Textilforschungsinstitut Thüringen-Vogtland e.V.

Address

Textilforschungsinstitut Thüringen-Vogtland e.V.

Zeulenrodaer Str. 42

07973 Greiz

Germany

Telephone+49 3661 6110

Fax+49 3661 611222

Discover more from us

Follow us on

About us

TITV Greiz - the Institute for Special Textiles and Flexible Materials

TITV Greiz was founded in February 1992 as a non-profit, industry-oriented research institute and concentrates on application-oriented research in the areas of textile microsystems technology/smart textiles, surface functionalization and flexible materials. Research and development projects are increasingly focusing on issues relating to current future fields, such as electromobility, resource conservation, recycling, sustainability, digitalization and demographic change.

More than 60 employees work on high-tech solutions in which new functionally integrated materials are produced using classic textile technology in combination with special surface modifications and, in some cases, technologies that are unusual for textiles. This takes place primarily in interdisciplinary project groups as well as in cooperations and numerous national and international networks, in which a number of universities and institutes are involved alongside companies. Together, innovative materials are developed on the basis of textile structures, which are characterized by their flexibility, low weight and reliable function. The combination of electronics and textiles in particular is used to develop innovative textile products for completely new areas of application.

TITV Greiz has been involved in the development of smart textiles for almost 25 years. While developments initially focused on textile-adapted and textile-based electronic or sensory functionalities and their reliable function, the focus of developments is now increasingly shifting to the sustainable construction and design of smart textiles and thus both the use of sustainable and renewable raw materials and the creation of a way to repair smart textiles.

The medium-term and overarching research goal at TITV Greiz is to map and research the cradle-to-cradle process from the creation of a smart textile through to its recycling and subsequent return to the production cycle.

TITV Greiz has extensive scientific and technical expertise in the fields of thread formation, textile surface formation, textile finishing, CVD processing, electrical engineering, textile physics and chemistry studies and technology transfer at national and international level. In addition to technical centers for the textile processing chain, TITV Greiz has an electronics laboratory, Smart Textile testing laboratory and an accredited testing center for the practical implementation of research and development services.

In recent years, TITV Greiz has invested in modern facilities for research and development along the entire textile chain.

In addition to a prototype laboratory for functional thread materials, investments have been made in modern machines along the entire textile chain and a development laboratory for the digital networking of textile production processes and non-textile functionalization for the fast, reliable and scalable development of smart textiles for the industry.

Most recently, a robot-assisted recognition and sorting system for the automatic, energy- and resource-efficient separation and recycling of electronic textiles for return to the production cycle of new smart textiles products was set up in 2023. TITV Greiz is thus able to map smart textiles throughout their entire "life cycle" - from concept/design to research and development through to recycling, while at the same time taking into account energy- and resource-efficient processes and materials.

This technical potential and the many years of expertise of our employees guarantee the development of processes and products according to the individual requirements of our customers. Based on current market trends and state-of-the-art machine technology, our user-related developments are used in medicine, vehicle construction, protection and safety technology, microsystems technology, sports and wellness as well as in the large field of industrial textiles.

In order to counter the increasing shortage of skilled workers in the textile industry, TITV Greiz is actively involved in the training and further education of skilled and junior staff. This begins with several students taking the opportunity to write their internship, bachelor's or master's thesis at the institute during the year. TITV also offers students and academic staff from universities and technical colleges the opportunity to supplement their academic training by working on research projects at the institute.

Our product groups

- Woven Fabrics, Laid Webs, Braidings, Knitted Fabrics

- Functional Apparel Textiles

Our application areas / Solutions

Keywords

- Oberflächenfunktionalisierung

- Textilprüfung

- Seminare

- Smart Textiles

- Forschung und Entwicklung

Our Products

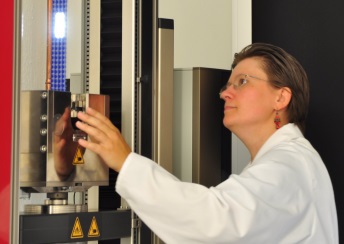

Smart textile test laboratory

Especially products with electric conductive components, like traces for heating or lightning applications or textile sensors, contactings between individual components of the smart textiles as well as interaction between the textile and textile-atypical, unflexible components have to be tested. The purpose of the testings is to assess the processability of new materials, to evaluate lifetime and deficits of the products, not at least for the users safety.

In a special smart textile test laboratory textile and electronic test methods will be adapted and combined with stress simulations.

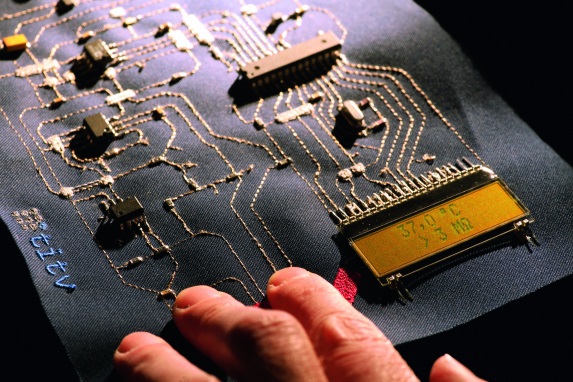

Smart Textiles

Electronical assistants like navigation systems or parking distance control systems help us to make life easier. Those small, close and intelligent systems are integrated in our personal and business environment and can even be found in textiles (smart textiles). Clothing, which warms at low temperatures or gloves to phone with are already commercially available.

To realize such functionalities, small electronical components are integrated into textiles or the textile itself is used as a functional unit. The basis for those developments are partial conductive textile structures. Metallized threads whose electrical conductivity is modified with a specific electrochemical finishing treatment – so-called ELITEX® threads – provide the convincing advantage of problem-free textile machining on textile machines.

Textile manufacturing processes like weaving, embroidery, sewing, warp knitting or coating can be used for the integration of new functions for textiles. The resulting textile structures are the basis for the development of textile sensors, highly flexible stimulation electrode systems, actuators, solar cells, textile transdermal therapeutical systems, for the interactive release of active ingredients, luminescent textiles or special heating systems.

Developments for the integration of new functions provide capabilities for further visions. In comparison to conventional products, smart textiles are flexible shapeable and lightweight. They are predestined for applications in automotive and aircraft construction as well as for solutions in medical engineering, wellness, industrial-, home- and protective clothing.

Flexible Materials

Textiles are versatile materials or the basis for functional and flexible applications.

The main research field Flexible Materials creates lightweight and flexible structures by means of textile technologies. Current trends of the markets and modern technical equipment offer customer-related product development and innovation not only for textile companies. Selected initial research investigates new technologies for the manufacturing and functionalising of flexible structures on a textile basis, like fabrics and thread constructions for medical or technical applications.

For multi-focus tasks, these fabrics and thread constructions can be further processed in following research groups like coating or smart textiles.

The main research field Flexible Materials provides also technological solutions for textile companies with the help of technical schools for thread constructions, weaving, braiding, embroidery and three-dimensional knitting, which are also available for customer tests and sample specimen.

Technical labs of the TITV Greiz

Basis for successful research projects as well as for contract research and services is our modern and extensive equipment in our technical labs. We are in the position to realise all individual requirements of our customers along the textile chain from a single thread to the final product.

Functional Surfaces

New applications for textiles in technics, electronics and microsystems technique can be opened up with functional surfaces as they can be created through innovative coatings. Textile boundary surfaces can be changed individually through physical or chemical processes to adapt their properties regarding adsorption, repulsion, porosity, molecular identification or the controlled release of active ingredients.

Technologies like coating or lamination will be further enhanced to assure their process reliability. It is the goal to look for materials and processes to develop functional coatings and laminations with finest structures at the nanoscale. The challenge here is the use of new materials.

Especially electroluminescent substances, conductive polymers or flame-retardant composites are investigated, regarding constructive coating technologies like the galvanic coating of textile structures.

Opening new fields for textiles with functional coatings and creating composite structures with additional properties for applications in technics and microsystems technology is the main focus in our research work. Different technologies like coating and laminating will be enhanced to assure their process reliability.

First results in the development of light shield systems for museums, high-conductive fiber materials and structured conductive surfaces for smart textiles can be presented.

A soil-repellent Sol-Gel finishing, textile electroplating, onesided finishings of three-dimensional textiles and the preparation of textiles for inkjet printing demonstrate our professional competence too.