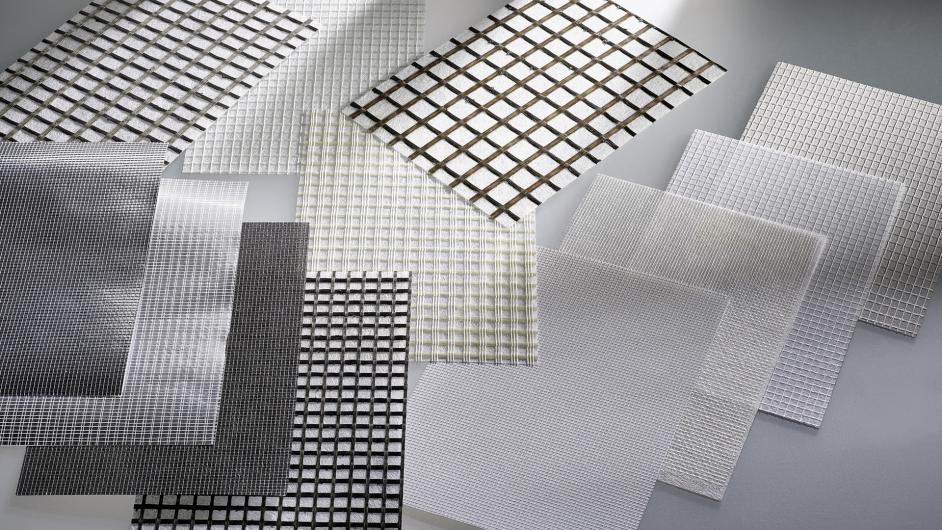

Description

Laminates combine the superior technical properties of different products. Lamination with a woven fabric, for example, significantly increases the perforation and puncture resistance, which is usually only achieved with tightly woven fabrics or heavy-duty polyester fleece materials.Due to their clean and closed surfaces, laminates always offer a high-quality appearance.Non-combustible laminate designs are also available on request.

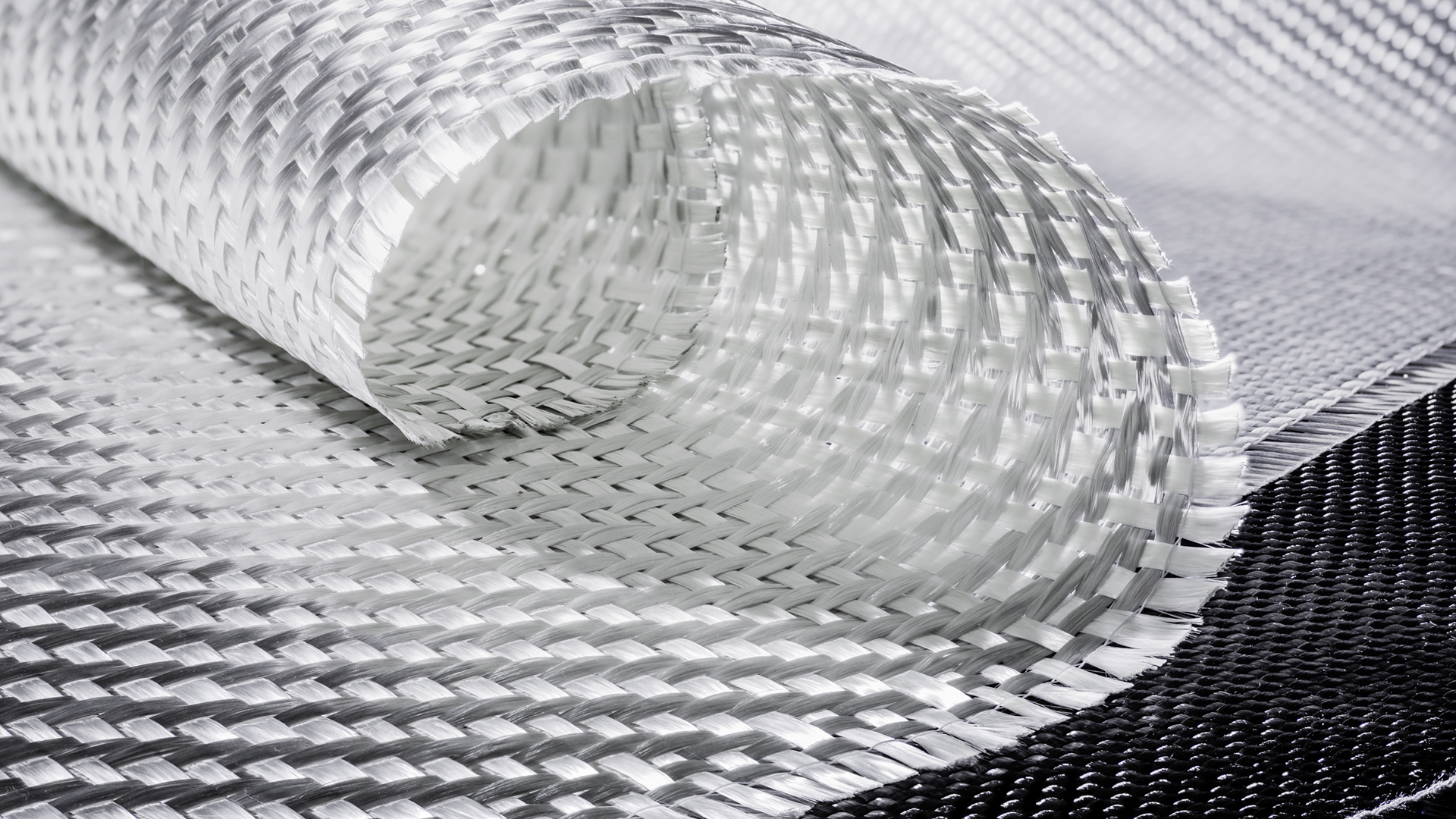

Woven fabric/fleece

Laminates based on open mesh fabrics woven from glass or polyester fibers and combined with glass fiber fleece are used, for example, in acoustic panels and for coating roofing and waterproofing membranes.

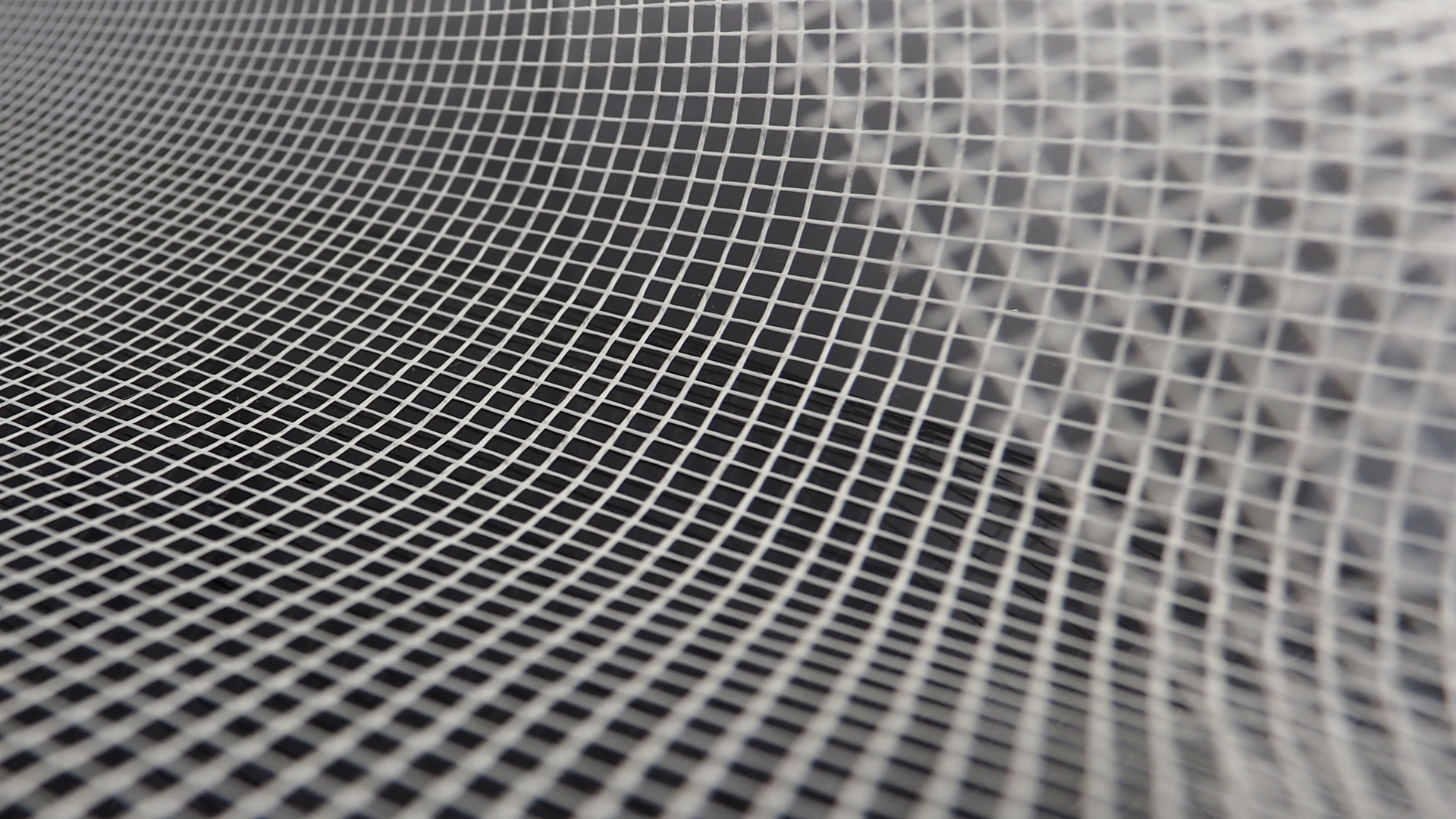

Woven mesh fabric/woven mesh fabric

Laminates consisting of two different woven open mesh fabrics are used as drainage and de-watering fabrics due to their adaptable permeability.

Knitted fabric/fleece

Laminates based on open mesh fabrics knitted from glass or polyester fibers not only excel in flatness, uniform fabric appearance and low thickness; depending on the fiber material used, the knitted fabric exhibits a number of advantageous properties:

- When combined with a knitted polyester fabric, the laminate demonstrates good elasticity, which allows the material to adapt optimally to the forces acting on it and thus be used, for example, in roofing and waterproofing membranes.

- In combination with a knitted glass fiber fabric, the tear and tensile strength of the laminate is significantly increased, making it ideal for use with insulation materials such as rock or glass wool.