Maschinenfabrik Herbert Meyer GmbH

Address

Maschinenfabrik Herbert Meyer GmbH

Herbert-Meyer-Straße 1

92444 Rötz

Germany

Telephone+49 9976 2080

Fax+49 9976 1510

Discover more from us

About us

Since the company MEYER was founded in 1949, we have been one of the most important manufacturers of special machines for bonding, coating, pressing and molding.

This is also expressed by our slogan: Ideas that bond.

For several decades, Meyer produces innovative machinery such as fusing machines, heating presses, laminating lines and also large molding lines. Our satisfied customers all over the world are taken by our thorough knowledge and our innovative solutions.

Highest quality and delivery reliability are guaranteed with motivated employees as well as by using most modern machines for a high production depth and development tools such as 3D-CAD, CAM, E-CAD and ERP system.

Being a family business led nowadays by the third generation, flexibility is of course an important factor. We are gladly prepared to fulfill our customers’ individual demands and requirements.

Trust in our experience!

We have a very large application sector:

- Laminating of industrial technical textiles, non-wovens, foams, foils.

- Industrial composites: glass–aramid-carbon fibres, honeycombs, fibre reinforced composites

- Filters: activated carbon filters

- Medicals: compressing & calibrating, membrane foils

- PU and other foils

- Coating: pressure sensitive coatings

- Interior and acoustic parts

- Automotive and building industry as well as other technical industries.

The new vacuum lamination technology can be performed on our KFK-V. It canbe used for continuous production of flexible thin film solar cells as well as thin glass solar modules or high tech composites.

Our latest development is the high pressure double belt press KFK-P, which has been designed consequently for highest pressures and high temperatures. This flatbed lines are a real economic alternative to classic steel-belt lines.

You are welcome to visit our competence center in Rötz for

- Innovative solutions

- Consulting of machine concepts

- Selecting the perfect adhesive system

- Complimentary first trials on various machines

Our product groups

Our application areas / Solutions

More about us

Special Interests

Downloads

Keywords

- laminating

- molding

- Kaschieren

- coating

- scattering

Our Products

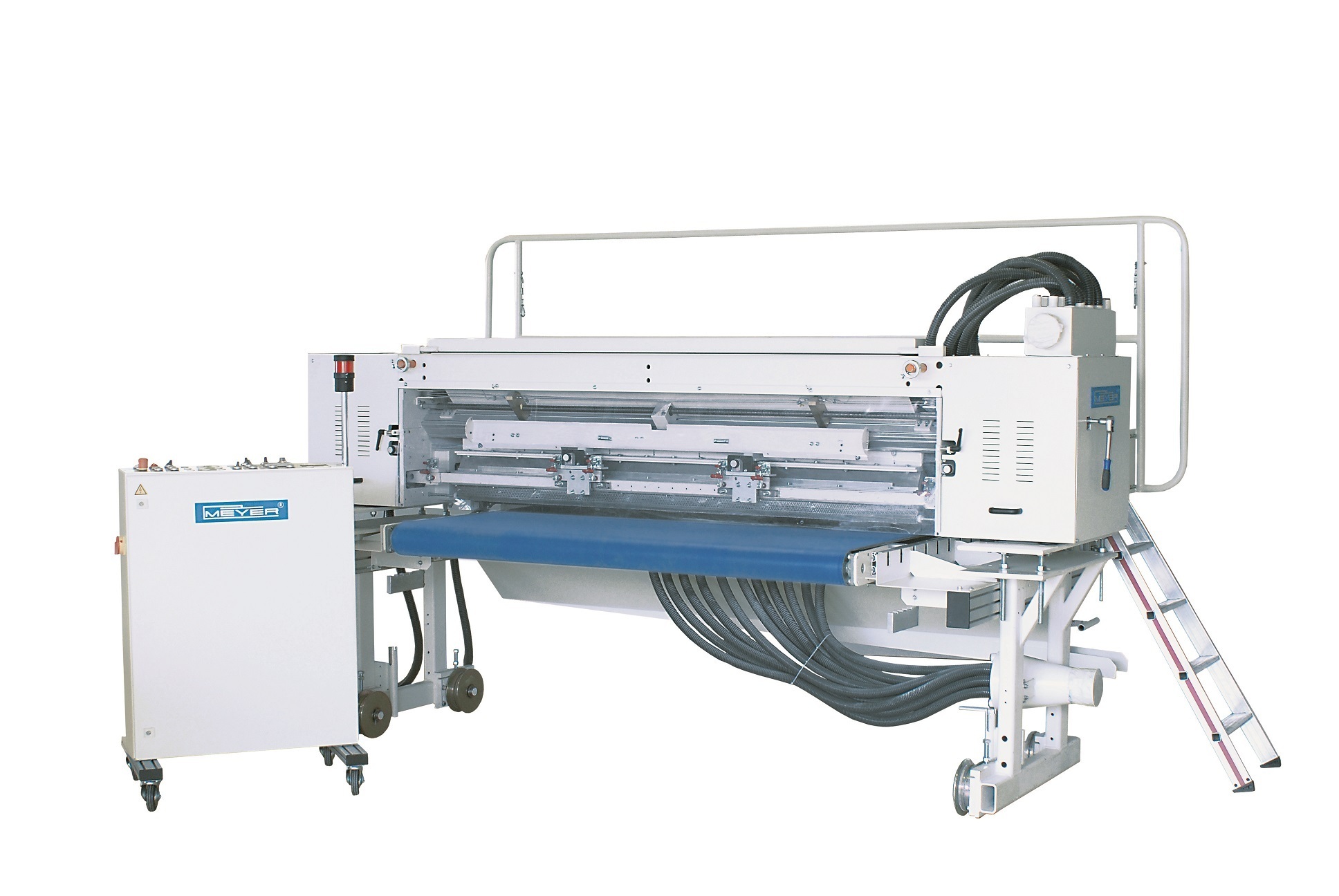

RPS-E2 leather laminating machine

Fusing machine especially designed and optimized for laminating leather

3 temperature zones

pressure rollers with precise gap setting

cooling system inside loading belt

innovative SIEMENS control

PST Powder scatter

for application of powdery material

for thermoplastic adhesive powder or other powdery material

precise and uniform application

flexible and maintenance-friendly

respirable dust extraction system

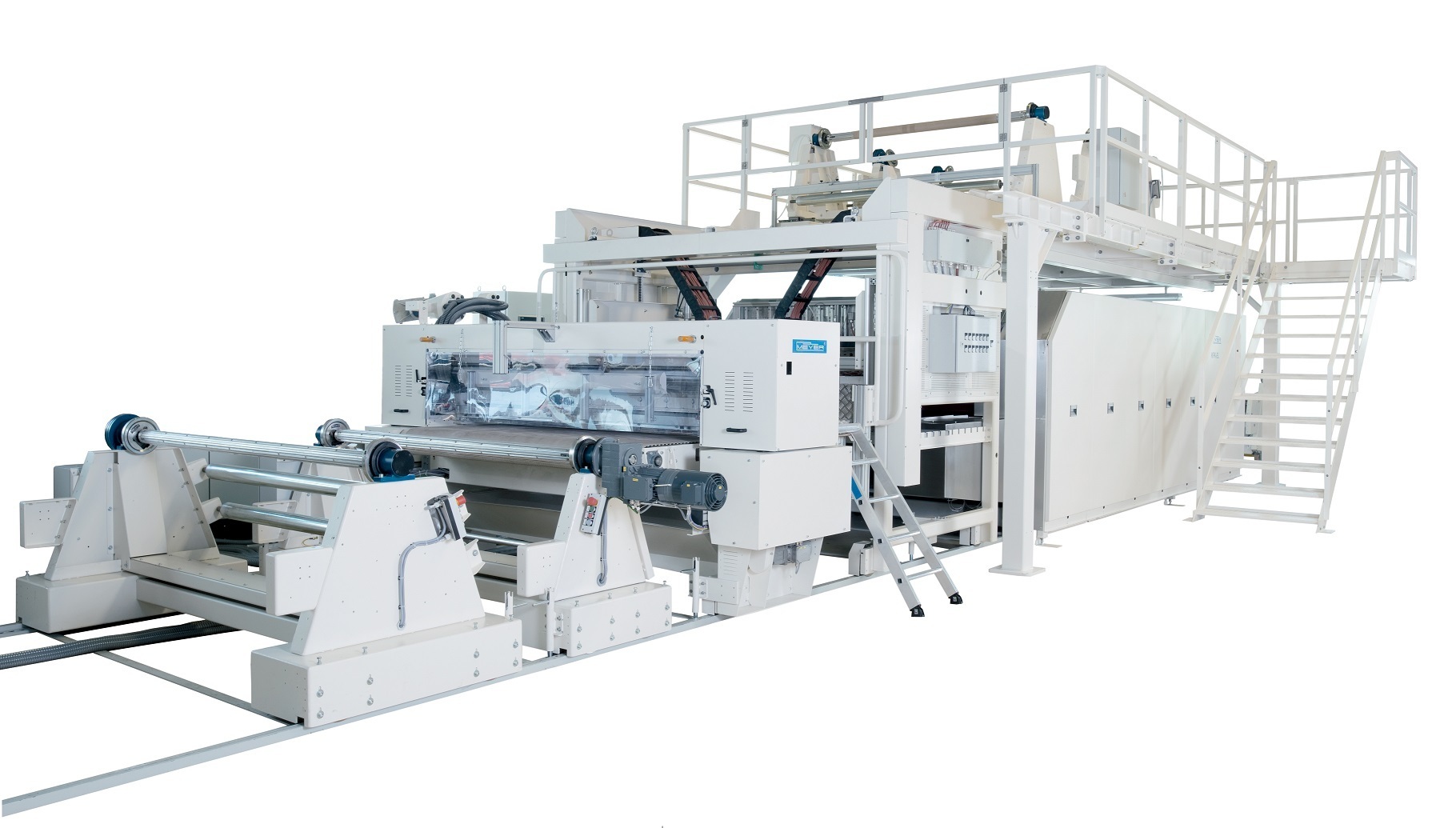

Flatbed laminating machine KFK

Flatbed laminating machines in various designs with respective periphery acc. to customers´requirements

MEYER Flatbed-Laminator-Systems

are double belt presses with integrated contact heating and cooling. The materials that are laminated are heated very gentle. Due to the long heating zone the materials are laminated perfectly with high bonding strength. Right after the heating the materials can be pressed together or calibrated to a set thickness with the pressure rollers. To stabilize this compound the materials a cooled down before they exit the double belt press. With the flat gap between the belts and the precise height adjustment even rigid plates with a thickness of up to 150mm can be laminated.

Process parameters

- Heating time = production speed

- Temperature in heating zone

- Pressure of pressure rollers

- Gap of pressure rollers (level adjustment)

- Height adjustment = gap between belts

- Temperature in cooling zone

Adhesive

Normally thermoplastic adhesives are used when using a Meyer flatbed laminating machine. These adhesives are environmentally friendly, easy to handle and there are special adhesive types for nearly all applications. Also the requirements for recycling, sort purity, fogging, environment and health care are easily achieved with thermoplastic adhesives.

Depending on the application and the requirements also other adhesive systems, like reactive adhesives can be easily combined with Meyer flatbed laminators.

Machine for following apllications:

foil coatings

powder coating

pressure sensitive coating

2- and multilayer laminates

calibrating

thermo-bonding

surface-smoothing

Fusing machines

Fusing machines in various designes for textile and clothing industry

Meyer is one of the leading manufacturers for fusing machines used in the garment industry. In the sector of continuous fusing machines, Meyer offers the suitable machine for every application at different widths. Stacker and loading belts make this large selection complete. Numerous options enable an optimal adaptation to customers‘ requirements.

Molding lines

molding lines for automotive industry

Depending on the application we design machines with different dimensions and press forces, as well as manual simple systems or full automatic molding lines.

Molding lines for

- carpets

- trunk covers

- door panels

- headliner

- parcel shelves