Fiberflon A.S.

Fiberflon A.S.

Velimese OSB 207. Sokak No: 2/1, Ergene

59930 Tekirdag

Türkiye

Telephone+90 282 676 42 08

Fax+90 282 676 41 98

About us

FIBERFLON is a leading manufacturer and preferred supplier of PTFE and silicone coated fabrics, pressure sensitive tapes, and belting products that are used in diverse manufacturing applications. Our distinct line of products resolve industrial demand for resilient, yet pliant engineered materials that exceed expectations in rigorous environments. FIBERFLON® is committed to provide its customers with high-quality products, excellent customer service, constant technical innovation and engineering experience.

Since 1988, FIBERFLON has been actively engaged in finishing and coating of advanced fabrics like Glass, Kevlar®, Nomex® with fluoropolymers. We offer our services through our own offices and via a strong network of experienced distributors established in more than 60 countries.

FIBERFLON is the critical component representing a wide spectrum of effective industry applications such as heat-sealing in Packaging, curing and drying in Textiles, rubber extrusions in Automotive, coated release sheets in Flooring, and conveyor belting in Food Processing; and many more.

FIBERFLON offer a variety of products to meet the specific demands of the Textile industry. We offer the following products for drying, curing, garment fusing and thermal bonding of fabrics and nonwovens, for laminating and curing of composites, flooring and textiles, for architectural needs:

- PTFE open mesh belts

- PTFE process belts

- PTFE multiply endless belts

- PTFE coated/laminated materials for fabric expansion joints

- PTFE architectural fabrics

Keywords

- multiply endless belts

- Fiberflon

- open mesh belts

- PTFE process belts

- PTFE coated glass fabrics

Our Products

PTFE Coated Glass Fabrics

No other plastics material can match PTFE's unique combination of properties. When joined with the durability of woven glass fibers; the resulting union of Fiberglass and PTFE make for an indispensable production resource. The high-temperature resistance and non-stick surface properties of PTFE/Glass Coated Fabrics are ideal strongholds for optimizing work flows in rigorous industrial settings.

- Outstanding temperature resistance(from -170°C to+260°C)

- Excellent chemical resistance

- Superior non-stick surface, easy to clean

- High dielectric strength

- Dimensional stability

- Resistance to UV, IR and HF

- Non-toxic

PTFE-Glass Fabrics and Tapes with Pressure Sensitive Adhesives

PTFE -Glass Fabrics with pressure sensitive adhesives provides an excellent release surface for a diversity of industrial applications requiring high temperature, electrical resistance, mechanical strength, fire retardancy and cost effectiveness.

These products are produced with either silicone or acrylic pressure sensitive adhesives. The silicone adhesive coated products have a continuous operating temperature range between -70°C and +260°C while the acrylic adhesive coated products provides high initial tack, enhanced solvent resistance and a continuous service temperature range of -40°C to +170°C.

Fiberflon® silicone PSA products can be supplied as log rolls or slitted tapes. Self-wound (without liner) tapes are available as well. Some applications : Easy release surface on heat sealing and packaging machines, ironing and pressing equipment, covering drying cylinders, lining chutes, release surface on bonding tools.

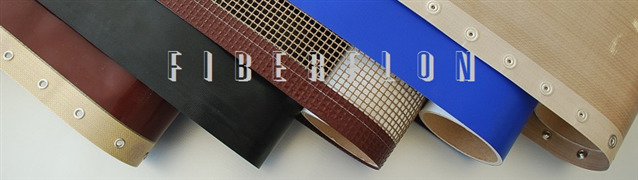

PTFE Open Mesh Belts, Process Belts & Multiply Endless Belts

FIBERFLON offers a variety of PTFE coated and laminated belting materials. At FIBERFLON we understand the crucial nature of conveyor systems as the nerve center of operations. For drying, curing, thermal bonding of fabrics and non wovens we offer our PTFE open mesh belts. For laminating, curing of composites flooring and textiles we offer our PTFE process belts or multiply endless belts. So we partner with our clients in selecting the best belt to ensure all elements of the production cycle.

- Food and Drug Administration (FDA) compliancy regulation approved for use in food contact processing and packaging (21 CFR 177.1550).

- Dimensionally stable from -99.4° to 500°F (-73° to 260°C).

- Exceptionally durable to stave off oils and grease penetration.

- Non-toxic, tasteless, odorless.

- Extremely low elongation (<1%).

PTFE Architectural Fabrics

FIBERFLON® architectural fabrics are made of PTFE coated glass fabrics. The fuoropolymer PTFE is the most durable fabric coating available. The PTFE is applied equally to both sides of the glass fabric. This encapsulates the glass fibers and protects them from potential degradation due to moisture influx.

- Outstanding temperature resistance (from -170ºC to +260ºC)

- Resistant to corrosive agents

- Low thermal mass

- Controlled porosity

- Superior non-stick surface, easy to clean

- non-combustible up to DIN 4102 B1-A2

- Dimensional stability

- Resistance to UV, IR and HF

- Non-toxic

- Superior tracking

PTFE Coated/Laminated Materials for Fabric Expansion Joints

PTFE coated and laminated composite materials, produced by FIBERFLON, are widely used for manufacturing of Non-Metallic Expansion Joints, Insulation Jacketing and Floating Roof Seals for oil storage tanks.Our PTFE/fiberglass composites and laminates are engineered to survive the corrosive environments and severe temperatures.

High quality woven fiberglass fabrics coated with a specially formulated fluoropolymer coating designed to provide enhanced flex properties and excellent high temperature performance, and then laminated with PTFE(Teflon) multilayer cast films to provide superior gas barrier properties.

Flexible PTFE coated fabrics for excellent temperature,fire andchemical resistance, release, and weatherability properties for non-metallic expansion joints.