The exhibitors & products at Techtextil 2026 will be available here from mid-January 2026.

21705 Fencing fabric

21705 Fencing fabric

Description

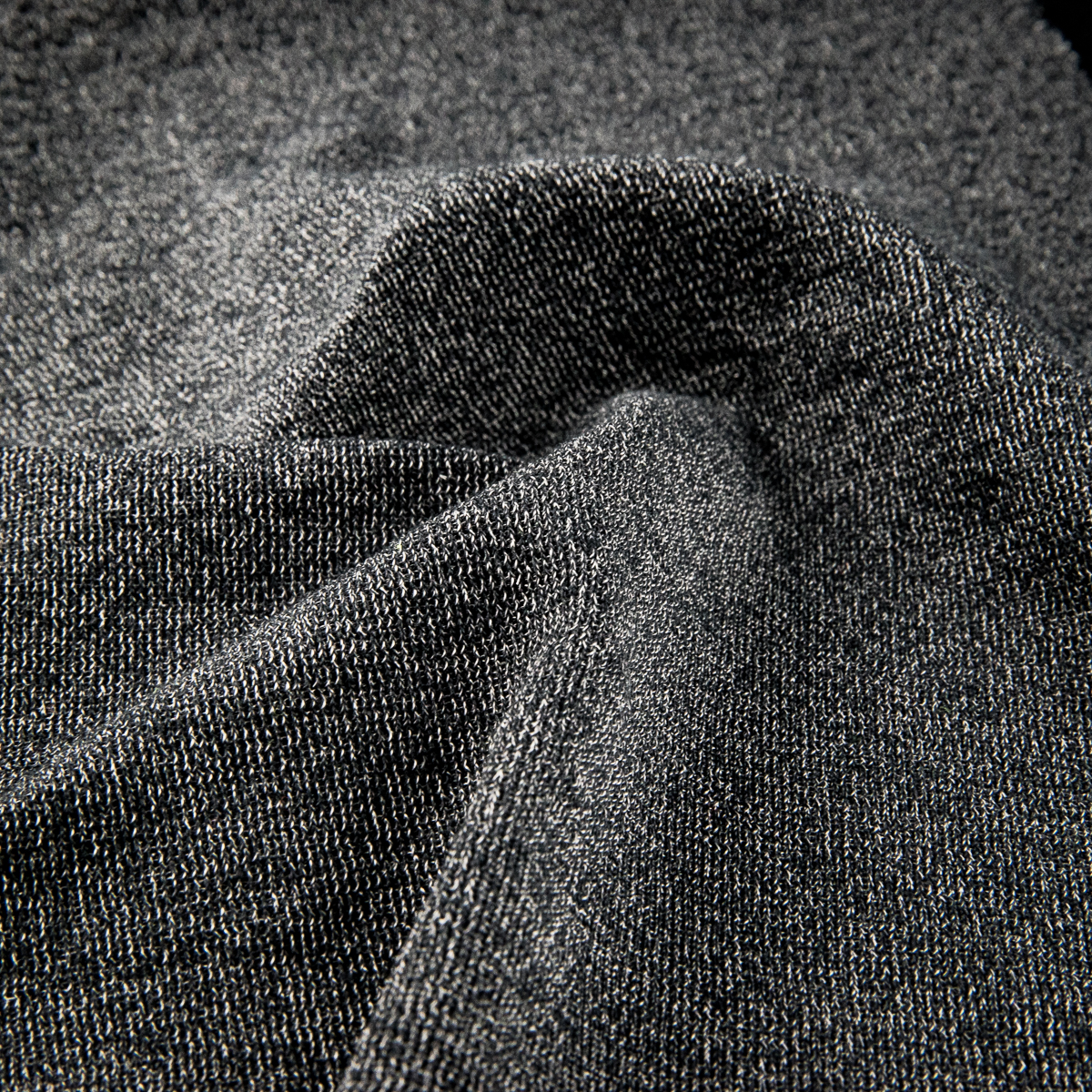

Our Fabric 21705 sets new standards in terms of puncture resistance, cut protection, and wearing comfort. This knitted fabric, primarily composed of Dyneema is especially suitable for fencing suits and gloves. With an impressive puncture resistance of >800N, this fabric provides excellent protection in demanding situations.

The combination of Dyneema, polyester, and elastane not only gives Fabric 21705 exceptional elasticity but also provides high cut protection. The wearer benefits from flexible freedom of movement, ensuring remarkable wearing comfort.

It's no coincidence that our Fabric 21705 is preferred by Olympic champions as material for fencing gloves. Its outstanding properties make it the top choice for athletes who prioritize both peak performance and protection.