The exhibitors & products at Techtextil 2026 will be available here from mid-January 2026.

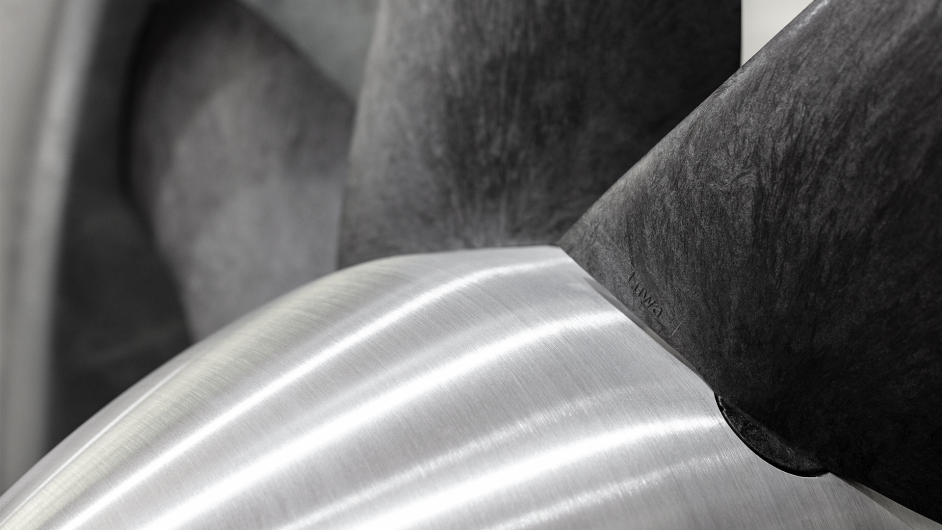

Axial Ventilator B800CF mit Carbon-Schaufeln

Axial Ventilator B800CF mit Carbon-Schaufeln

Beschreibung

Der neue Axial-Ventilator B800CF besteht aus dem sehr leichtes und hochfesten «Hybrid Long-Carbon Fiber-Compound» Material. Im Vergleich zu Aluminiumventilatoren ermöglicht LCF-Material neue Möglichkeiten im Design:

- grössere Schaufeln,

- breitere Sehnenlängen bei niedrigerem Gewicht und

- niedrigeren mechanischer Beanspruchungen und dadurch

- mehr nutzbare aerodynamische Fläche an der Schaufel.

Vorteile:

- Verbesserte Aerodynamik/Effizienz

- Beste Leistung & Wirkungsgrad in den typischen P/V-Arbeitsbereichen für Industrieventilatoren in Textilklimaanlagen

- Designt für einen breiteren Arbeitsbereich – mit gleichbleibender hohen Energieeffizienz auch bei wechselnden Betriebs- und Druckverhältnissen (z.B. Zustand und Alterung der Filtermedien, wechselnde Anzahl laufender Maschinen, etc.)

- Um die Effizienz bestehender Systeme zu erhöhen, kann der B800CF bei den meisten Luwa Axial-Ventilatoren nachgerüstet werden

Erhöhte Leistung:

Das Laufrad mit seinen charakteristischen sichelförmigen Schaufeln ist für optimale aerodynamische Leistung und effizienten Betrieb ausgelegt. Die Verwendung hochwertiger Materialien und moderner Produktionsmethoden ermöglicht die einzigartige Form der Schaufeln - ein Faktor, der wesentlich zu der hervorragenden Leistung des Axial-Ventilators mit

Carbonschaufeln beiträgt. Die Vorteile des Luwa Axial-Ventilators der Serie B800CF sind ein geringerer Stromverbrauch, eine höhere Ventilatorleistung, ein geringeres Gewicht und ein niedrigerer Geräuschpegel. Im Vergleich zum aktuellen Luwa Axial-Ventilator B600 mit Aluminiumschaufeln, liegt die Effizienz deutlich höher.