Benzler Antriebstechnik GmbH

EON 2

Explore product

EON 2

Explore product

EON 2

Explore productAddress

Benzler Antriebstechnik GmbH

Erna-Scheffler-Str. 2

40476 Düsseldorf

Germany

Telephone+49 800 3504000

Discover more from us

Follow us on

About us

Elecon Engineering Company Ltd. was established in the year 1951 as The Pioneers in the manufacturing of Industrial Geared motors and Reducers, Material Handling Equipment, Mining equipment, casting processes etc. Elecon is one of the largest manufacturers of Industrial Gears in Asia and Material Handling Equipments.

The expertise in the successful production of custom gearboxes for steel mills, high-speed turbines, naval aircraft carriers, and many growth sector industries is increased by Elecon's acquisition of Benzlers- Radicon Group from David Brown Gear Systems in 2010.

Benzler & Co was founded in 1944, thereby creating the foundation of the Benzlers Company. Initially, Benzlers was a trading company that serviced the market with complete drives such as roller chains, v-belts etc. The company expanded rapidly, and branches were opened in several places in Sweden already in the early years.

At the end of the 50s, the first production of gears was established. The Sala gear was born and the success that this gear achieved brought Benzlers to other markets, outside of Sweden. Export to several European countries was started. This was a significant turning point for Benzlers, which could now take its place among the leading European manufacturers, and became known as the leading Nordic brand for gears, gear motors and industrial gearboxess.

During the 90s and 00s, Benzlers continued to grow, and the company built up representation in 14 countries.

A unit of Elecon Engineering Company Ltd. which is also the 3rd largest Material Handling solutions company in the country along with in-house design, manufacturing, fabrication, component manufacturing, and support system in a Vertically Integrated Model.

First in India to manufacture sophisticated equipment for bulk Material Handling and a product range that caters to almost every Industrial sector in India.

The product solutions include designing, manufacturing, supply, erection and commissioning of our products.

Our product groups

- Drive systems and components

Keywords

- Power Transmission

- Gearbox

- Europe

- Elecon Benzlers

- EON 2 SEIRES

Our Products

GEARED MOTORS

Geared motors and gearboxes are the heart of any engineering product. It is not just the torque and speed but the RELIABILITY of the Geared Motors that defines the performance of your product or equipment. So, whenever you think of Geared Motors, choose Reliability over the ordinary.Choose RADICON POWERBUILD, a name that personifies RELIABILITY and VALUE.

We have follwing Product Portfolio:

1. SERIES M - HELICAL INLINE GEARED MOTOR

2. SERIES C - RIGHT ANGLED HELICAL WORM GEARED MOTOR

3. SERIES F - PARALLEL SHAFT MOUNTED GEARED MOTOR

4. SERIES K - RIGHT ANGLED HELICAL BEVEL GEARED MOTOR

5. SERIES PL - PLANETARY GEARED MOTOR

6. ROLOID GEAR PUMP

Planetary Gearbox

Planetary gearboxes have much higher mechanical rating compared to parallel shaft gearboxes as the power being transmitted gets equally distributed among four streams in each stage thus reducing the induced stresses, which very much optimizes the sizes as well allows to accommodate higher ratio to eliminate open pair.

• The reduction in floor space as compared to conventional drive i.e. with open gearing, almost to the

tone of 50% reduction in floor space.

• Heaviest gear internals such as annuli are stationary thus requires no bearing and automatically

improves the stability and reduces the vibration level and in turn noise. Low noise level 80-85 db as

well as low vibration level going up to 4.5 mm/sec can be achieved.

• Planetary gearbox has an advantage the planet bearings are only loaded where as in case of bearing supporting sun or carrier loads are more or less nullified by virtue of higher number of planets and their equal and opposite forces.

• Lubrication of planetary gearbox is quiet simple as the rotating gear train partially acts as pump thus

allowing splash lubrication.

• We are proposing two to four stage planetary gearboxes; in each stage sun is input and carrier is the output keeping annuli stationary as well acting as casing.

• Elecon Benzler’s machine capability cuts the internal teeth of annulus to the accuracy of DIN-7 or Grinds if required to the accuracy class DIN-6.

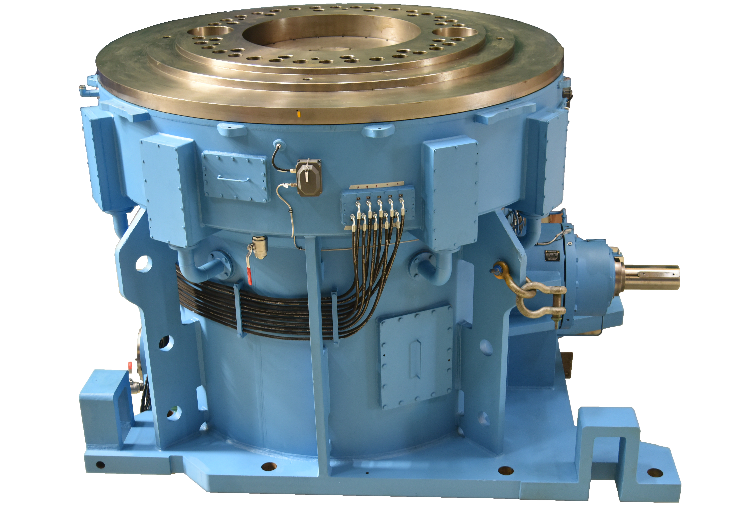

BEVEL PLANETARY GEAR UNITS VERTICAL ROLLER MILLS

Roller Mils are directly driven bevel-wheel planetary gears or bevel cylindrical gear units.

The gear unit represents an almost integral component of the mill. The output flange of the gear unit is rigidly connected with the grinding table. In addition to transmitting the torque ,the gear unit also has capability to take up the reaction forces from the the griding force of the mill’s rollers.

Hydro dynamically or hydrostatically lubricated thrust bearing being mounted in the upper housing parts of the gear unit absorb the grinding force which is then transferred though the housing into mill’s foundation .

This growing number of roller mills in operation as well as the increasing specific need and demand of gear transmission feature .

Features: Bevel Planetary Gear box with horizontal input and vertically flanged output shaft with inbuilt thrust bearings

Advantages: Compact design suitable for high power transmission and capable of withstanding high loads due to grinding rollers

Technical Specifications: B2PV 101 to B2PV 186

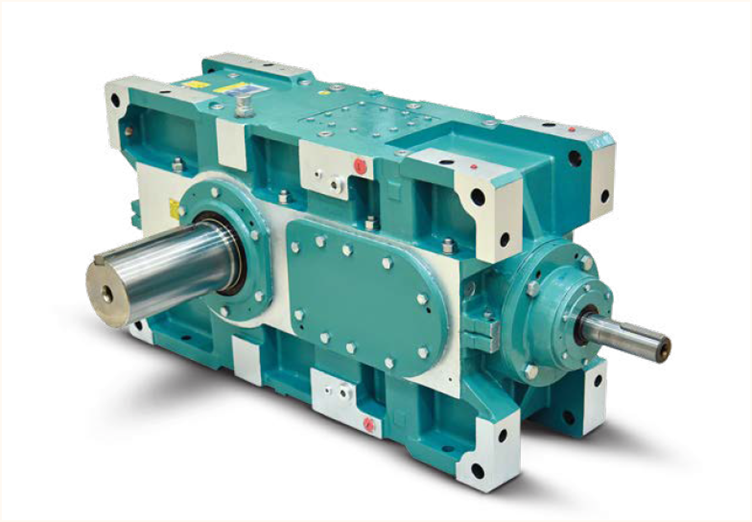

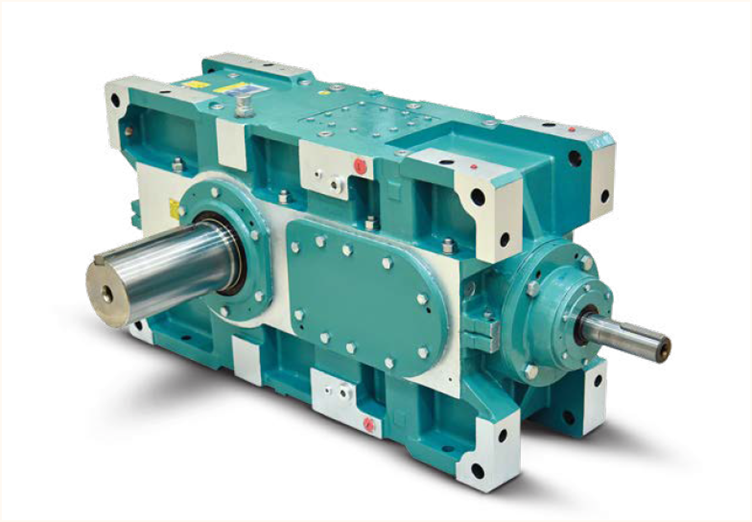

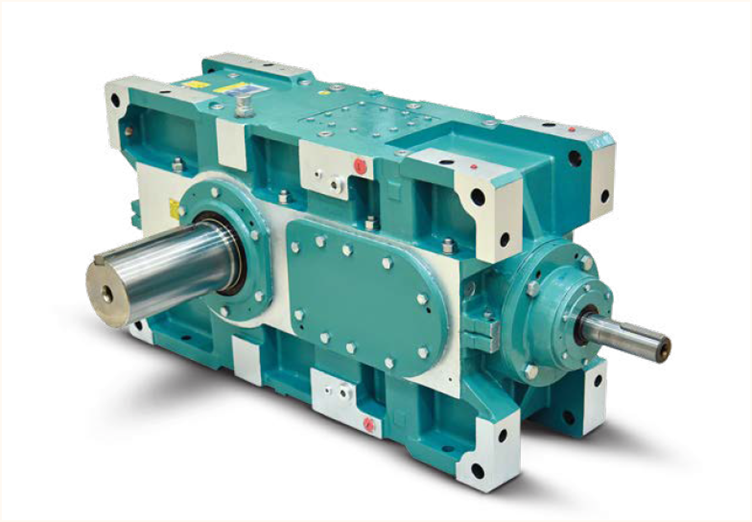

EON 2

Discover the next level of performance with the ELECON BENZLERS Second Generation Gearbox - EON2 series. Engineered to perfection, this series offers a versatile range of Helical and Bevel-Helical executions tailored to meet a diverse spectrum of applications.

The EON2 series represents the culmination of over seven decades of relentless research and

development by ELECON BENZLERS. Our journey has been shaped by invaluable field experience

spanning a multitude of industries and applications.

Benefits with EON2 Gearbox:

• Compact dimensions

• Robust highly reliable design

• Fully modular design

• High torque to weight

• Prompt delivery

• Boost efficiency

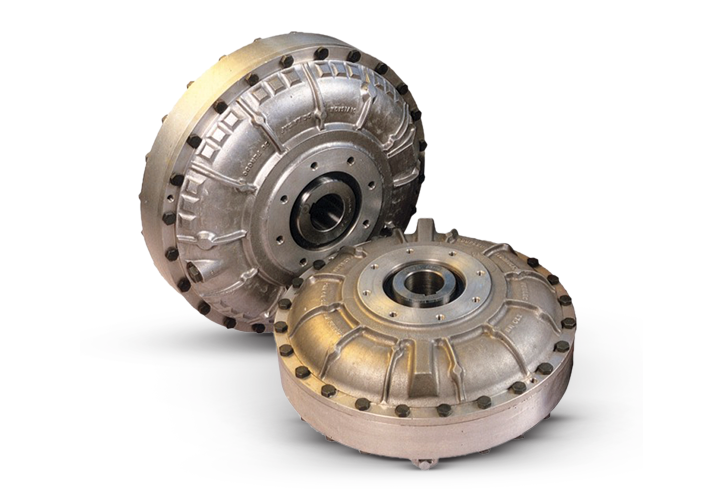

Couplings

Elecon Benzler is a leading manufacturer and exporter of various types of fixed and variable speed industrial couplings. Elecon Benlzer’s range of Couplings includes Elign Geared coupling, Elflex Flexible couplings, Fluid couplings, Scoop controlled variable speed controlled fluid coupling, and torsion shaft couplings. Elecon Benzler couplings are well known for their energy efficiency with low maintenance there by increasing the life of gearboxes and motors that drive them.

Elecon Benzler couplings are preferred by the engineering industry due to their rugged construction, simple design, and operational reliably in extended duty cycles and are widely used in multiple industries including steel, rolling mills, heavy engineering, sugar, material handling, mining, coal, power, and more.

SPECIFICATION RANGE

Size: 130 to 6,27,000

Power: 0.136 to 2,320 kW

Torque: 0.70 to 6,2070 KNm