Trans-Textil GmbH

Address

Trans-Textil GmbH

Pommernstr. 11-13

83395 Freilassing

Germany

Telephone+49 8654 66070

Fax+49 8654 660710

Discover more from us

Follow us on

About us

As a technology leader in the lamination, finishing, coating and printing of multi-layer fabric systems with more than 40 years of experience, Trans-Textil produces high-quality membrane laminates “Made in Germany” certified to European standards for high-visibility clothing (EN 471), protective clothing for fire-fighters (EN 469 / HuPF), heat protective clothing (EN 11612), clothing for protection against foul weather (EN 343) and cold (EN 342), protective clothing with electrostatic properties (EN 1149), surgical gowns and drapes (EN 13795), safety shoes (EN 344) and in accordance with the Standard 100 by OEKO-TEX. Trans-Textil's products fulfill hightes ecological standards and are also used in leisure, sports and outdoor clothing as well as in technical applications such as the VAP lightweight manufacturing process.

Our product groups

Downloads

Documents

Keywords

- Outdoor

- Membranen

- Beschichtungen

- Laminate

- Schutzkleidung PSA PPE

Our Products

Topaz PURABLE: Funktionslagen auf wässriger Basis

Trans-Textil verzichtet bei atmungsaktiven und wasserdichten PURABLE Barriere-Systemen auf organische Lösemittel

Ihre PURABLE Funktionssysteme auf Basis wässriger Technologien präsentiert die Trans-Textil GmbH erstmals auf der Techtextil in Frankfurt am Main (Halle 12.1, Stand B67). Dabei verzichtet das Unternehmen aus Freilassing / Bayern in der Herstellung vollständig auf organische Lösemittel. In Kombination mit der PFC-freien Ausrüstung Clean4Green®, den wässrigen Topaz Elements® Nahtabdichtungsbändern, dem umweltschonenden Transferdruckprozess sowie vegan zertifizierten oder recycelten Komponenten entsteht so ein technisch äußerst flexibles und nachhaltiges Gesamtkonzept für Funktionstextilien.

Grundlage der PURABLE Funktionsschichten sind eigens entwickelte, lösemittelfreie Rezepturen, welche eine gezielte Steuerung technischer Eigenschaften wie zum Beispiel der Luftdurchlässigkeit und Atmungsaktivität erlauben. Die Barrieresysteme sind sehr dehnfähig und gewährleisten in Kombination mit elastischen Textilien einen komfortablen Stretch-Effekt sowie einen angenehm weichen Griff, selbst in mehrlagigen Verbünden. Mit über 50 Zyklen bei 60°C nach ISO 6330 hat Trans-Textil auch die hervorragenden Wascheigenschaften der neuartigen Systeme nachgewiesen. Im Einsatz als klassische Softshellprodukte kann so gänzlich auf den Einsatz von PTFE verzichtet werden, ohne jegliche Einbußen am entscheidenden Parameter der Wasserdampfurchlässigkeit.

Für eine entsprechende Wasserdichtigkeit werden bei Trans-Textil die hydrophilen, lösemittelfrei gefertigten PURABLE Membranen im exakt gesteuerten hauseigenen Point-in-Point® Laminationsverfahren zu individuellen Mehrlagenverbünden verarbeitet und erreichen dabei Dichtheitswerte von über 10 Metern Wassersäule.

Synergieeffekte mit PFC- und lösemittelfreien Technologien

In der weiteren Funktionalisierung für Wetterschutz-Anwendungen wie Workwear, Behörden-, Outdoor- und Sportbekleidung greift Trans-Textil auf seine bewährte PFC-freie Ausrüstung Clean4Green® zurück, die an den jeweiligen Laminatverbund angepasst wird. „Mit dieser alternativen und umweltschonenden Oberflächenveredelung erreichen wir bereits eine Wasserabweisung, die mit herkömmlichen Rezepturen auf Fluorbasis vergleichbar ist. Die eigentliche Dichtheit gegenüber Öl und anderen Chemikalien ist zudem durch das Membransystem gegeben“, so Matthias Krings, Geschäftsführer der Trans-Textil GmbH.

Für die modische Gestaltung der Funktionslaminate setzt Trans-Textil auf den umweltschonenden Transferdruckprozess, bei dem nur die natürlichen Lösemittel Wasser und Alkohol verwendet werden. Neben den individuellen Designoptionen vom Logodruck bis hin zu vollfarbigen Motiven bietet die nachhaltige Technologie hohe Farbechtheiten und Abriebbeständigkeit.

Nahtabdichtung auf wässriger Basis

Für optimale Dichtheit an den Nähten hat Trans-Textil lösemittelfreie Nahtabdichtungsbänder für alle gängigen Laminattypen entwickelt. Die Topaz ELEMENTS® Tapes auf wässriger Basis ermöglichen eine lange Nutzungsdauer von hochwertigen Funktionstextilien zum Beispiel in Schuhlaminaten, Arbeitskleidung, Outdoor-, Freizeit- und Sportkleidung sowie in technischen Konfektionen. Die Bänder können bezüglich technischen Eigenschaften, Abmessungen und Design individuell gestaltet werden. Sie sind für die Wäsche bei bis zu 60 Grad Celsius geeignet.

Vegan-Label für Membranen, Textilien und Laminate

Mit dem Prüfzeichen „100% Vegan“ des Prüf- und Forschungsinstituts Pirmasens (PFI) ausgezeichnete Membransysteme, Textilien und Laminationsprozesse sowie ein erhöhter Anteil recycelter Komponenten erweitern das nachhaltige Portfolio von Trans-Textil zusätzlich. Alle Komponenten und Prozesse für Eigenprodukte und die Lohnverarbeitung sind zudem nach den aktuellen Anforderungen des STANDARD 100 by OEKO-TEX® auf ihre humanökologische Unbedenklichkeit geprüft und zertifiziert.

Konkreter Beitrag zur Gesamtbilanz in der Lieferkette

Durch den verstärkten Einsatz wässriger und PFC-freier Technologien reduziert Trans-Textil den ökologischen Fußabdruck entlang der Lieferkette sowie in der Herstellung, während der Verarbeitung und im Gebrauch deutlich. „Mit diesen konkreten Beiträgen zur Gesamtbilanz geht unser Team weitere Schritte in der konsequenten Umsetzung unserer Nachhaltigkeitsziele“, erklärt Matthias Krings.

Dass dieser Weg neben den ökologischen Vorteilen auch technisch erfolgreich ist, hat Trans-Textil bereits mehrfach unter Beweis gestellt – so zum Beispiel mit dem „100% Vegan“ zertifizierten atmungsaktiven Kunstleder AQUAIR®, welches vollständig ohne organische Lösemittel hergestellt wird. Auch bei den Membransystemen für das VAP®-Leichtbauverfahren, für welche Trans-Textil gemeinsame Patente mit AIRBUS hält, ist der Umstieg auf rein wässrige Systeme gelungen. „Vor allem die Hersteller von Windkraftanlagen zur Energieerzeugung aus erneuerbaren Quellen prüfen die Umweltauswirkungen der eingesetzten Materialien sehr genau und fordern weltweit den Verzicht auf PFC‘s und organische Lösemittel“, erläutert Matthias Krings den Hintergrund des Erfolgs.

Ideale Voraussetzungen hat Trans-Textil durch den langjährigen Aufbau enger Partnerschaften in einer vorwiegend regionalen Lieferkette geschaffen. Kontinuierlich investiert der Betrieb in ein qualifiziertes Team, eigene anwendungs- und textiltechnische Labore sowie Anlagentechnik zur Verarbeitung wässriger Rezepturen, die kurze Wege von der Entwicklung bis zur Umsetzung am Standort Freilassing bieten

Cooperation for textile laser protection

The use of powerful laser systems is gaining in importance in many areas – and with it the need for intelligent solutions for the protection of people and technology. With their increased cooperation, JUTEC® GmbH and Trans-Textil GmbH are pursuing the goal of further expanding their joint development of multifunctional smart textiles for laser protection “Made in Germany”.

One focus of the partners is the active sensor technology: If a misdirected laser beam hits the textile multi-layer compound integrated detection layer, the radiation source is switched off automatically. The outer layer is a specially developed protective coating in pearly-colored optics, which diffuses incident rays by

diffuse reflection and thus also forms the basis for passive systems.

Made to order in Germany, the products of JUTEC® and Trans-Textil have been so reliable that employees and valuable production facilities work on automated laser workstations and manual laser workstations. Thanks to their high level of flexibility, the solutions are suitable for retrofitting previously passive protective cabins, as a freestanding mobile cabin for temporary workstations, individual curtains, mobile swivel arm systems or for lining machine components in which laser beams are generated.

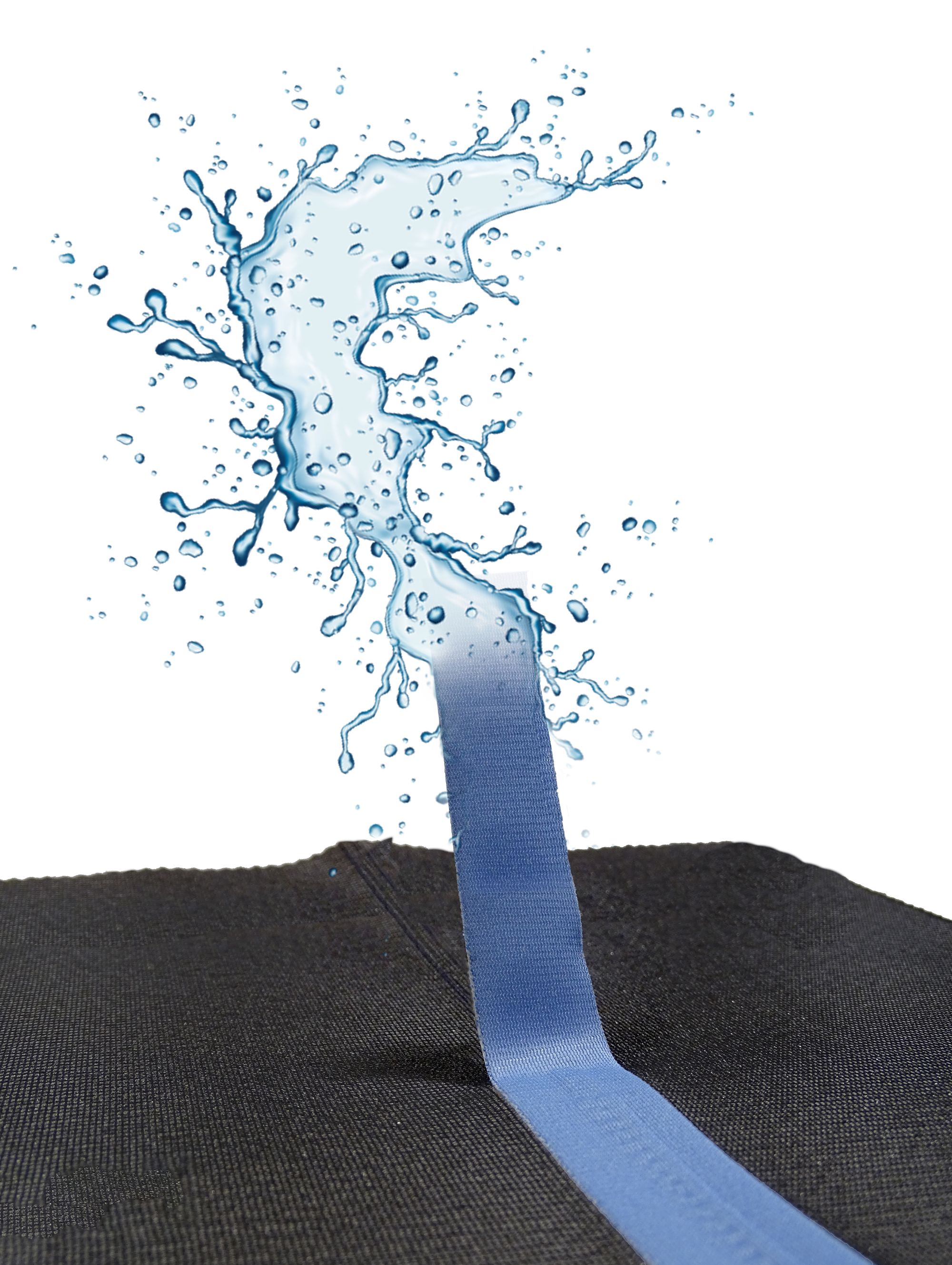

Seam sealing and repair patches for clothing and technical applications

To ensure that seams with the same characteristics as the laminate, Trans-Textil provides the tespective Topaz seam sealing tapes. We test our seam sealing tapes in our in-house lab to ensure that they fulfil all requirements for use in garment production and a broad range of technical applications. Topaz Tapes provide reliable sealing and a long service life of high quality functional apparel in a broad portfolio of applications:

- Shoe laminates

- PPE & Workear

- Surgical laminates

- Outdoor, leisture & sports wear

- Technical ready-mades

Thanks to flexible production techniques, the Topaz Tapes are specifically adapted to technical requirements in the garment production and application as well as to individual design requirements. Topaz Tapes are suitable for industrial laundry > 60 °C and are resistant to sterilization. With high technical performance they sustain the soft textile feel of the laminates even after several wash cycles.

Tapes for multi-layer laminates

Trans-Textil ensures that laminate, tape and further processing dovetail perfectly. We offer the compatible seam sealing tape for all requirements and 2- or 3-layer laminates.

Topaz Fusion Tapes

The Topaz Fusion Tapes bring reliable tightness and fashion together. Full-color designs matching the design of the laminate are realized in environmentally friendly and high-quality digital transfer printing – based on the flexible processes even for smaller production series.

Element Tapes

Based on a purely aqueous formulation in the adhesive layer, Topaz Elements Tapes not only fulfill a high technical profile le, but also meet the highest requirements for environmentally friendly products, processing and washing up to 60 °C.

Jumbo Tape

By individually confectioning Trans-Textil tailors the Topaz Tapes to the customer‘s wishes – from the narrow version to extra wide Jumbo Tapes.

Repair & patchingFor a long life cycle of high-quality functional laminates, the Topaz Tapes material is ideal for manufacturing compatible repair solutions.

High performance plus surgical fabrics in line with the EN 13795 standard

Thanks to its many years of experience, Trans-Textil is a reliable high-performance partner for industrial rental laundry services, hospitals and medical fabric manufacturers in the particularly critical medical applications field. Its laminates surpass the requirements of the respective standards and are biocompatibility-tested according to EN 10993.

Surgical gowns and drapes

Surgical laminates by Trans-Textil act as a reliable barrier against liquids and infectious agents and are also highly breathable.

In addition, they offer:

- 100% impermeability to microorganisms and liquids

- a high degree of breathability for professional comfort

- a degree of tear, bursting and tear propagation resistance that surpasses the require-ments of the respective standards

- virus impermeability even in cases of slight impairment of membrane system elasticity

- application-oriented particle and liquid control

Intelligent liquid control

Trans-Textil uses special polyester fabrics to optimise liquid control and hinder bacteria growth.

Such fabrics are used in situations involving a high occurrence of liquids and thus a high risk of infection. This is because they offer:

- several textile levels for an enlarged surface area and thus enhanced liquid uptake

- microfibers for additional surface area

- incorporation of auxiliary agents within the PES filaments for added hygiene

Liquid is not absorbed by the polyester fibres but taken up between them and transported away. As a result, the fabric dries quickly, giving bacteria little opportunity to grow and multiply.

Sustainable and economic

Topaz Medical reusable products are washable and ready for further use following reprocessing. This not only saves on costs and resources but also reduces waste – in line with the principles of a circular economy.

Reliable protection

Trans-Textil’s multifunctional laminates incorporating its high-tech membrane systems provide a truly impervious barrier to liquids, viruses and bacteria. And Topaz Tapes seam sealing technology en-sures impermeability at the seams.

Proven quality

As independent testing institutes affirm, Topaz Medical products conform to regulations and standards governing personal protective equipment and medical devices. Certification to STANDARD 100 by OEKO-TEX® attests to their human ecological soundness.

Production on a regional basis

The high-tech products ‘Made in Germany’ are fabricated in regional operations bolstered by strong partnerships and the flexibility of European supply chains.

Established service structures

All Topaz Medical products are developed and tested with textile leasing and industrial rental laundry services in mind. In all regions of Europe, professional laundry operations stand at the ready with local operations for textile reprocessing and comprehensive and convenient services.

Washable membrane laminates: the technology

Trans-Textil’s sophisticated Point-in-Point® lamination process ensures a long life cycle in repeated wear and washing.

On-going testing at the in-house test lab guarantees adherence to a consistently high quality standard.

Laminate-compatible Topaz Tapes seam sealing solutions provide dependable impermeability at the seams.

Repair solutions

In the interests of an economical and long-lasting life cycle, laminate-compatible patches are available in customizable sizes for repairing wear and tear.

Topaz FX: high-performance textiles reduce heat stress

Trans-Textil presents new generation of particularly light flame-retardant textile components with exceptional moisture management

The requirements for modern heat protection clothing are complex: they should offer a high level of protection and be as light as possible. Multi-layer multifunctional structures protect the wearer from heat and flames, wind and rain as well as from liquid chemicals and toxic particles. At the same time, a high level of thermophysiological comfort is required in order to keep the physical strain on the helpers as low as possible, because heat stress is one of the biggest risk factors in all demanding operational situations. With the new generation of Topaz FX lining fabrics and laminates, Trans-Textil GmbH offers a patented system that is highly breathable, efficiently transports sweat, optimally cools the body and thus reduces heat stress. The new Topaz FX products are extremely light and have an excellent protective effect despite their low weight.

The problem of heat stress

A person sweats about 200-700 milliliters per day on a skin area of about two square meters with average physical exertion. In action, firefighters sweat between one and two liters in just 30 minutes! The sweat produced by human skin cannot be released into the environment quickly enough through heavy and poorly breathable clothing - natural body cooling is reduced and heat build-up occurs. If the body is exposed to such a situation for a long time, the cardiovascular system is subject to extreme stress. This heat stress can even be fatal. Most firefighters' injuries are also due to slipping, stumbling and falling accidents. This risk also increases due to overload in the form of heat stress, which accelerates muscle exhaustion and affects cognitive abilities.

In addition to physical fitness, optimized clothing concepts and innovative materials are crucial to reduce heat stress. They combine protective function, comfort, moisture management and temperature regulation. The operational clothing has developed significantly thanks to new functional fabrics. The clothing is based on elements from sports and leisure garments for increased freedom of movement, function and well-being.

Topaz 251 Hightech PU-Membrane-system: 100% PU – 100% Performance

The construction of functional textiles themselves also plays an important role in relieving the relief forces. In the multi-layer laminate, robust and highly breathable membrane systems serve as protective moisture barriers against liquids and particles from the outside and at the same time ensure that body moisture is reliably released to the environment.

As a proprietary development of Trans-Textil, the Topaz 251 membrane system meets the highest requirements in application and processing. The in-house formulation of high-temperature-resistant polyurethane forms the basis for the extremely flexible application options. The bi-elastic Topaz 251 membrane is characterized by high heat resistance and breathability as well as reliable waterproofness. This makes it the versatile basis for high-performance laminates in the areas of certified PPE and multi-standard protective clothing, firefighting clothing, government clothing, reusable medical products and components for safety shoes. To ensure that the seams keep what the laminate promises in everyday use of functional clothing, Trans-Textil also offers compatible seam sealing tapes for all laminate types.

Relief through innovative material concepts

The decisive factor is the targeted coordination of all material components. Because the higher the ambient temperature, the more important it is to cool the body. This only works if the lining materials already absorb moisture and transport it away from the body. “This performance of lining materials is often underestimated. Too often you focus on the properties of the outer material, the performance is reduced to flame resistance and strength. We have recognized that the lining, as the innermost layer and direct connection to the body, plays an essential role in terms of moisture management, body heat transport and breathability, ”says Dipl.-Ing. Wilhelm Krings, managing director of Trans-Textil GmbH.

The "pull and push effect" can be used in the overall concept of the materials. The combination of water-repellent (hydrophobic) and water-attracting (hydrophilic) fiber materials in the moisture-dynamic structure of Topaz FX clearly favors climate regulation in the clothing network.

Topaz FX: Intelligent moisture management, lower weight and maximum breathability

Conventional production methods for flame-retardant textiles often reach their limits in further optimization. To produce lighter fabrics you need very fine yarns and special constructions. With Topaz FX, Trans-Textil has for the first time succeeded in creating tailor-made zones from high and low absorption areas in just one textile area. Liquid sweat is actively transported away from the body by a moisture-dynamic grid in a permanent 3D structure, spread over a large surface and can evaporate faster. In addition, reduced weight and measurably faster drying improve moisture management, increase comfort and reduce the risk of heat stress.

The patented Topaz FX technology can be applied to other textile materials for 2- or 3-layer laminates, base layers (functional underwear), head protection hoods or liners. Due to the individual design of functional zones, the concept not only offers excellent sweat management, but also unique opportunities for individual design in heat protection clothing as well as for public authorities, industrial or sports clothing.