TFI - Institut für Bodensysteme an der RWTH Aachen e.V.

Address

TFI - Institut für Bodensysteme an der RWTH Aachen e.V.

Charlottenburger Allee 41

52068 Aachen

Germany

Telephone+49 241 9679163

Fax+49 241 9679200

Discover more from us

Follow us on

About us

We are the institute for research, testing and certification in Europe for interior building products. With our developments, we shape the future and enable manufacturers of building and furnishing products to produce responsibly and sustainably - for the living and working of tomorrow.

Industry-oriented research that gets through.

We conduct research to develop future-proof technical solutions for our industry and to design interiors in the best possible way. To do this, we focus on issues of sustainability and the circular economy, health, safety, comfort and design.

We use our specialist knowledge, our experience, our modern infrastructure and draw on our large interdisciplinary network. In cooperative research projects, we develop new materials and products, innovative production techniques and technologies as well as testing methods.

Key topics:

Sustainability and circular economy – Health – Safety – Comfort – Design

Technologies:

Yarn development – tufting - shearing – coating – calendering – thermobonding – laminating – press forming – testing technology

Competencies:

We achieve excellent research results and ensure the transfer of innovations and new findings from science to industry. This enables us to identify future challenges and develop innovative solutions for our industry and thus for the interior of the future.

Machine technology – We analyze technologies and production processes, develop them further in a targeted manner and combine them with each other. We develop new production technologies and innovative machine elements. New and adapted manufacturing processes and value chains are created for innovative, functional, sustainable and therefore future-oriented products.

Digitalization – One of our tasks is to record and digitalize all material and process variables. This is how we create the conditions for greater productivity, sustainability and flexibility.

Simulation – The virtual, data-supported image of materials and processes created by simulation helps to significantly reduce previously empirical or experience-based adjustment and development efforts.

Measuring and testing technology – Based on a specific requirements profile, we define the product properties or measured variables that need to be recorded. We determine or develop application-specific measuring and testing methods and sensors.

Building physics – In the field of building physics, we address the topics of acoustics and heat. For research into acoustically and thermally effective system solutions, the TFI has extensive measuring and testing technology in addition to laboratory and pilot plant facilities. This includes, for example, the building acoustics laboratory and an acoustic and infrared camera for localizing and visualizing sound and heat sources.

Application technology – We transfer scientific findings safely and in line with requirements into practical applications. This enables us to offer competitive solutions and services that are highly valued in the industry.

Our product groups

- Research, Development, Education, Consulting

Our application areas / Solutions

More about us

Special Interests

Keywords

- Bodenbelag

- Bauprodukt

- Geotextil

- Akustik

- Filter

Our Products

Textile heat exchanger - double loop structure made of metal yarn

For the IGF project 20540, a flexible "textile" heat exchanger element was developed for use in systems for decentralized domestic ventilation.

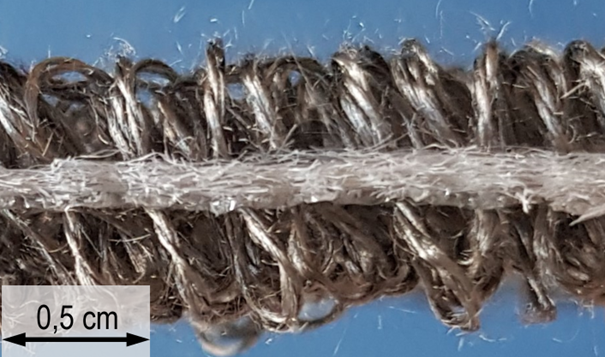

The approach pursued was to produce a double-loop structure from metallic yarns separated by a flexible textile. For textile production, a tufting machine was modified in such a way that the dead pile, which normally lies flat on the carrier, is raised and thus also forms loops. A spunbonded nonwoven fabric with a hotmelt film was used as the tufting backing. After tufting, the hotmelt adhesive was melted to bond the yarns to the carrier and improve the airtightness of the spunbonded nonwoven.

The yarns used were stainless steel fiber yarns and copper strands.

Tufted Geotextiles

Tufted geotextiles extend their effect into the third dimension and thus offer the vegetation a supportive hold. In the event of heavy rainfall, they prevent the erosion of shallow-rooted plants or grasses and hold the soil firmly against the flow pressure. They achieve this effect on road embankments or sloping surfaces as well as on flooded areas or river banks as part of flood protection or infrastructural adaptation to extreme precipitation caused by climate change. Funding program: IGF 20323 N

However, tufted geotextiles are also capable of greening our cities in the context of the EU-wide green deal and thus improving the microclimate. Thanks to their textile structure, they give the growing substrate for façade greening a firm hold by allowing the plant roots to interlock with the threads and also ensure the supply of moisture and nutrients by integrating nonwovens into the textile tufting construction.

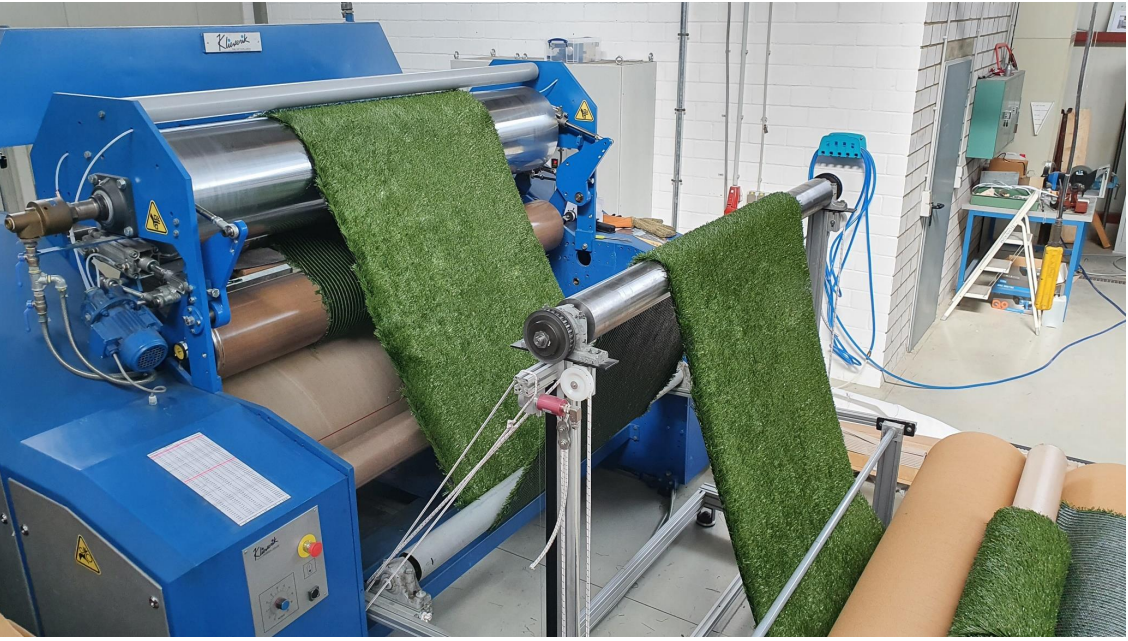

Bio-based artificial turf

Bio-based artificial turf systems reduce greenhouse gas emissions by 133,390 tons of CO2 equivalent (based on new installations across Europe in the reference year 2023) due to the use of bio-based materials for the pile material and thermal integration of the pile material into the carrier. A bio-based artificial turf, made from rapeseed oil, was developed as part of the BioTexFuture innovation area BMBF (031B1213A). In order to reduce microplastic emissions, which are unavoidable in today's artificial turf systems due to the stabilizing infill granules, BioTurf uses a second yarn that is structured and integrated in such a way that it meets the elastic properties of a FIFA-certified standard. A further step towards sustainability is the elimination of the latex bond between the tufted pile yarns and the textile backing. Thermobonding (see photo) offers a technical solution here, which also saves the energy-intensive drying of the latex. The result is an artificial turf that consists of one polymer group for better recycling, contains no microplastics and is made from renewable resources.

Funding program: BioTexFuture 031B1213A