Thickness gauge for textiles, nonwovens, geomaterials, paper, floor coverings and leather

Thickness gauge for textiles, nonwovens, geomaterials, paper, floor coverings and leather

Description

Thickness gauge for textiles, nonwovens, geomaterials, paper, floor coverings and leather

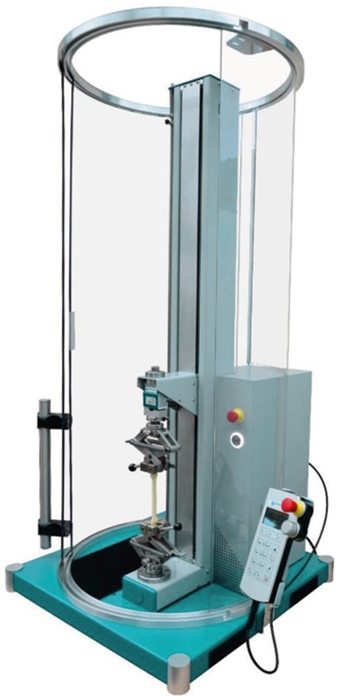

The HDM 2010 thickness gauge is a precise, easy-to-use and professional thickness gauge for determining the thickness of various materials. The most common test materials include textiles, nonwovens, geomaterials, paper, floor coverings, leather, foils and rubber. It is manufactured by us from a stable and robust housing with encapsulation against external influences.

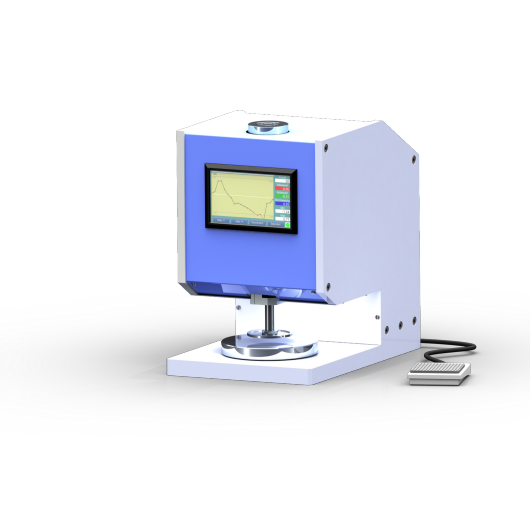

The DM 2010 thickness gauge is your choice if you value high measuring accuracy (up to 0.0001 mm), easy handling, fully automatic processing and objective, reproducible, non-manipulable results.

The thickness gauge can be used for different standards by using different measuring surfaces and load masses. The modular design means that customised specifications can also be implemented.

Adjustable parameters: Dwell time, opening height after the measuring process, minimum and maximum limits, number of measured values, unit (mm, inch), language (DE, ENG), colours and brightness of the display