Pontacol AG

Pontacol Cox997, our contribution to the circular economy of textiles

Explore product

Pontacol Cox997, our contribution to the circular economy of textiles

Explore product

Pontacol Cox997, our contribution to the circular economy of textiles

Explore productAbout us

First competence center for thermoplastic adhesive films.

Pontacol develops and sells thermoplastic adhesive films for industrial applications in the textile, composite, electronics, ballistic protection and personal care markets. Pontacol extrudes and produces technically sophisticated adhesive films not only for its own needs, but also as a contract manufacturer for third-party companies.

Pontacol’s product range includes mono-extruded and co-extruded flat and blown films with and without backing. These are complemented by functional films used as breathable membranes or blackout films.

Pontacol adhesive films: When easy handling is the focus

Pontacol adhesive films are heat-activated adhesives on a roll. They are not tacky at room temperature and can therefore be used very cleanly and efficiently. The ease of handling and repositioning capability results in minimal waste during substrate coating and lamination. Decades of development and application characterize our product portfolio. This know-how and Pontacol’s comprehensive range of products allows us to cover a wide range of applications with a wide variety of substrates, processing temperatures and high heat levels.

Pontacol multilayer adhesive films: Best choice for difficult substrates

Pontacol multilayer adhesive films are the perfect solution for incompatible substrates. This allows difficult or incompatible substrate combinations to be bonded together. For example, bonding polypropylene to polycarbonate can be implemented using a multilayer film without the use of a primer.

Pontacol adhesive film data: flat films, blown films, slitted films

Film weight: 10 to 1000 g/m²

Width: 9 to 3100 mm

Unsupported, silicone paper backing, PE carrier, PP carrier, high temperature resistant polymer carrier, coated or co-extruded carriers

Polymers:

- PE, LDPE, LLDPE, HDPE

- PP

- EVA, EAA, ethylene terpolymers

- PA, CoPA

- PES, CoPES

- TPU

- PVDF

- Blends

- various difficult to process polymers

Our product groups

- Bondtec (Surface & Bonding Techniques)

Our application areas / Solutions

More about us

Special Interests

Thermoplastische Klebefilme

Keywords

- Adhesivefilm

- Klebefilm

- Adhesive

- Adhesivetape

- Multilayerfilm

Our Products

Pontacol Functional Adhesive Films

Pontacol Functional Adhesive Films: the all-rounders.

Pontacol functional adhesive films guarantee perfect bonding to substrates and offer in additional functions matched to individual demands from customers. It means that you get an adhesive film with additional functional properties all in one.

Use as a liquid or light barrier

Our functional adhesive films can for example be used as a safe barrier for water and liquid chemicals (fuel, oil, solvents) or they can help, as Blackout Film, to prevent any penetration of light. Optionally, they can as Membranes ensure steam permeability of substrates, even after bonding.

Pontacol Blackout Film

Pontacol Blackout film: added value for manufacturers and users of blockout fabrics

Pontacol blackout film offers a soft textile feel, a high degree of whiteness and a highly effective darkening. Manufacturers will appreciate the ease of use of the blackout film since Pontacol adhesive films guarantee a uniform coating weight across the entire fabric length and width. Moreover, their production is made by an extremely eco-friendly process.

Pontacol 40.590 (850-1)

Base: Modified Polyolefin

Colour:White

Melting Range adhesive layer: 90-100°C

Heat deflection temperature: 65°C

Special properties:Opaque (Blackout)

Pontacol Monolayer Adhesive Films: When easy handling is the focus

Pontacol Monolayer Adhesive Films: When easy handling is the focus

Pontacol adhesive films are heat-activated adhesives on a roll. They are not tacky at room temperature and can therefore be used very cleanly and efficiently. The ease of handling and repositioning capability results in minimal waste during substrate coating and lamination. Decades of development and application characterize our product portfolio. This know-how and Pontacol’s comprehensive range of products allows us to cover a wide range of applications with a wide variety of substrates, processing temperatures and high heat levels.

Pontacol adhesive film data: flat films, blown films, slit films

Basis weight: 10 to 1000 g/m²

Width: 9 to 3100 mm

Unsupported, silicone paper backing, PE carrier, PP carrier, high temperature resistant polymer carrier, coated or co-extruded carriers

Polymers:

- PE, LDPE, LLDPE, HDPE

- PP

- EVA, EAA, ethylene terpolymers

- PA, CoPA

- PES, CoPES

- TPU

- PVDF

- Blends

- various difficult to process polymers

Pontacol Multilayer Adhesive Films

Pontacol Multilayer Adhesive Films: the best choice for problematic substrates

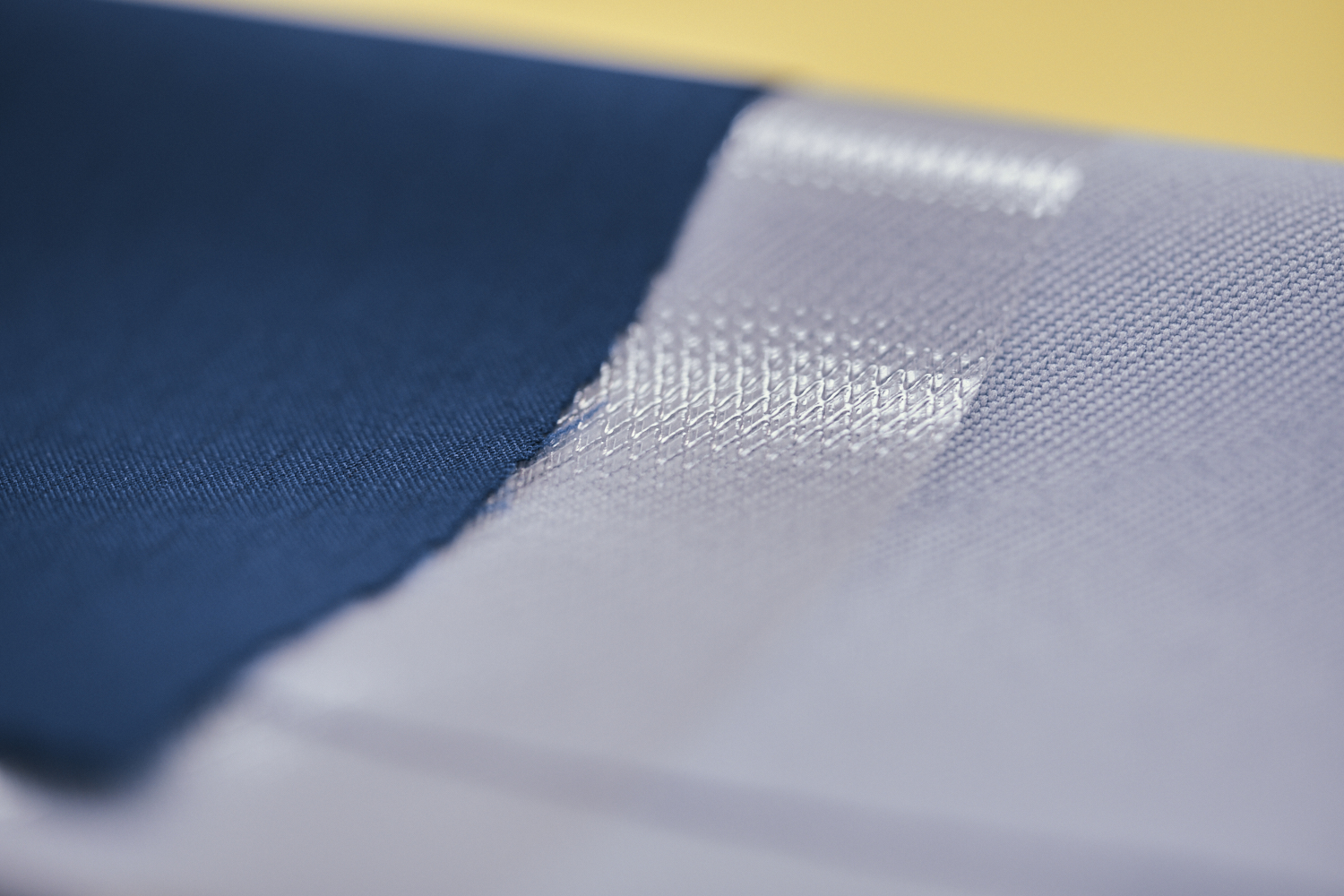

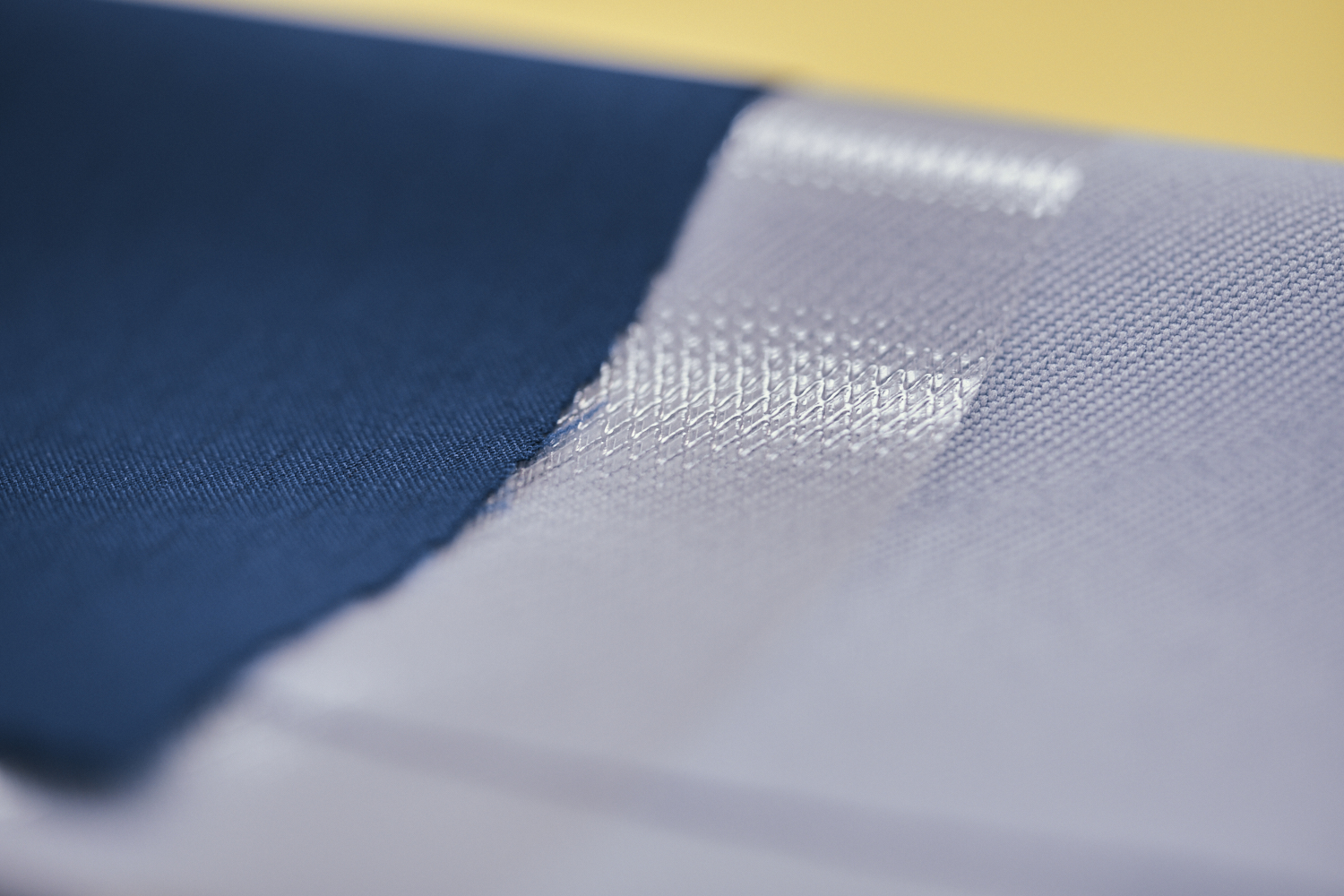

Our multilayer adhesive films are the perfect solution for incompatible substrates. They enable problematic or non-compatible substrate combinations to be bonded one to another. For example, incompatible polypropylene and polycarbonate can easily be bonded by using a co-extruded multilayer film and without the need of a primer.

Pontacol Multilayer Adhesive Films: the best choice for problematic substrates

Sheet Films / Blow Films / Slit Films

Weight: 10g/m2 to 500g/m2

Width: 10 mm to 3000 mm

Carrier free, Siliconpaper carrier, PE-carrier

Polymers:

- PE, PE-LD, PE-LLD, PE-HD

- PP

- EVA, EAA, ethylene terpolymers

- PA, CoPA

- PES, CoPES

- TPU

- Blends

Pontacol Cox997, our contribution to the circular economy of textiles

Pontacol Cox997 paves the way for a circular economy of textiles

Pontacol Cox997 is a new CoPolyamide adhesive film with 80% renewable raw materials and an 80% reduced CO2 footprint compared to petroleum-based adhesive films. Polyamide/nylon textiles that are bonded with CoPolyamide films can directly be melted and reused.

Our range of high-quality adhesive films for clothing and technical textiles contributes significantly to increasing the quality and lifespan of the end products, meaning they can be used for longer and therefore generate less waste. However, it is inevitable that certain materials will end up as waste or unusable residue at the end of life, which is why recycling plays a crucial role.

Textiles made from artificial fibers that are bonded with adhesive films of the same polymer base can be directly shredded, melted and recycled back into the fiber manufacturing process as granules.

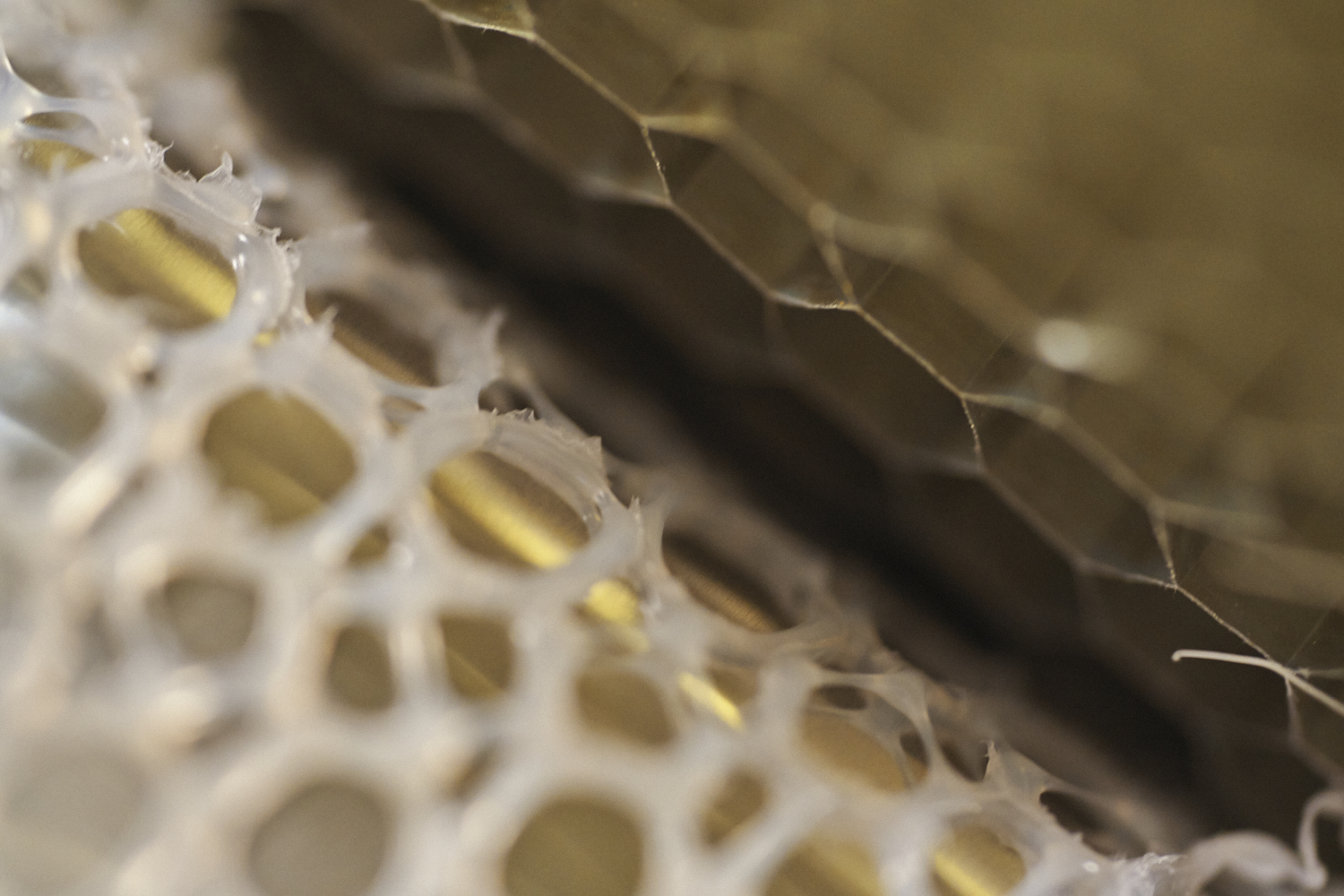

Picture: Pontacol adhesive films based on a broad variety of polymers

Laminates that are made of different materials and have been bonded with Pontacol adhesive films can be separated again by exposure to temperature and individually fed into the recycling process.

In addition to the outstanding recyclability of thermoplastic adhesive films, Pontacol is intensively committed to the development of new films with a reduced CO2 footprint or made from renewable raw materials.