Tensile compression testing machine up to 2.5KN

Tensile compression testing machine up to 2.5KN

Description

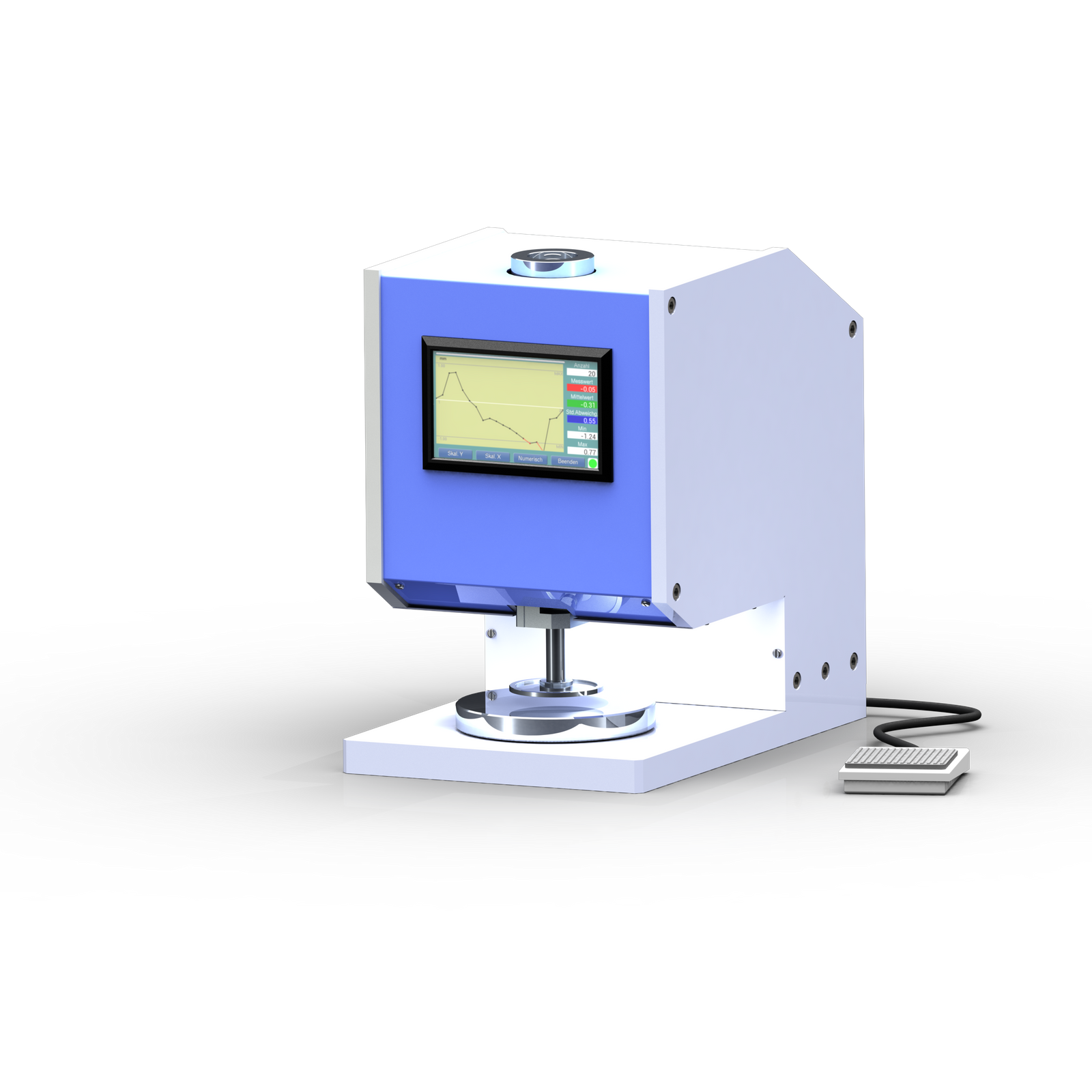

H2.5TMNI Tension and compression testing machine from 0.1N to 2.5KN

Richard Hess GmbH has developed the H 2.5 TMN universal testing machine with three different test chamber heights with a view to standardised material and component testing in the low-load range. As a cost-effective

low weight and high bending stiffness, the H 2.5 TMN is suitable for tensile, compression and bending tests on various materials.

bending tests on various materials. In combination with the ergonomic design and the new drive concept with stepper motors, safe and fast measurement with extremely simple operation is guaranteed both in harsh production environments and in sterile laboratories.

Key features

- Innovative brushless drive without gears

- Reduced noise pollution due to low motor speed and optimised frequency range

- Freely selectable control of crosshead travel, force and elongation

- High-precision force measurement using strain gauge force transducers

- Compact workstation design

- designed for both standing and seated work at the work table thanks to very flat lower crosshead and lateral arrangement of the electronics

- large machine base plate for mounting accessories and storing tools or samples

- Easy cleaning of the machine

Frame and test area height

The single-spindle universal testing machine H 2.5 TMN has a backlash-free ball screw in a C-frame design with spindle protection and an innovative brushless drive motor.

C-frame design with spindle protection and innovative brushless drive motor.

The newly developed testing machine is available in three different test area heights and can therefore be

optimally adapted to individual requirements.