Trützschler Group SE

Discover more from us

About us

The Trützschler Group SE is a German textile machinery manufacturer headquartered in Mönchengladbach, Germany. The company is divided into four business units: Spinning, Nonwovens, Man-Made Fibers, and Card Clothing. Trützschler machines, installations and accessories are produced and developed in ten locations worldwide. This includes four factories in Germany (Dülmen, Egelsbach, Mönchengladbach, Neubulach), as well as sites in China (Jiaxing and Shanghai), India (Ahmedabad), the USA (Charlotte), Brazil (Curitiba) and Switzerland (Winterthur). Service companies in Türkiye, Mexico, Uzbekistan and Vietnam and service centers in Pakistan, Bangladesh and Indonesia provide customer proximity in key regions for the textile processing industry.

Trützschler is able to provide a complete line-up of technologically leading machinery that is specifically developed for rotor and ring yarns from recycled materials.

Thanks to our partnership with Balkan Textile Machinery.INC.CO, we are closing the loop and supporting a circular economy by becoming the first full-liner in spinning preparation for recycling. Balkan's machines help to cut, mix and tear textile waste into fiber tufts that are then pressed into bales of secondary fibers which can be fed into the preparation process with Trützschler machines. Customers benefit from combined, perfectly finetuned, reliable and reproducible processes.

Our product groups

- Technology and Processes

- Fibres and Yarns

Our application areas / Solutions

Keywords

- truecycled

- sustainability

- yarns

- spinning

- recycling

Our Products

Blowroom lines for recycling textile waste

Optimum opening, cleaning & blending of secondary fibers

The technological challenges in the processing of secondary fibers from shredded textile waste are considerable: All particles of yarn and woven fabric must be opened reliably or separated off. Truetzschler blowroom lines for recycling feature flexible setting options and intelligent processes, facilitating perfect opening, cleaning and blending of synthetic and cotton secondary fibers. They also prevent unnecessary waste or new short fibers from being produced.

Tearing lines

Structure of a tearing line

The first step is the cutting of the textile hard waste. The starting material is cut into small pieces of fabric by two guillotine cutters. In a box room, the material is homogenized and stored in batches. The material is then evenly fed into the tearing machine via the feeding unit. The material is disintegrated into fiber tufts via six cylinders that are equipped with needle bars. The fiber tufts are finally sucked off after the tearing machine and pressed in a bale press.

The intelligent Card TC 30Ri for recycling

Utilizing textile waste intelligently

Spinning straw into gold? That's only possible in fairy tales. However, using textile waste to create new values is now reality: The intelligent Card TC 30Ri converts shredded waste from textile surfaces into high-quality fiber slivers for new yarns.

Clothings for recycling

As individual as your application

The wide range of clothings from Trützschler Card Clothing has been specially developed and tailored for Trützschler machines and the designated applications. The high performance of the card TC 30Ri for Recycling cannot be achieved without Trützschler clothings. Different aspects of the clothings are key, depending on which recycled material is to be processed.

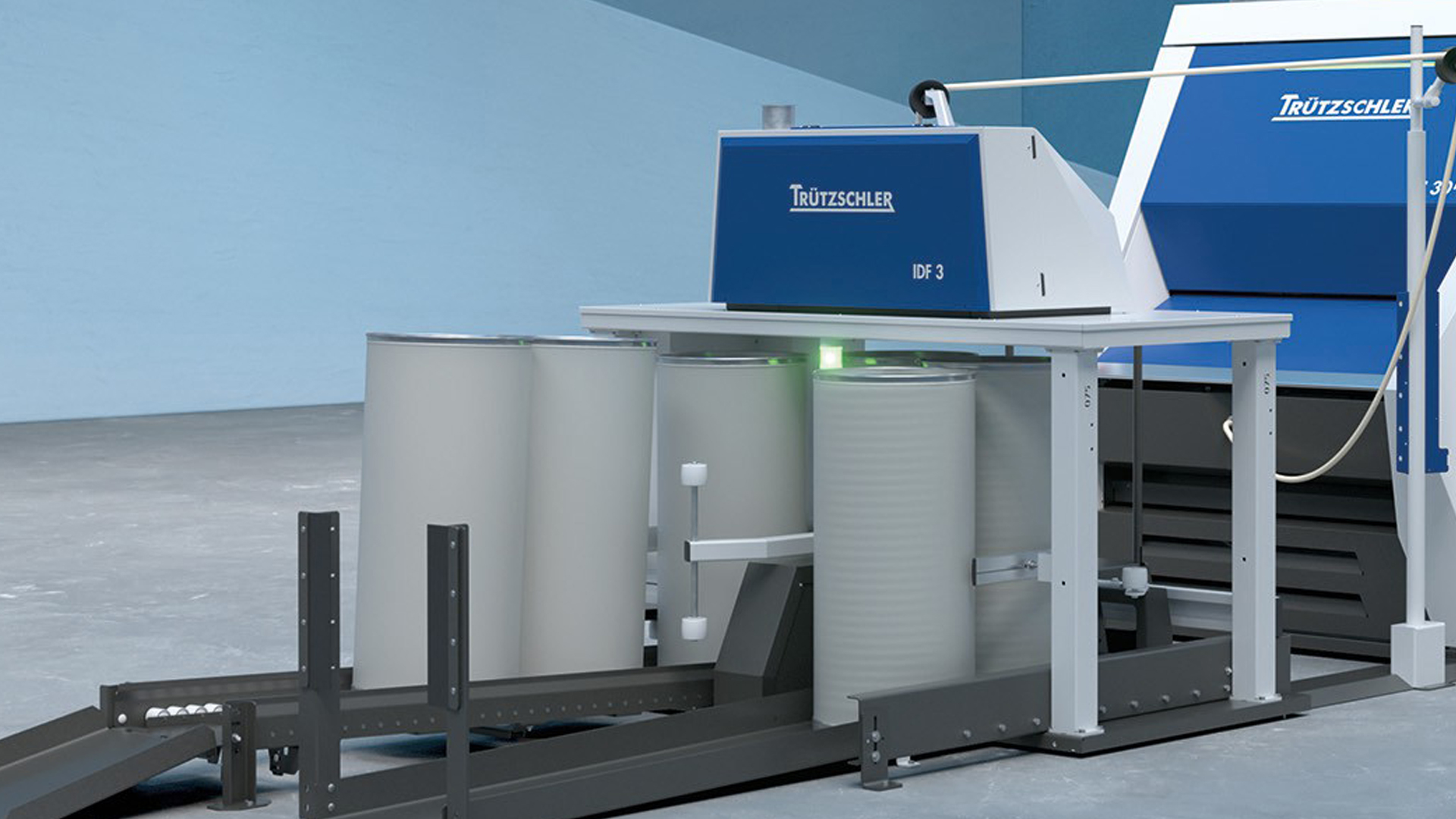

Integrated Draw Frame IDF 3

New generation: IDF 3

IDF 3 offers a range of innovative features that give customers even

better quality, efficiency and handling – as well as accelerated can change

times and improved productivity.