Polyvlies Franz Beyer GmbH

Polyvlies Franz Beyer GmbH

Rodder Str. 52

48477 Hörstel

Germany

Telephone+49 5459 93100

Fax+49 5459 931050

About us

Founded in 1850, the Polyvlies Group today has over 500 employees at 5 locations worldwide. In addition to the headquarter in the north west of Germany, the company is also represented in Saxony, France, Slovakia and in the Us, North Carolina.

Polyvlies develops, produces and finishes technical nonwovens made out of synthetic, natural and/or mineral fibers. That offers a vast number of variations and processing possibilities. Because of incorporating the most modern technology Polyvlies is capable of producing technical textiles with a maximum working width of 6 metres and weights from 80 to 4 000 g/m². The focus on customer orientation and joint application-specific developments have resulted in a range of more than 6 000 products that are produced from a number of different raw materials in an order-specific production procedure for various sectors (e.g. automotive, home textiles and geotextiles etc.).

Our product groups

Our application areas / Solutions

- Textiles for landscaping

- Landfill textiles

- Landscaping

- Carpets

- Subsoil reinforcement

- Hoses und textile-reinforced pipes

- Antistatic textiles

- Soil covering material for horticulture and agriculture

- Filters / filtration

- Textile drainage systems

- Textile irrigation systems

- Earthworks and road construction

- Water engineering

- Pipe renovation methods based on textile hoses

- River-bank and coast reinforcement

- Drainage systems

- Carpets

- Exterior and interior textile noise barrier walls

- Sound, heat and cold insulations

- Substrates for coating, film lamination and gumming

- Automobiles

- Textile roofings and roofing sheets

- Textiles for the painting and coating sector

More about us

Special Interests

Keywords

- Vliese

- Technische Vliesstoffe

- Technische Textilien

- Vliesstoffe

- Nadelvliese

Our Products

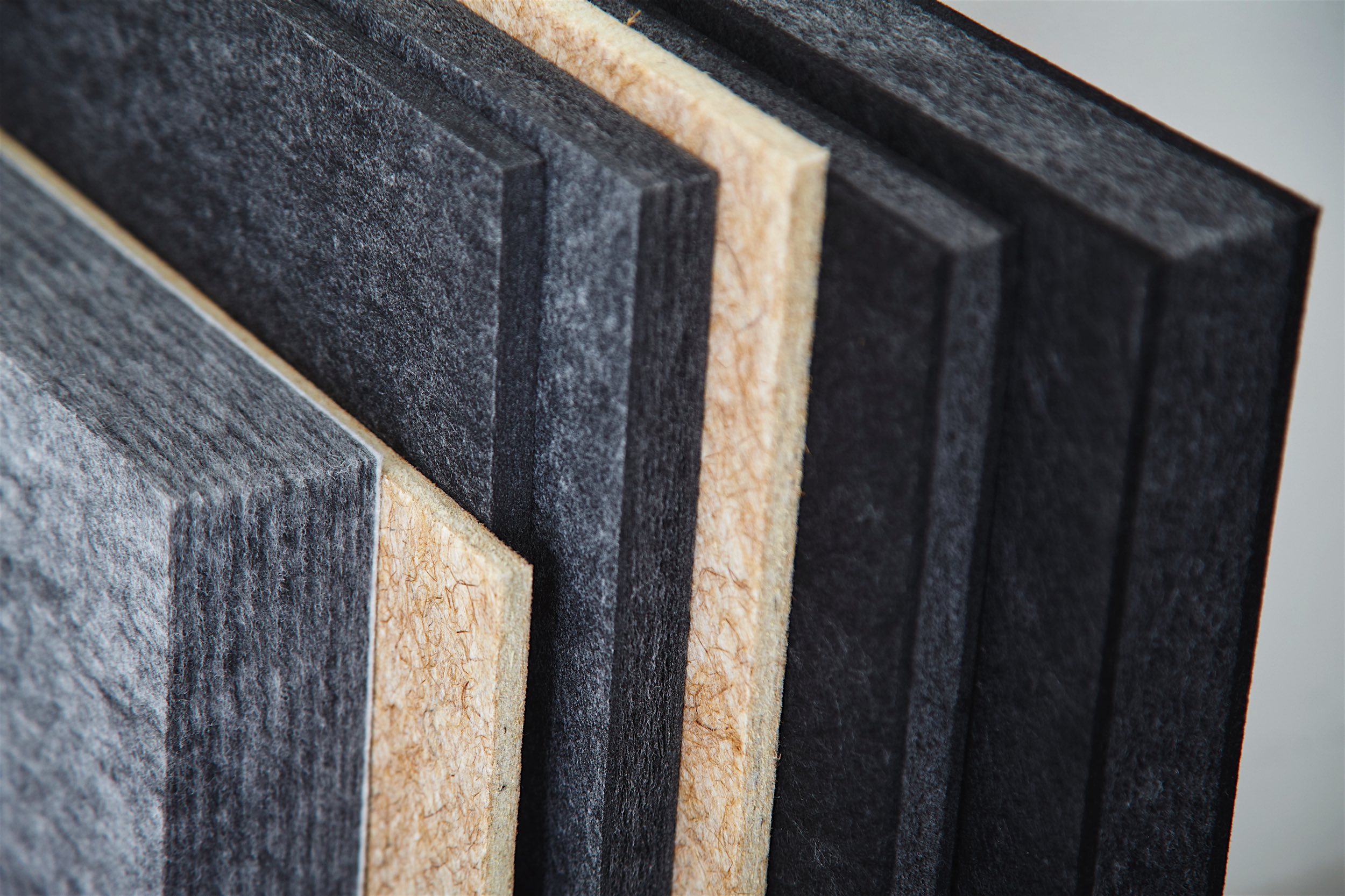

Fonatex®

Let our sound solutions optimize your private and commercial environment

Under the brand Fonatex, we bundle our sound absorption panels which can be used, for example, as wall panels, ceiling sails or room dividers. In this way, noise, reverberation or interference in the relevant frequency ranges of room acoustics (approx. 63 to 4.000 Hz) are significantly minimized.

As a standard, we produce Fonatex in a weight range of 1.000 g/m² up to 4.000 g/m² and with a material thickness of 4 mm up to 50 mm. In addition, a variable mix of fiber materials, structures and densities offers the possibility to implement numerous customer-specific requirements.

polypure

New product line especially for filter applications:

\ Polypure Pad for mat filters

\ Polypure Pleat for needled/foldable filter media

\ Polypure Pocket for pocket filter media

\ Polypure Paint for paint separation

These are thermally and/ or mechanically bonded filter media for air filtration, which are mainly made from polyester fibres. Depending on the application, the weight is between 60 g/m² and 600 g/m². Filter classes according to ISO 16890 from ISO Coarse to ISO ePM10 > 50% can be achieved with our filter media.

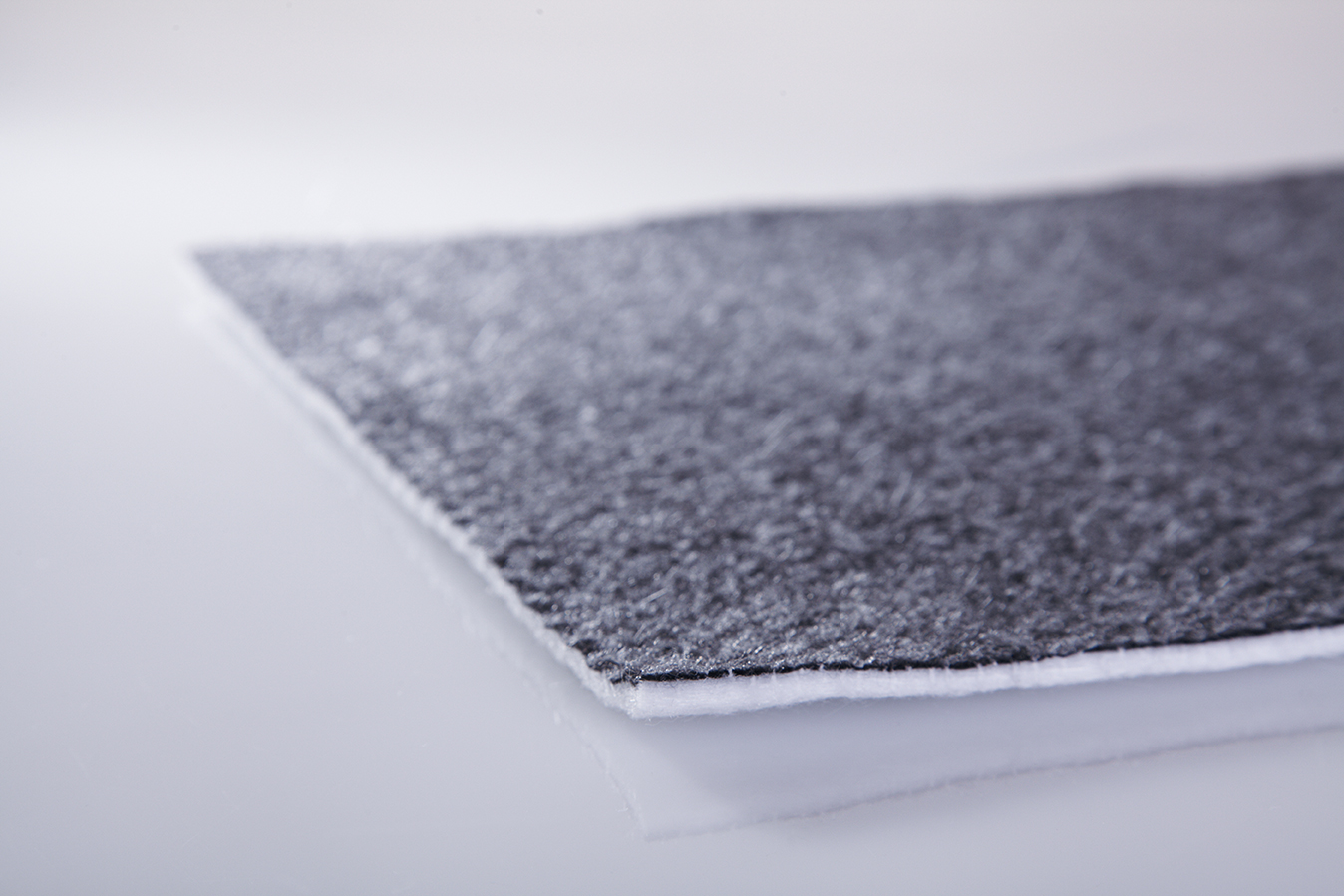

Polytherm®

The segment of acoustically effective fiber absorbers comprises numerous variants of mainly voluminous, primarily thermally bonded nonwovens. With their textile structure and their light weight they offer significant advantages over other sound-absorbing materials.

The benefits lie in the large variability and the easy modification capabilities regarding absorption design, adaption to installation space, shaping and functionalization (e. g. self-adhesive equipment, hydrophobic treatment, edge welding etc.).

SkillCoat™

SkillCoat™ is a nonwoven made out of polypropylene and / or polyester fibers. Because of the special production process SkillCoat™ has a big tensile strength lengthwise. The weight is between 50 and 300 g/m² depending on the specific application.

SkillCoat™ products are particularly suitable as filter media, protection and positioning units of sealing sheets, carrier material for roof sheeting and sealing sheets, impregnated composites or carrier parts for conveyor belts.

Vitratex®

Glass-fiber nonwovens can be made of 100 % glass fibers or in a mixture with other fibers such as polypropylene, polyester or even natural fibers and are consolidated by means of needle-punch technology.

At present, nonwovens with mixtures of glass fibers and synthetic fibers in a weight range from 200 g/m² to 2,500 g/m² are produced.