Picanol N.V.

Discover more from us

About us

About Picanol

For more than eighty years, Picanol has played a pioneering role in the global textile industry and it is currently the world’s leading weaving machine manufacturer. Picanol develops, manufactures, and sells high-tech weaving machines based on airjet and rapier technology. Picanol offers upgrade kits, spare parts, training, troubleshooting services, and also digital services for its weaving machines through the PicConnect platform. Picanol has its headquarters in Ieper (Belgium) and it employs more than 1,200 people worldwide. Picanol is part of Picanol Group, a business unit of Tessenderlo Group (Euronext: TESB).

Our product groups

- Technology and Processes

More about us

Special Interests

Keywords

- rapier

- Agrotextiles

- Airjet

- Weaving

- Filter

Our Products

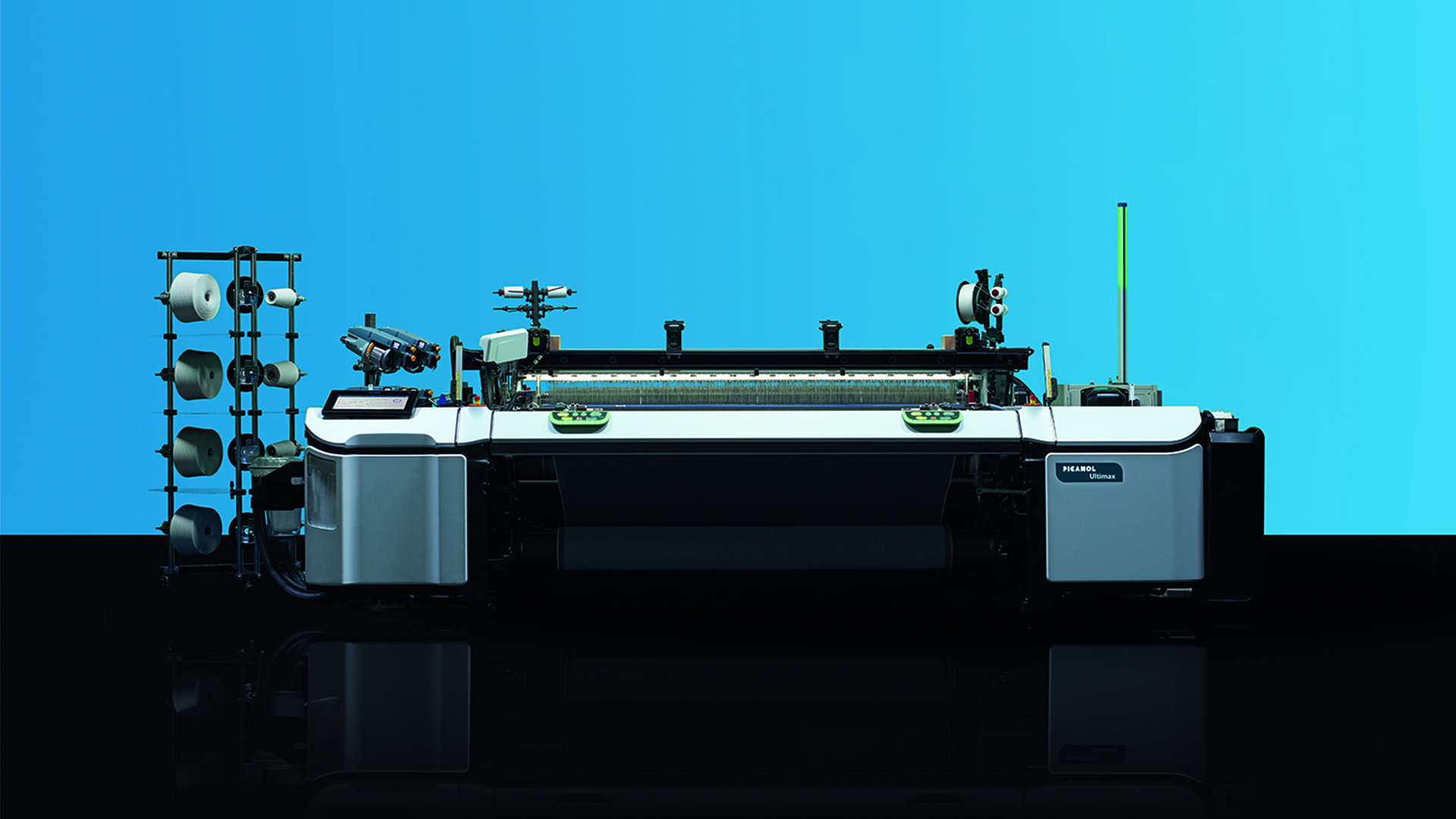

Ultimax

Ultimax

Are you ready for the ultimate weaving experience?

When designing the new Ultimax rapier machine, we focused on the following three aspects:

- Ultimate performance and high-quality output

- Readiness for the sustainability requirements of tomorrow

- The greatest ease of use, thanks to a maximum level of digitization,

based on fully integrated sensors in almost every part of the machine

This means that Ultimax is - more than ever - a machine developed by design

with our four design principles in mind: Sustainability Inside, Driven by Data,

Smart Performance, and Intuitive Control. Thanks to the high level of

digitization and enabled by our digital platform PicConnect, the monitoring of

both individual machines, as well as the entire weaving mill, will become much

easier than before and will give you unprecedented control.

To realize this groundbreaking weaving machine, both our experienced engineers and a new generation of young engineers came together to mix fresh ideas with years of experience. And armed with the latest design techniques, they critically examined and questioned each and every element of the machine.

The result is a focused and razor-sharp machine that is ready to go with audacious speed, precisely reacting to your slightest touch or setting, and faultlessly bringing you top-quality output - both now and in the future.

Even our classic exterior design has been radically disrupted to make it clear from the outside how cutting edge the Ultimax is on the inside.

We can truly state that Ultimax is a revolutionary rapier platform, based on which we and our customers will be able to cope with the many challenges ahead when it comes to sustainability, digitization, and obviously also realizing maximum performance with minimum use of resources.

The future may be uncertain and changing.

But with Picanol and our new Ultimax by your side,

you can confidently cope with any future challenge.

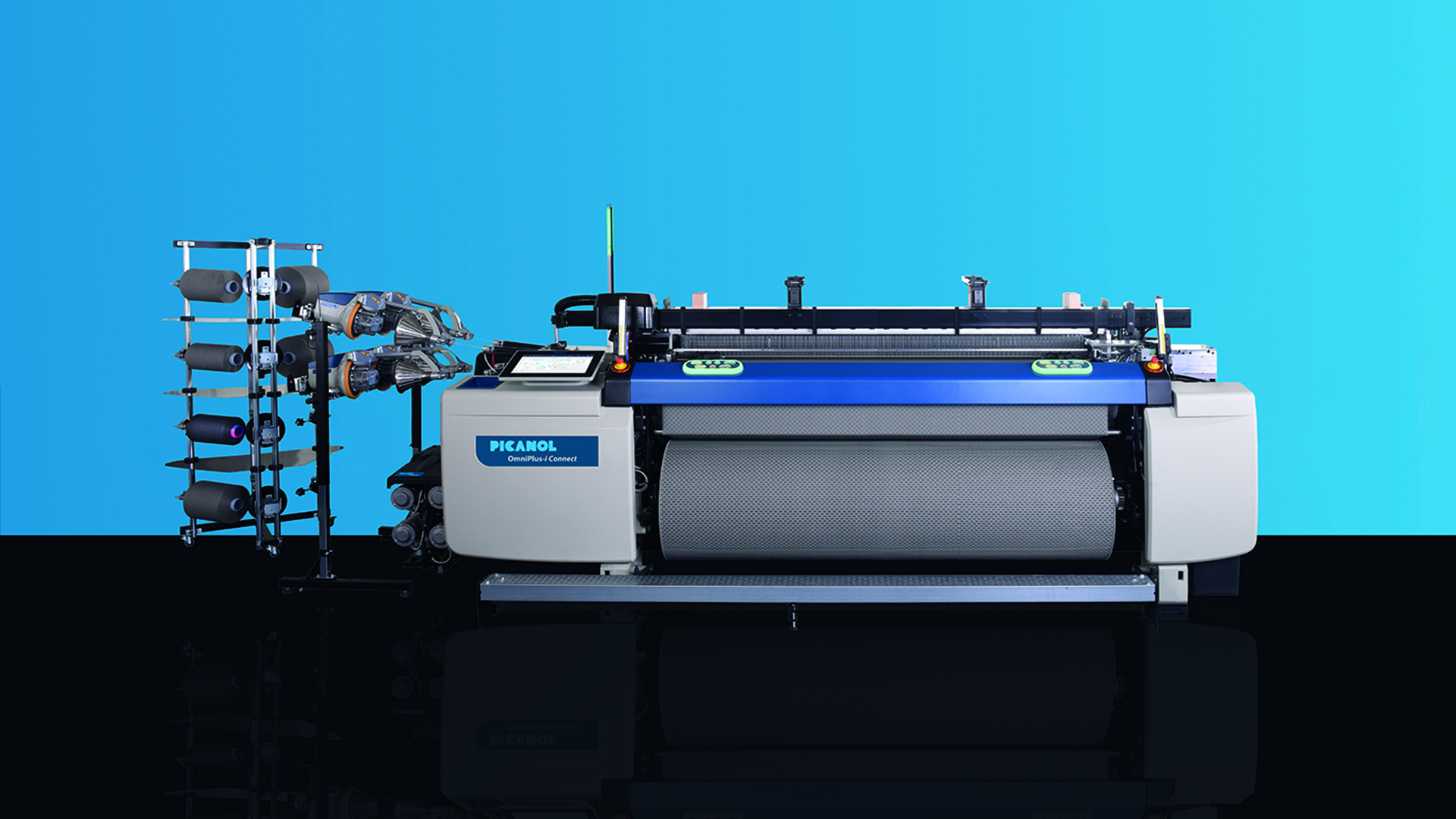

OmniPlus-i Connect

OmniPlus-i Connect The new benchmark in airjet weaving

Building further on nearly 40 years of experience in airjet weaving and over 100,000 airjet machines shipped, the new OmniPlus-i Connect combines this rich heritage with a clear vision of the future.

At Picanol, we believe that in this fast-changing world of weaving, the needs of weaving mills in general and the expectations of our customers and their operators are evolving rapidly. Our market is nowadays driven by an increasing concern for environmental topics, higher costs, and the lower availability of resources and skills, as well as the digital revolution.

That is why the OmniPlus-i Connect has been built around our four leading design principles.

Smart Performance

Picanol machines have always been built for maximum performance, and they always will be. Smart performance focuses on ensuring the highest industrial speeds in the market even under difficult conditions.

With the new OmniPlus-i Connect we achieve this thanks to a completely new reed motion: more insertion time permits the smooth handling of even less-than-perfect yarns.

Sustainability Inside

The further reduction of energy consumption is not an optional extra – it has to be embedded in the machine design. With its modified relay nozzle distance, the new OmniPlus-i Connect offers more stable insertion and consequently new possibilities for achieving a further reduction in energy consumption, even by automated algorithms. In other words, sustainability is inside.

Driven by Data

Picanol has pioneered the digitization of weaving machines for many decades now. SmartShed – the fully electronically controlled shedding motion incorporated in the new OmniPlus-i Connect – is a logical next step in this evolution. This together with an abundant use of sensors generates lots of data that fuel real-time optimization algorithms and promise even more gains in productivity when combined with other data. This even applies to data from other machines. Therefore, weaving with Picanol becomes truly driven by data.

Intuitive Control

Picanol machines are always designed to be as user-friendly as possible. Thanks to the BlueTouch display with its complete newly designed user interface, the Smart signal lights and the implementation of Access control, the highest level of intuitive control has been incorporated in the machine design of the OmniPlus-i Connect.

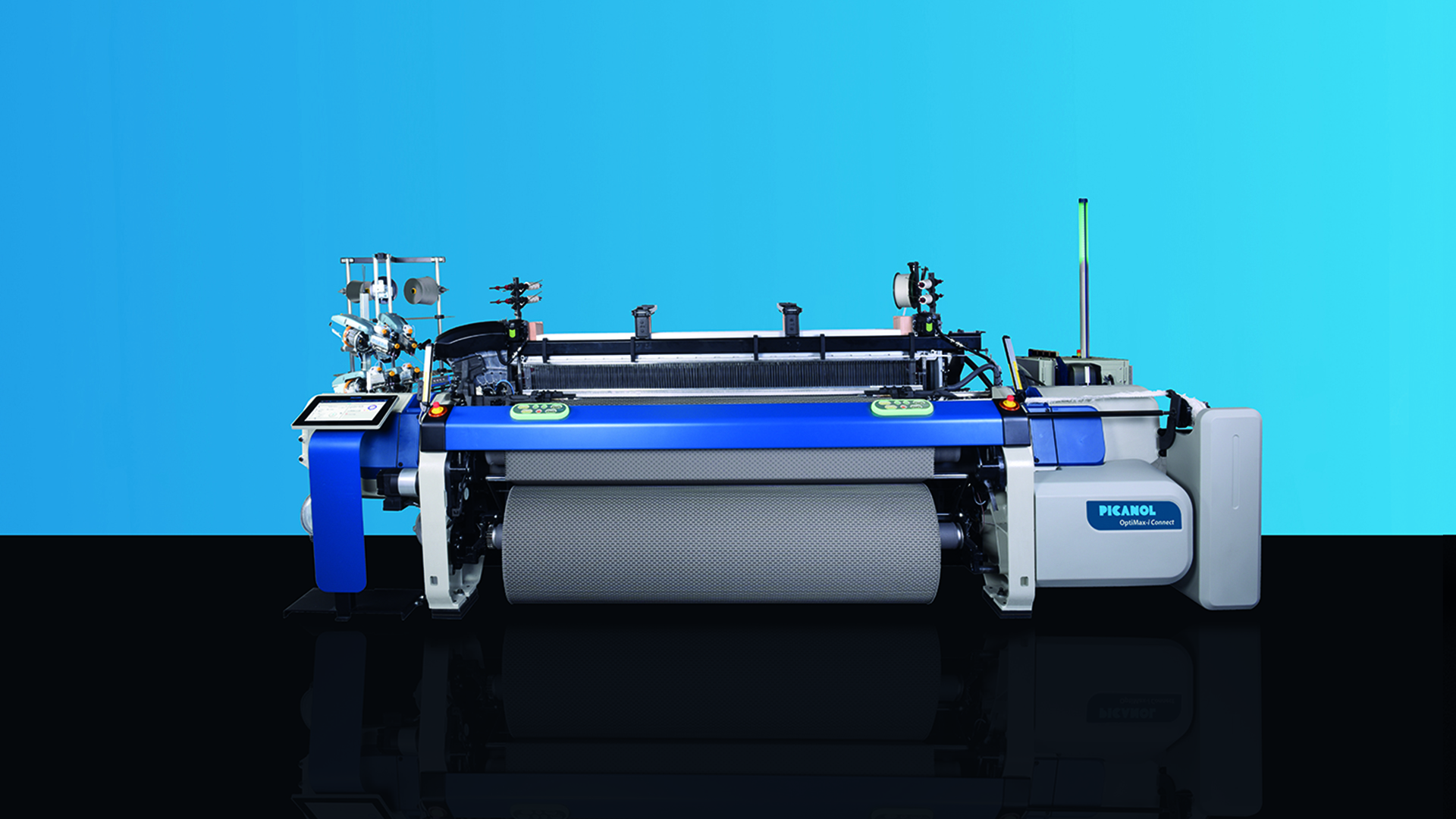

OptiMax-i Connect

OptiMax-i Connect The new benchmark in rapier weaving

If versatile and productive weaving driven by digitization and Industry 4.0 is your objective, you can now be sure to experience real added value with the unique, future-oriented OptiMax-i Connect.

The OptiMax-i Connect offers you all the possibilities for being at the top in your market. Ready for every new opportunity.

Our market is nowadays driven by an increasing concern for environmental topics, higher costs, and the lower availability of resources and skills, as well as the digital revolution. That is why the OptiMax-i Connect has been built around our four leading design principles.

Smart Performance

Picanol machines have always been built for maximum performance, and they always will be. Smart performance not only focuses on speed but also on top quality and versatility.

With the OptiMax-i Connect, smart performance is guaranteed by the robust machine structure combined with the proven shed geometry and the most suitable rapier system for any application.

Sustainability Inside

Minimizing the energy consumption cannot be an optional extra - it has to be embedded in the machine design. To this end, the Sumo drive concept has become even more energy-efficient. Sustainability inside is not only about energy but also about resources. EcoFill and ERGO are just a few features on the OptiMax-i Connect that will help you optimize the use of your most valuable materials.

Driven by Data

Picanol has pioneered the digitization of weaving machines for many decades now. The BlueBox is our reliable electronic platform, ready for Industry 4.0. With the BlueTouch display, all data is gathered and visualized in overview dashboards. The data is ready to be used for further optimization of the machine performance or to be exchanged – be it with data from other machines or data available in the cloud. Therefore, weaving with Picanol becomes truly driven by data.

Intuitive Control

Picanol machines are always designed to be as user-friendly as possible. Thanks to the BlueTouch display with its complete newly designed user interface, the Smart signal lights and the implementation of Access control, the highest level of intuitive control has been incorporated in the machine design of the OptiMax-i Connect.

OmniPlus-i TC Connect

OmniPlus-i TC Connect

- Improved insertion thanks to combination of new generation of sley drive cams and relay nozzle pitch of 60 mm

- Maximum speed 1000 rpm

- Redesigned SUMO drive concept

- BlueBox electronic platform

- Smart signal lights

- BlueTouch 15.6“ touchscreen display

- Robust machine frame structure with low vibration level

- Easy width adjustments

- Standard with asymmetrical as well as symmetrical width adjustment

- Extra reinforced harness frames with DRC30 connection

PicConnect

Welcome to the era of intuitive weaving

With PicConnect, Picanol is centralizing its digital tools and services in one new fully digital platform, offering a wide range of features from industrial IoT to service-related applications.

PicConnect enables you to quickly react to changes in the weaving room, and it will have an immediate impact on the performance of the weaving machines. It will not only change how you work with your machines but also the way you interact with Picanol. For this reason, Picanol can boldly state that PicConnect is bringing you into the era of intuitive weaving.

Web-based

PicConnect is a web application. The platform can be accessed from the browser of any device connected to the internet, even the display (PD15) of our weaving machines.

Cloud-based

PicConnect is cloud-based. The latest applications and updates are automatically available in your own secure environment.

Connectivity

To leverage the full extent of possibilities the platform offers, machines can be connected using an internet connection. All machines with a BlueBox platform can be connected.