Datatex Consulting Srl

Address

Datatex Consulting Srl

Viale Lunigiana 46

20125 Milano Milano

Italy

Discover more from us

Follow us on

About us

Datatex is the world’s leading supplier of IT software solutions for the global Textile and Apparel Industry with the largest install base of textile software, and customers in 45 countries and 5 continents.

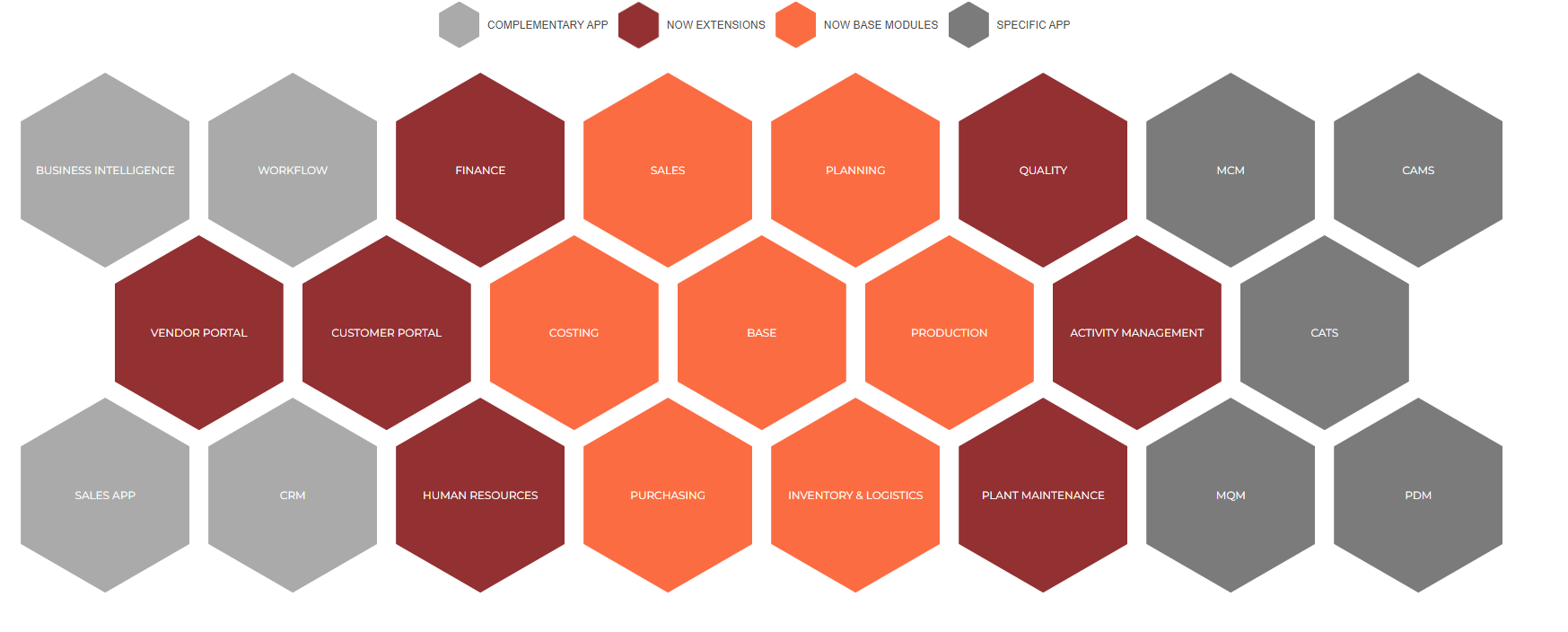

Datatex software is called NOW (Network Oriented World). It is a family of management software composed of innovative functions and modules developed to help textile and fashion companies, regardless of their size. A solution capable of meeting the new demands of the sector such as a wide variety of products, short delivery times and lower costs. Datatex NOW ERP is characterized by great flexibility, able to adapt to every aspect of the business processes.

Our product groups

- Research, Development, Education, Consulting

Our application areas / Solutions

Downloads

Keywords

- erp textile

- mes

- cloud solution

- fashion sofware

- datatex

Our Products

NOW - Network Oriented World

NOW is a family of management software composed of innovative functions and modules developed to help textile and fashion companies, regardless of their size. A solution capable of meeting the new demands of the sector such as a wide variety of products, short delivery times and lower costs. Datatex NOW ERP is characterized by great flexibility, able to adapt to every aspect of the business processes.

PLANNING MODULE

Every company must be well organized to make their operations run smoothly. For this reason, it is fundamental to plan everything from the beginning to avoid being surprised by drawbacks. It is important, in addition to planning, to predict the consequences, both positive and negative of our programming choices. When we talk about prediction, we intend to conduct some actions… such as trend management, reviews for customer, agent, market, season/collection and period. The prediction for complete/partial product code or per family product, the different levels of prediction (style and style-color) and many more…

PDM

Product Lifecycle Management is a strategic approach, based on technologies, specific organization methodologies and historical experience, to managing the evolution of a product from conception to it being discontinued. It is fundamental for companies to have a deep knowledge of their own product. PDM is a software that collects and organizes documents or data related to the entire product life cycle: concept, design, production and obsolescence. The PDM is specifically designed for textile and apparel companies and its flexibility allows an easy integration and exchange of data with CAD and ERP systems. Some of PDM main features can fulfill many business activities’ requirements, linking users with different tasks and responsibilities, allowing the interface with account managers and related software, and integration with the ERP company to manage the entire Product Lifecycle (PLM).

MOBILE SALES APP

Mobile Sales App is a mobile solution dedicated to the collection of order and attempted sales through tablets Androis and IOS, allowing both customer and management to save time. This application provides any kind of information, from the most important, such as multimedia catalogues, and information about customers, to the simplest with speed and simplicity. The Sales App can be used offline too, as you can collect your orders and consult the products in whatever place you are. As soon as you can connect to a network, you just need to synchronize your device with the NOW ERP. A further development is the large capacity of the Database, which contains a lot of information such as the customer cards, a view of all articles, a catalogue of products, product and customer statistics, among other definable information.

MCM - MQM MODULE

MCM

MCM is a graphical capacity planning tool to coordinate and plan production in a better way and to provide tailored suggestions to the customer. It has to handle management and timing of the production process by verifying:

Machinery capacity

Materials availability, both in the warehouse and to the suppliers

Additional resources

Prefixed deadlines

MCM helps the company to solve many issues and analyzes bottlenecks. The main strength is the definition of a complete insight over all departments and a real integration with the system Datatex ERP TIM/NOW. In MCM all production requests, either coming from the ERP or entered manually, are prioritized and then placed on the Gantt. This can be done in either a finite capacity evaluation or an infinite capacity evaluation. Using finite capacity planning the system loads capacity based on a first-come, first-served approach and calculating the delivery date. Infinite capacity planning loads capacity based on requested delivery date and highlights the over-capacity bottlenecks and the planner determines the priority and delivery dates.

MQM

Either after capacity planning has occurred or as a step of capacity planning itself, the planning department must schedule production on a resource, either human or machine. The MQM module provides a graphical Gantt chart with user defined rules to make the scheduling process more accurate and more efficient, providing better results in less time.

MQM considers the planned start and end date of every step and presents this planning window to the scheduler, with machines color-coded to indicate best fit and also previously scheduled jobs color-coded to indicate opportunities to reduce setup time. The system dynamically calculates the setup time based on the sequence of product steps and characteristics of the products.

In addition to production resources, capacity, and date, the MQM system consider other constraints. The system can be configured to check material availability dates when scheduling, check future or subsequent production areas to ensure any overlap is within configured allowances, check non-capacity constraints such as tools or staffing levels to ensure the schedule is executable, and also consider the schedule dates of other products on the same order to ensure they complete within an acceptable amount of time of each other, among other considerations.

MQM also has an automatic sequencing capability. The schedule defines the rules, using heuristics to balance on-time delivery, setup cost implications and reduction of WIP. The system will automatically schedule all production that the rules allow and can be run in multiple iterations with loosening restrictions, if needed. Ultimately the remaining few production steps can be manually put on the Gantt chart by the scheduler.

When MQM is integrated to the ERP or shop floor data collection systems (manual or automatic), the schedule will be updated to reflect the reality of the production recording. This will alert the scheduler to jobs running late and the impact on subsequent jobs in the schedule, or the opportunity of moving production ahead due to more efficient processing.