Kuny AG

„Pultrusion“ und die Integration von RFID Chips in Pultrusionsprofile

Explore product

„Pultrusion“ und die Integration von RFID Chips in Pultrusionsprofile

Explore product

„Pultrusion“ und die Integration von RFID Chips in Pultrusionsprofile

Explore productAbout us

Die Firma Kuny AG gehört zu den führenden Herstellern von Textilbändern aller Art in Europa.

Im über 100 Jahre alten Unternehmen werden Bänder für die verschiedensten Anwendungsbereiche produziert: Kurzwaren, Textilindustrie, Geschenkverpackungen, Floristik, Hobby, Basteln, Orthopädie, Medizinalprodukte und Bänder für technische Anwendungen.

In Küttigen/Schweiz wird eine vollstufige Produktion betrieben (Weben, Färben, Ausrüsten, Drucken, Konfektionieren). Dadurch kann jederzeit schnell und flexibel auf die Wünsche der Kunden eingegangen werden. Die Qualität und der kundenorientierte Service übertreffen die Erwartungen unserer Kunden.

Weberei

Im Werk Küttigen stehen rund 160 Bandwebmaschinen im Einsatz, welche laufend den neusten Technologien angepasst werden. Auf einem Grossteil der Maschinen werden Rohbänder wie Samt, Doppelsatin und Rips produziert.

Veredelung

Die gewobenen Bänder werden anschliessend in den gewünschten Farben eingefärbt. Je nach Echtheitsansprüchen können unterschiedliche Prozesse und Applikationsverfahren eingesetzt werden. In der modernen Druckerei besteht eine Vielzahl von Applikationsmöglichkeiten. Mittels Flächen-, Folien-, Präge- oder Thermotransferdruck können nahezu alle Kundenwünsche erfüllt werden. Zusätzlich stehen Einrichtungen für chemische Appreturen und Beschichtungen zur Verfügung.

Lager

Um die Erwartungen der Kunden nach promptem Lieferservice zu erfüllen, werden hohe Lagerbestände an Halbfabrikaten und verkaufsfertig aufgemachten Bändern geführt.

Our product groups

- Technology and Processes

Keywords

- Klettverschlüsse, Hook and Loop Fastener

- Technische Bänder, Fastening Systems

- RFID (RADIO-FREQUENCY IDENTIFICATION)

- Hakofix® Camouflage

- FR flammhemmend, FR flame retardant

Our Products

Camouflage

KUNY AG ist noch einen Schritt weiter gegangen und hat die Camouflage-Technologie eingeführt. Diese Technologie ermöglicht es uns, Hakofix®-Produkte mit Camouflage-Mustern, je nach Kundenwunsch und gewünschten LAB- und IR-Werten, zu bedrucken.

„Pultrusion“ und die Integration von RFID Chips in Pultrusionsprofile

Entwicklung von pultrudierten strukturellen Komponenten für den Einsatz im Nutzfahrzeugbereich

Einsatz von integrierten UHF RFID-Bänder:

- Kompatibel und flexibel einbaubare RFID-Band für das hochautomatisiertes Verfahren zur Herstellung von faserverstärkten Kunststoffen

- Geeignet für das kontinuierliches Pultrusions-Verfahren

- Ermöglicht die Auslesung / Digitalisierung von Bauteilen mittels UHF Reader

Verwendete Materialien:

Fasern:

Überwiegend Glas oder Carbonfasern in Form von Rovings, Textilien oder textilen Halbzeugen

Matrix:

Polyester, Vinylester, Epoxid oder Phenolharze

Mögliche Anwendung:

Integration von RFID Chips in Strukturbauteile zu Rückverfolgungszwecken (bspw. um Rückschlüsse

auf Produktionscharge und parameter bei Problemen wie beispielsweise frühzeitigem Bauteilversagen)

Haftverschlüsse (Hakofix und Fixvelours)

Unsere Haftverschlüsse erfüllen höchste Qualitätsansprüche.

Zusätzliche verfügbare Ausrüstungen:

- reaktivierbarer Klebestoff

- Heissschmelzkleber

- kaschiert mit Doppelklebeband

- Verfügbare Breiten: 16mm, 20mm, 25mm, 30mm, 38mm, 50mm, 100mm

- Farben gemäss Farbkarte Hakofix

- Gewobene Bänder mit Webkanten

- Abschälfestigkeit 1 x Schliessen und Öffnen mind. 1.30 N / cm Bandbreite

- 10’000 x Schliessen und Öffnen mind. 0.65 N / cm Bandbreite

- Längsscherfestigkeit 1 x Schliessen und Öffnen mind. 6.0 N / cm2

- 10’000 x Schliessen und Öffnen mind. 4.0 N / cm2

Klettverschlüsse (FR flammhemmend)

Der erste permanente inhärente flammhemmende Haftverschluss aus Polyamid 66.

Für mehr Funktionalität

- ausgezeichneter Tragkomfort

- hervorragende Funktionalitätseigenschaften

- lässt sich bestens im Verbund verarbeiten auch mit Aramidgeweben

- gute Waschbarkeit ohne Verlust der flammhemmenden Wirkung

- keine Entfachung der Zündquelle

- keine Flammenausbreitung (schützt den Träger und hält die Schutzbekleidung intakt)

- keine zusätzliche Gefährdung des Trägers bei Flammenkontakt

- keine Verletzungsgefahr durch brennendes oder abtropfendes Material

Anwendungsbereiche

- Schutzbekleidung Feuerwehr

- Schutzbekleidung Polizei

- Ballistische Schutzweste

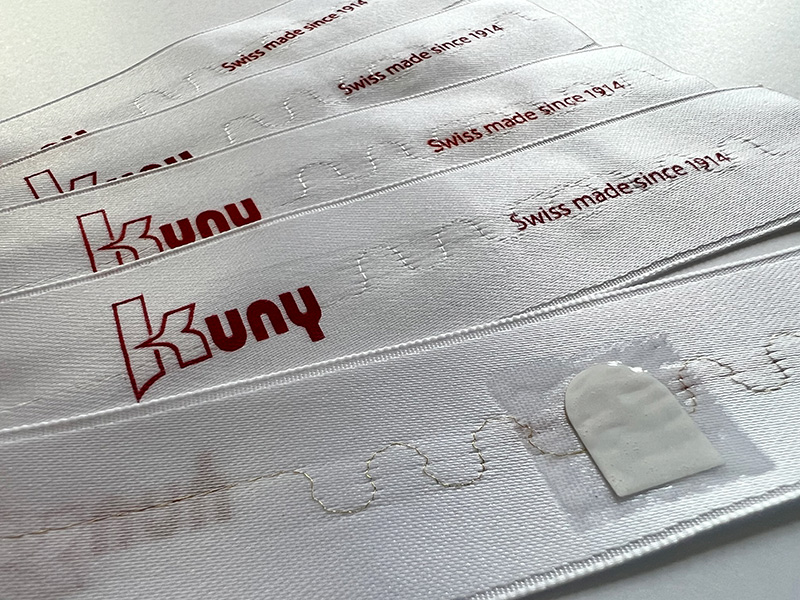

RFID (RADIO-FREQUENCY IDENTIFICATION) Label

Mit unserer neuesten Entwicklung verbinden wir die einzigartige RFID-Technologie mit dem hochwertigen Tragekomfort eines Satinbandes.

Die eingearbeitete Antenne in Kombination mit einem RFID-Chip ermöglichen die Vernetzung von textilen Materialien mit dem Internet of Things (IoT).

Produktspezifikation / USP

- Volle Transparenz und Überwachung der Lieferkette

- Erhöhter Markenschutz

- Warenbestandsführung in Echtzeit

- Unsichtbarer Diebstahlschutz

- Ersatz von Hangtags und höheren Identifikationsgrad

- Artikelauszeichnung, -erkennung und Datenaustausch auf Distanz

- Kompatibel mit bestehenden Druck- und Codierungssystemen

- Geeignet für den Einsatz von Wäscheartikeln