QUALITY & CONTROL SYSTEM (QCS)

Description

QUALITY & CONTROL SYSTEM (QCS) ARCHITECTURE & DESIGN

Scantech systems are manufactured with open architecture and modular equipements and can freely communicate with customer systems. Scantech modularity concept is based on the 3 main characteristics:

The equipment must be independent and self-sufficient: it fulfils the tasks it has been designed to perform.

The equipment modules can flexibly be assembled in the best configuration that suits the customer’s application.

The equipment itself is designed in a modular fashion

INDEPENDENCE AND SELF-SUFFICIENCY

Each device is equipped with its own intelligence: it minimizes external wiring.

The scanner’s function is to produce accurate measurements on its own: with correct physical units, useable by other equipements and by customer system.

The function of an operator interface is to drive a QCS system: it displays measurement data, accept commands, display status and reports: in no case, be involved in the manufacturing process or in the measurement computations.

The control system function is to compute set-points and to apply them.

ASSEMBLY OF THE MODULES

The Scanners, Control Systems, and User Interfaces can be assembled in any quantity for different network topologies.

EQUIPMENT MODULARITY

The equipements themselves are designed as an assembly of sub-modules to achieve a high level of standardization.

OPENNESS

Each device is equipped with configurable communication ports to support data exchange standards such as OPC UA.

These qualities provide Scantech customers with very important benefits:

Reliability: Is the result of the high level of standardization.

Ease of maintenance: In addition to component standardization, it is the result of the distribution of tasks.

Reduction of spare parts inventories: Is also the result of standardization

Scalability: Our approach allows easily the addition of new equipment to any initial configuration.

Long term sustainability: Is also a direct consequence of the modularity of the equipment.

Scantech offers three main types of equipment:

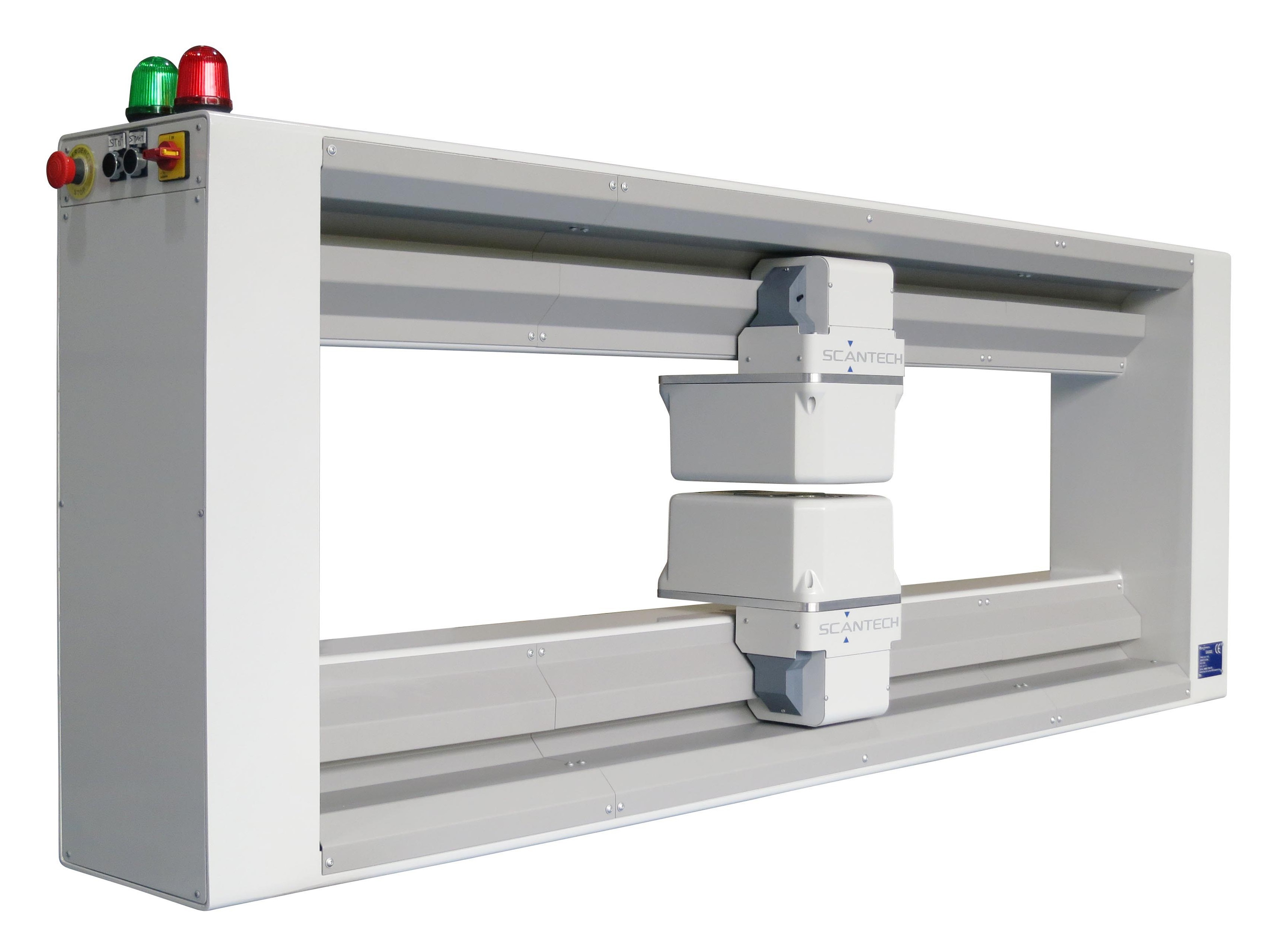

Scanners that provides the measurement data needed to control the manufacturing process and to determine the quality of produced materials.

Control Systems, whose function is to drive the manufacturing line: production parameters are measured within the customer defined tolerances of quality.

User Interfaces (for operators, production supervisor, maintenance team or quality manager…) drive the scanners and control systems(commands, parameters, status…) and display quality parameters in real time.

They also provide statistical processing, reporting, and archiving amongst a lot of other functions.

USER’S INTERFACE

FLEXSCAN, intuitive Scantech User’s Interface, help the operator to improve the production quality, reduce the scrap increase reactivity & productivity.

FLEXSCAN: A REAL ADDED-VALUE TO IMPROVE YOUR PROCESS

FLEXSCAN software allows:

Measurement data display

Measurement settings

Equipment status display

Equipment command

Embedded documentation

FLEXSCAN IS A DISTRIBUTED SOFTWARE

FLEXSCAN can be distributed on several computers at different places of a production line.

FLEXSCAN also handles:

Production orders

Production recipes

Data archiving and report creation (roll/production reports etc)

Different access levels are available:

Operator level: designed to be easy and user friendly. Access is limited to standard operating procedures

Production manager level: adds the possibility to change page layout and recipe information

Advanced or maintenance level: full access to all machine parameters and maintenance information

FLEXSCAN SUPPORTS ALL LANGAGES

One can change language on the fly passing for example from Chinese to German then to English while the system is running.

FLEXSCAN allows to display different kind of profiles:

– Standard profiles (individual scan profiles, composite profiles of rank “n”, exponential profile, roll average…)

– Standard trends, that represent the evolution in machine direction (roll trend, production trend)

– Macro-profiles (set of profiles on a specific zone of the web)

All charts offer the possibility to change scales, to centre the display on the target values or on the minimum and maximum values, to display all the statistics required.

With FLEXSCAN, the operator has also access to:

– alarms

– commands and settings

– recipes

– reports

Address

Scantech Germany GmbH

Rennweg 60

56626 Andernach

Germany

Telephone+49 2632 9589470

Fax+49 2632 9589479

Discover more from us