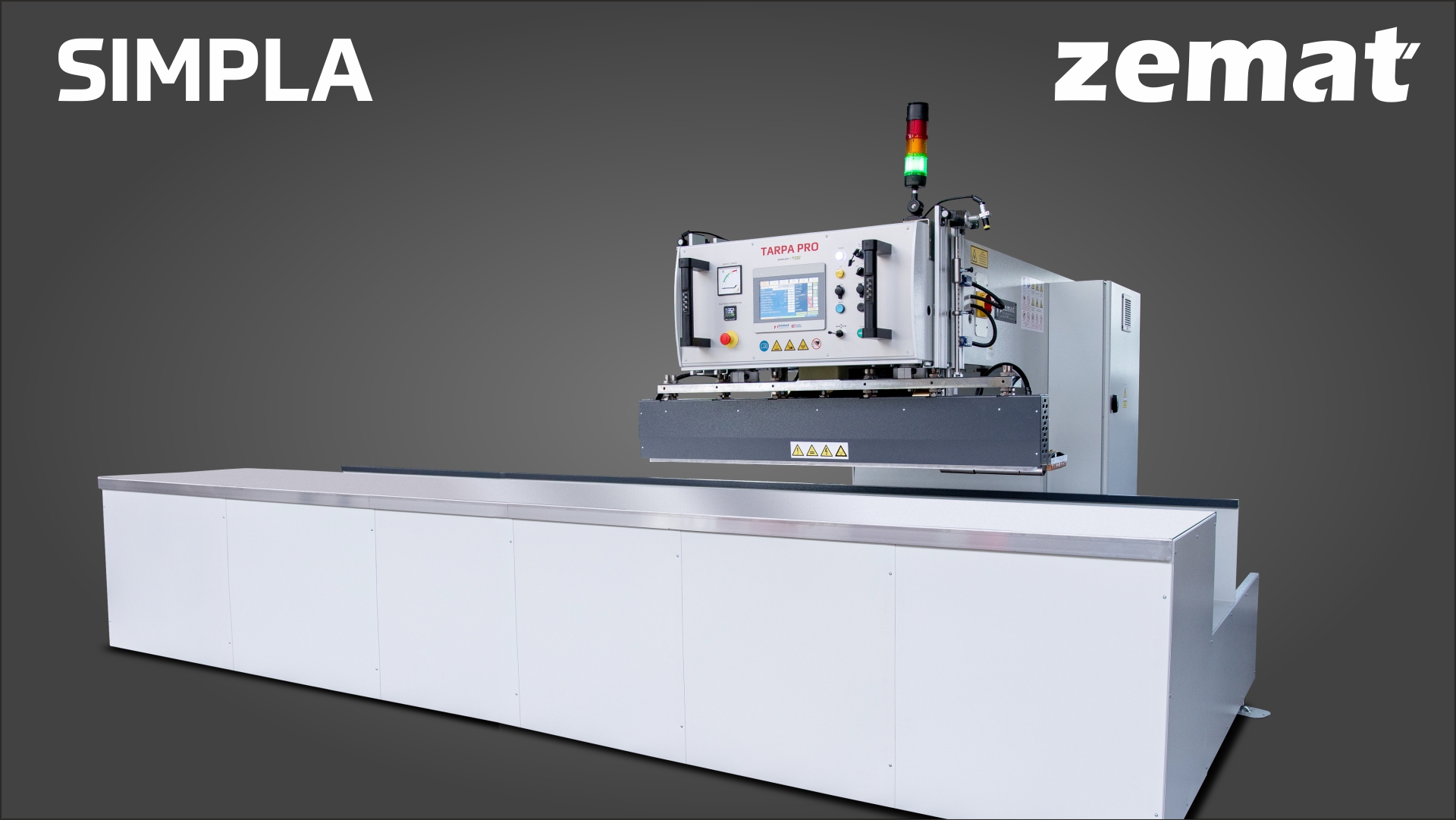

SIMPLA

Description

Universal high frequency welder SIMPLA allows to work with PVC, PU, TPU materials and can be equipped with special impulse electrode for welding non-HF weldable fabrics made of PE, PP and other non-bipolar materials. The machine can also be equipped with FlexEL™ ‘soft’ multilayer welding electrode or curved electrodes for sealing round window profiles made of clear PVC or any other shapes requiring precision welding. SIMPLA is equipped with special deep and wide trough behind the electrode for material storage and handling. The machine has optional smooth glide wheels for easy movement in-around welded fabric, or relocation to a desired place in the manufacturing hall. Full advanced programming functionality, including ATS™ autotuning and WCS™ systems, is achieved thanks to onboard PLC integrated with 10″ touch screen HMI on a swing arm for easy access to the welding area. SIMPLA machines have HF power output from 10 to 20 kW for heavier production loads and reinforced heavy duty fabrics, effectively providing between up to 800 cm2 of welded surface with one weld cycle.

Applications:

- Small and large format technical textiles PVC or PU coated

- Tensile structures, tents, shade systems, truck covers and side curtains

- Advertising signs and large format billboards

- Swimming pool liners and covers, flood dams and water tanks

- Airport hangars, portable storage structures

- Containment pools, oil booms, ground liners

Unique features:

- Magnetic, stainless steel, folding table

- Large space behind the electrode

- Electrodes up to 1200 mm

- Upper press plate for custom tooling

- Foot pedal operation

- Swing arm HMI

- Joystick to control the electrode

- Positioning laser guides

Features:

- Simple to setup and easy to operate

- Available standard models with 10 / 15 / 20 kW output power

- Sealing efficiency from 1 kW: up to 40 cm2 for standard PVC materials

- Universal usage for PVC, PU, TPU, reinforced technical textiles

- PE, PP, Polyester, Nylon weldability with optional Impulse electrode

- New generation Hi-Q Gen5 EcoHF stable and efficient HF generator

- Manual, semi-automatic and automatic operation

- ZTG ATS™ - autotuning HF power output system

- WCS™ Weld Check System - verifying quality of welds with preset parameters

- Easy material positioning with deep trough behind electrode

- Electrodes up to 1200 mm length

- Quick release system of the electrodes

- Built in LED electrode illumination

- Swing arm with 10" touch screen HMI panel (270° access to welding area)

- Built in VPN client and VNC server for remote diagnostics / software updates

- USB port for handling recipes