signal changes. The inclinometer converts an angle of +/- 45° (0...90°) against the vertical axis into a linear proportional voltage. The inclinometer case is made of special steel and can be used in the photographic-, dyeing-, oil-, soap-, paper- and textile industry. One signalling line is sufficient for detecting the voltage signal.

Up to now this voltage signal could only be evaluated in connection with an SPS. From now on, you will be able to evaluate without SPS by means of our new electronic card the constant voltage signal in function of the line speed. This card has been specially designed to retrofit old plants. With a distribution voltage of 24V D.C. the card can be retrofitted into all switchboards. The detection of the final position of the compensator roller is pre-optimised on the electron- d ic card so that inside the switchboard the monitoring of the compensator roller can be directly involved into the control.

ln case of a new assembly the wiring of an additional line for the limit switches is not necessary. Thus, you can save time and money when using our new components. Of course, you can also evaluate other signals by means of these components as, for instance, with the loop control of a carpet range at the run-in ,,Steamer". Here, too the signal is detected and converted such that it directly controls the sequential drive.

When using our products the susceptance to trouble is decreased and the reliability of operation is increased which results in a better availability of your plant.

Address

IST, Industrielle System Technik Michael Haasner GmbH & Co. KG

Siemensstr. 20

47608 Geldern

Germany

Telephone+49 2831 977720

Fax+49 2831 9777222