Keli New Materials Co., Ltd.

Address

Keli New Materials Co., Ltd.

Zhejiang Tongxiang

No. 571, Tongsheng Road, Economy Develop. Zone

314505

China

Telephone+86 573 8833 3799

Discover more from us

About us

Keli New Materials Co., Ltd. was founded in 2008 located at No. 571,Tongsheng Road, Economic Development Zone Tongxiang City, Zhejiang Province. It is a manufacturer specializing in the research, development, production and sales of glass fiber cloth coating products. The company occupies an area of 30,000 square meters and has 4 workshops; the workshop is equipped with 15 glass fiber twisting machines; 2 silicone coating machines; 16 PTFE coating machines. The coating categories cover PTFE, silicone, PU, acrylic, graphite, etc. The company’s main product "fire-resistant and high-temperature glass fiber coated fabric" can be made into conveyor belts, PTFE architectural membranes, mold release fabrics automotive reinforcement fabrics, fire-resistant sunshade curtains (curtain fabrics), silicone fabrics, etc., and the products are widely used in aerospace, automotive, electronics, electrical appliances high-temperature insulation, plastic products, printing, printing and dyeing, clothing, chemical anti-corrosion, thermal insulation, BBQ grilling & oven baking and other fields. The company strictly standardized management work, and has passed ISO9001, ISO14001. In recent years, the company has obtained 17 utility model patents through independent research and development, two of which are German and Australian patent.LY The company will adhere to the tenet of "Integrity, Responsibility, Innovation, Professionalism, and Efficiency", continue to increase research and development efforts, and provide customers with more and better products and services.

Our product groups

- Fibres and Yarns

- Coated Textiles

Downloads

Documents

Keywords

- PTFE coated fiberglass fabric

- Silicone coated fiberglass fabric

- Fiberglass yarn

- PU coated fiberglass fabric

- PTFE architectural membrance

Our Products

High Temperature Resistant Fiberglass Texturized Yarn

Features:

1. Extreme Heat Resistance

2. Durability and Strength

3. Texturized Surface

4. Versatility

1. Insulation: Use our High Temperature Resistant Fiberglass Texturized Yarn for insulating applications where high heat resistance is required. It is ideal for creating thermal insulation blankets, pads, or jackets that provide effective heat retention and protection.

2. Fire Protection: Incorporate this yarn into fire-resistant fabrics or materials to enhance their heat resistance properties. The yarn's ability to withstand extreme temperatures contributes to the overall fire protection capabilities of the finished products.

3. Gaskets and Seals: Use the yarn in the production of gaskets and seals that require excellent heat resistance. The yarn's strength and durability ensure that the gaskets maintain their shape and functionality, even in high-temperature environments.

4. Protective Clothing and Accessories: Create heat-resistant clothing and accessories using this yarn. It can be used in the production of gloves, aprons, welding blankets, and other personal protective equipment designed to protect against high temperatures and heat-related hazards.

PTFE coated fiberglass fabric

PTFE coated fiberglass fabric is a high-performance material made from fiberglass cloth and coated with PTFE composite material. This material is widely used in various fields due to its excellent properties such as anti-stick, high temperature resistance, and corrosion resistance. The non-stick surface makes it very easy to clean, making it suitable for various food processing, such as baking, toasting, and sandwich making. It can also be used as a coating and insulation material, widely used in industrial equipment such as loading and unloading machines and high-speed belt dryers. Its high strength and flexibility make it an ideal material for making heat-resistant insulation pads, electrical insulators, and bearing pads.

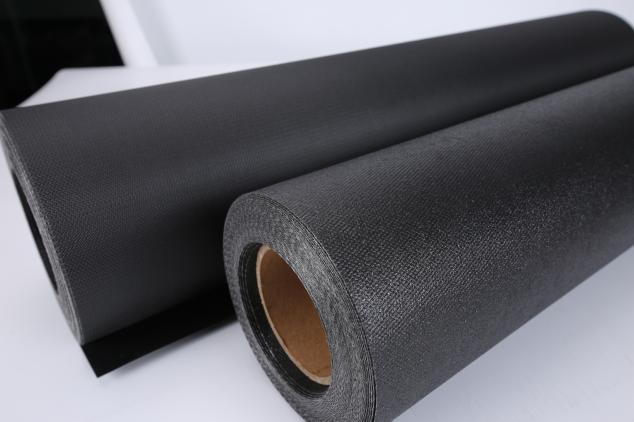

Silicone coated fiberglass fabric

1.High-temperature resistance

2. Corrosion resistance

3. Excellent insulation performance

4. High strength

Applications:

1. Thermal insulation: Silicone glass fabric is commonly used in thermal insulation applications, such as in buildings to reduce energy loss.

2. Automotive industry: In the automotive sector, silicone glass fabric can be used to manufacture engine covers, heat shields, and soundproofing materials, providing high-temperature insulation and noise reduction.

3. Aerospace: Silicone glass fabric finds widespread use in the aerospace industry, where it is utilized for manufacturing thermal protection layers, insulation boards, soundproofing materials, ensuring the stability of spacecraft in extreme conditions.

4. Electronics and Electrical: Due to its excellent insulation properties, silicone glass fabric is used in the electronics and electrical industry for applications that require reliable insulation protection.

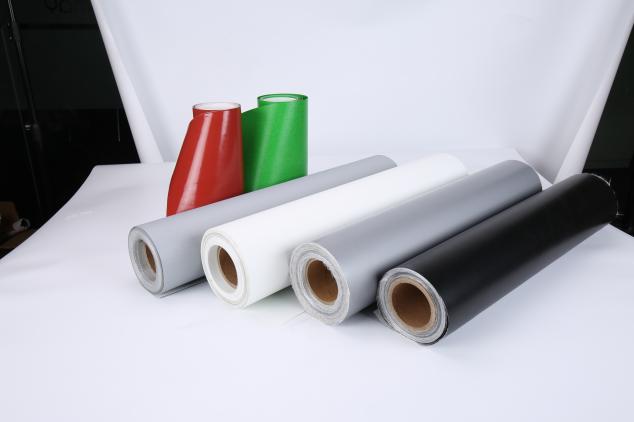

PU coated fiberglass fabric

1. Waterproof and Water-Resistant:

It creates a barrier that prevents water from permeating through the fabric. This makes it highly resistant to water and suitable for applications that require protection from moisture, such as rainwear, outdoor gear, and upholstery.

2. Enhanced Durability:

Increases the fabric's strength and resistance to wear and tear. It adds an extra layer of protection, making the fabric more durable and long-lasting.

3. Flexibility and Softness:

Despite the added backing, backed fabric retains its flexibility and softness. This allows for ease of movement and comfort, making it ideal for applications like apparel, bags, and accessories.

4. Resistance to Chemicals and Abrasion:

It offers resistance to chemicals and abrasion, making it suitable for industrial applications and products that require durability in harsh environments.

5. Versatility:

It is versatile in its applications. It is commonly used in a variety of industries, including automotive, marine, outdoor, and upholstery. It can be manufactured in different weights, colors, and textures to meet specific design and functional requirements.

It's important to note that the specific performance and characteristics of PU backed fabric can vary depending on factors such as the quality of the backing, the base fabric, and the lamination process used. Manufacturers may employ different techniques to optimize the desired properties for specific uses.

PTFE architectural membrance

Applications:

Our PTFE architecture membrane for stadiums can be used for retractable roofs, canopies, and façades. It provides optimal shading and weather protection while allowing natural light to illuminate the stadium. Its lightweight and durable nature make it an ideal choice for any large-scale stadium project.

Advantages:

1. Enhanced Visual Appeal: The PTFE coating creates a sleek and sophisticated look, enhancing the overall aesthetic appeal of the stadium.

2. Natural Light Transmittance: The translucent nature of the membrane allows for ample natural light, eliminating the need for excessive artificial lighting and reducing energy consumption.

3. Weather Resistance: With its excellent weatherproof properties, the membrane provides reliable protection against rain, UV rays, and extreme temperatures.

4. Acoustic Performance: The membrane's unique structure helps to absorb and reduce noise, ensuring a quieter and more enjoyable environment for both spectators and athletes.

5. Quick and Easy Installation: The lightweight and flexible nature of the membrane allows for efficient and hassle-free installation, saving time and resources.

Our Contact Persons

Crystal Shen

Marketing/Advertising

Sales Representative/Agent

Lily Zhou

Marketing/Advertising

Sales Representative/Agent

Jennifer Yang

Marketing/Advertising

Sales Representative/Agent