Shelton Machines Ltd.

Shelton Machines Ltd.

No. 1, Priory Business Park, Wistow Road

Kibworth, Leicestershire

LE8 0RX

Great Britain and Northern Ireland

Telephone+44 116 279 0920

Fax+44 116 279 0921

About us

- Shelton Vision are a leading producer of machine vision sytems for the textile industry able to inspect both plain single colour and PATTERNED fabrics at high speed and high accuracy.

- Our systems are marketed under the WebSpector Textile Inspection Systems brand and are suitable for all demanding fabric inspection requirements.

- The systems employ Machine Leaning in terms of auto setting inspection leveles to each individual style and Small Data AI for defect classification (naming) and grading in real time during inspection.

- Inspect in process (printing, laminating, finishing etc.) to maximise the benefits.

- We concentrate on developing ever more efficient systems with unique features for our customers in the apparel, automotive interior, workwear and many other textile fabric production sectors.

- WebSpector autmated fabric inspection systems for PLAIN and PATTERNED fabric.

- Automatically inspect printed, yarn dye and jacquard fabric after finishing.

- Inspect printed fabric in process on the print line to limit defect severity.

- Real time defect detection, classificatin (naming) and grading in terms of severity.

- One Piece Woven (OPW) airbag inspection and dimension check.

- Cut part dimension check and inspection.

- Cut plan optimisation to maximise yield for cutting rolls and packing.

- Fabric direction and orientation check systems.

- Defect sample testing and consultancy.

Our product groups

- Technology and Processes

Our application areas / Solutions

Keywords

- Digital inspection system

- Vision systems

- camera inspection system

- Fabric inspection systems

- Automatic fabric inspection

Our Products

Shelton SMW- On Loom Inspection

More than 90% of cost of producing cloth on a loom is accounted for by the cost of the raw material. Therefore it is desirable to prevent defects from occuring, or if they do occur from continuing.

It is also desirable not to have to handle the cloth after weaving for a searate inspection process.

By inspecting automatically directly on the loom running defects can be minimised and a defect map created to assist in high speed rolling at mending.

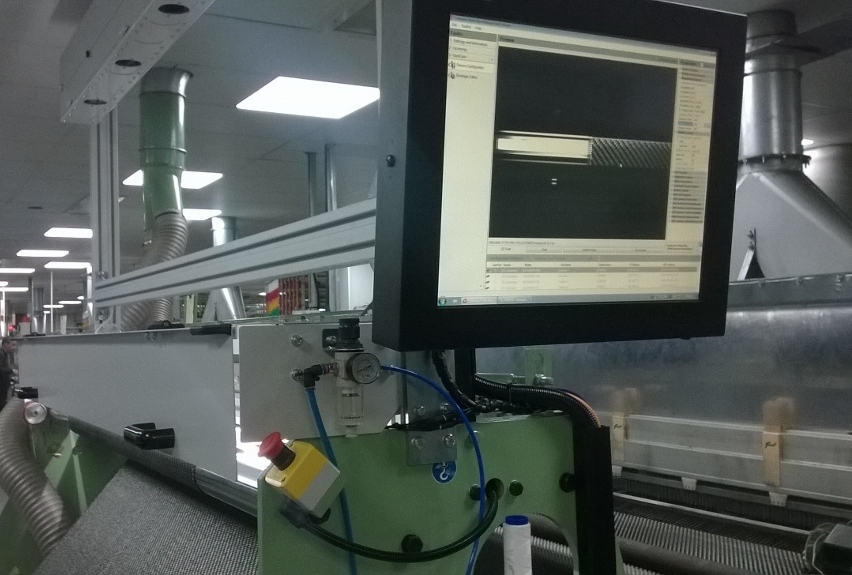

A camera based system incorporating Shelton Visions proprietary defect detection software, developed for high speed defect detection.

The SMW (slo moving web) inspection system uses state of the art camera technology with low cost but efficient processing unts to provide a cost effective on loom automatic insection solution.

Shelton WebSpector - Lite

An automated fabric inspection system tailord for lower speed, less demanding applications where space limitations apply.

Working width up to 5.5metres, speed up to 35 mtres per minute, multiplexed image planes for smaller footprint. Full WebSpector capabiity can be provided with options of record and inspect, real time defect classification and grading. Fully automated style autotraining.

Shelton WebSpector - Automated Textile Inspection System

A fully automated high speed camera based inspection system developed to inspect textiles either in process (eg stenter, compactor, sanforiser, laminator etc.), or as part of a purpose built high speed fabric transport machine running from reel to reel or A frame to A frame.

Return on investment is from multiple sources including increased rolling throughput, so lower labour costs, increased material utilisation from accurate and optimised cut plan creation and reduction of customer claims.

- Operating at speeds in excess of 100m/minute, defects are detected, classified and graded in real time.

- An electronic defect map is created and may be optiised for cutting to smaller pieces with resulting benefits from increased yield.

- Defect reporting can be achieved directly form the system.

- Customer claims can be challenged with video evidence of fabric condition at the time of inspection.

- The system has an autotrain function and classifies (names) and grades defects in real time.

Shelton WebSpector - Lite

An automated fabric inspection system tailord for lower speed, less demanding applications where space limitations apply.

Working width up to 5.5metres, speed up to 35 mtres per minute, multiplexed image planes for smaller footprint. Full WebSpector capabiity can be provided with options of record and inspect, real time defect classification and grading. Fully automated style autotraining.