The exhibitors & products at Techtextil 2026 will be available here from mid-January 2026.

Meichengxuan (Tianjin) Technology Co., Ltd.

Meichengxuan (Tianjin) Technology Co., Ltd.

Tianjin

Beichen District

No.026 South Jinyong Road, Shuangkou Town

300000

China

Telephone+86 186 2208 4819

Follow us here

Hall9.0

BoothB28c

About us

Mei cheng Xuan Tianjin technology Co. , LTD located in

northern Tianjin Which is an integrative city of Beijing,

Tianjin, and Hebei province, specialized in suspension

fork's research and developmen , production

manufacturing and vendition in environmental bicycle

industry. Under the principle of satisfying customers, we

would provide more comprehensive service for customers. Our company possesses a professional product design,

research and development team, leading production

management concepts and advanced equipment and

manufacturing processes, strict quality control system. Our products involve carbon fiber, magnesium alloy,

aluminum alloy, steel and other materials. Our products

are mainly exported to European and American and other

international markets, and gained much trust from them.

Mei cheng Xuan Tianjin Tenchnology Co. , LTD welcome you

to cooperate with us sincerely

northern Tianjin Which is an integrative city of Beijing,

Tianjin, and Hebei province, specialized in suspension

fork's research and developmen , production

manufacturing and vendition in environmental bicycle

industry. Under the principle of satisfying customers, we

would provide more comprehensive service for customers. Our company possesses a professional product design,

research and development team, leading production

management concepts and advanced equipment and

manufacturing processes, strict quality control system. Our products involve carbon fiber, magnesium alloy,

aluminum alloy, steel and other materials. Our products

are mainly exported to European and American and other

international markets, and gained much trust from them.

Mei cheng Xuan Tianjin Tenchnology Co. , LTD welcome you

to cooperate with us sincerely

Our product groups

Keywords

- FORK

- E BIKE

- BICYCLE

- SPOKE

- NIPPLE

Our Products

E BIKE

Frame: 27.5" Alu Alloy MTB Ebike

Speed: Shimano 7-12

Brake: Disc Brake

Motor: 48V 350W

Speed Range: 25-28km/h

Distance: 80-100km

Tyres: 29"*2.10

Size: 143*22*76cm

Speed: Shimano 7-12

Brake: Disc Brake

Motor: 48V 350W

Speed Range: 25-28km/h

Distance: 80-100km

Tyres: 29"*2.10

Size: 143*22*76cm

Trade fair innovation

SUS FORK

MCX-801 29" Magnesium Sus fork, Alloy Taper Steerer,Forged AL Crown, AL Black stanchion and 140mm outside Travel ,Magnesium lower Leg

Wheel Size: 29"

Steerer: Al6066 Aluminum ConeStandpip

Crown: Forged Al6061/130

Features:Remote/Hydraulic Air Lock-Out

Stanchion: 30/32mm Al6066/Hi-Ten Tube(CP)

Lower Leg: One-piece Aluminum

Brake Type: Only Disc Brake

Travel: 100 120

Wheel Size: 29"

Steerer: Al6066 Aluminum ConeStandpip

Crown: Forged Al6061/130

Features:Remote/Hydraulic Air Lock-Out

Stanchion: 30/32mm Al6066/Hi-Ten Tube(CP)

Lower Leg: One-piece Aluminum

Brake Type: Only Disc Brake

Travel: 100 120

SPOKE

Tianjin lei fa industry and trade co., LTD., is located in the beautiful scenery, pleasant environment, developed industry, rich products of the bohai sea regional economic center —— Tianjin, China, land and water transportation is very convenient.

The thunder spoke was created on February 13,1995 and has been developing for nearly 30 years. Honesty and pragmatism are our business purposes; quality first, service first is our business policy; in nearly 30 years we use advanced equipment and technology, and quality after-sales service system to meet the different needs of customers.

Our company is specialized in the production and sales of spokes entity factory, the main products are bicycles, electric vehicles, tricycles, motorcycles and other types of supporting spokes. Spoke varieties are: electroplating, twist, electrophoresis, plastic spraying, stainless steel, opposite sex, etc., complete specifications, reliable quality. Advanced production technology, strong technical force. With the annual production capacity of 20 million vehicles supporting the production capacity, and has a perfect management system and complete testing equipment.

In the past 30 years, "Leifa spoke" has always adhered to the core values of "quality factory, efficiency factory, service factory, realistic and innovation, learning and growth, the courage to break through". We are willing to make continuous breakthrough, continuous innovation, excellence, to provide you with the best quality products and services.

Welcome domestic and foreign merchants to visit you!

The thunder spoke was created on February 13,1995 and has been developing for nearly 30 years. Honesty and pragmatism are our business purposes; quality first, service first is our business policy; in nearly 30 years we use advanced equipment and technology, and quality after-sales service system to meet the different needs of customers.

Our company is specialized in the production and sales of spokes entity factory, the main products are bicycles, electric vehicles, tricycles, motorcycles and other types of supporting spokes. Spoke varieties are: electroplating, twist, electrophoresis, plastic spraying, stainless steel, opposite sex, etc., complete specifications, reliable quality. Advanced production technology, strong technical force. With the annual production capacity of 20 million vehicles supporting the production capacity, and has a perfect management system and complete testing equipment.

In the past 30 years, "Leifa spoke" has always adhered to the core values of "quality factory, efficiency factory, service factory, realistic and innovation, learning and growth, the courage to break through". We are willing to make continuous breakthrough, continuous innovation, excellence, to provide you with the best quality products and services.

Welcome domestic and foreign merchants to visit you!

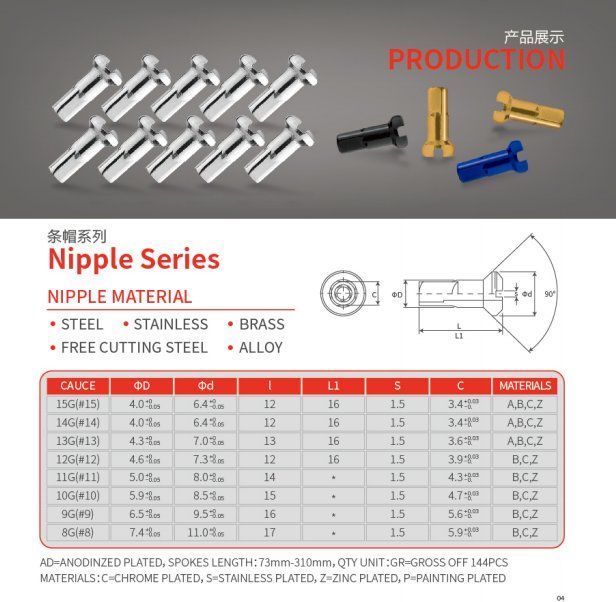

NIPPLE

Tianjin lei fa industry and trade co., LTD., is located in the beautiful scenery, pleasant environment, developed industry, rich products of the bohai sea regional economic center —— Tianjin, China, land and water transportation is very convenient.

The thunder spoke was created on February 13,1995 and has been developing for nearly 30 years. Honesty and pragmatism are our business purposes; quality first, service first is our business policy; in nearly 30 years we use advanced equipment and technology, and quality after-sales service system to meet the different needs of customers.

Our company is specialized in the production and sales of spokes entity factory, the main products are bicycles, electric vehicles, tricycles, motorcycles and other types of supporting spokes. Spoke varieties are: electroplating, twist, electrophoresis, plastic spraying, stainless steel, opposite sex, etc., complete specifications, reliable quality. Advanced production technology, strong technical force. With the annual production capacity of 20 million vehicles supporting the production capacity, and has a perfect management system and complete testing equipment.

In the past 30 years, "Leifa spoke" has always adhered to the core values of "quality factory, efficiency factory, service factory, realistic and innovation, learning and growth, the courage to break through". We are willing to make continuous breakthrough, continuous innovation, excellence, to provide you with the best quality products and services.

Welcome domestic and foreign merchants to visit you!

The thunder spoke was created on February 13,1995 and has been developing for nearly 30 years. Honesty and pragmatism are our business purposes; quality first, service first is our business policy; in nearly 30 years we use advanced equipment and technology, and quality after-sales service system to meet the different needs of customers.

Our company is specialized in the production and sales of spokes entity factory, the main products are bicycles, electric vehicles, tricycles, motorcycles and other types of supporting spokes. Spoke varieties are: electroplating, twist, electrophoresis, plastic spraying, stainless steel, opposite sex, etc., complete specifications, reliable quality. Advanced production technology, strong technical force. With the annual production capacity of 20 million vehicles supporting the production capacity, and has a perfect management system and complete testing equipment.

In the past 30 years, "Leifa spoke" has always adhered to the core values of "quality factory, efficiency factory, service factory, realistic and innovation, learning and growth, the courage to break through". We are willing to make continuous breakthrough, continuous innovation, excellence, to provide you with the best quality products and services.

Welcome domestic and foreign merchants to visit you!

FORK

MCX-763D

Wheel Size: 24" 26" 27.5" 29"

Material: Aluminum Alloy

Lower Leg: 31.8mm Triangle Shap 50*20

Ends: Alloy Forged Ends

Stem: 50*30*28.6/56*39.8*28.6 Al/Steel

Tyre Clearance: 72/80mm

Wheel Size: 24" 26" 27.5" 29"

Material: Aluminum Alloy

Lower Leg: 31.8mm Triangle Shap 50*20

Ends: Alloy Forged Ends

Stem: 50*30*28.6/56*39.8*28.6 Al/Steel

Tyre Clearance: 72/80mm

Our Contact Persons

Ken Li

Sales

CEO