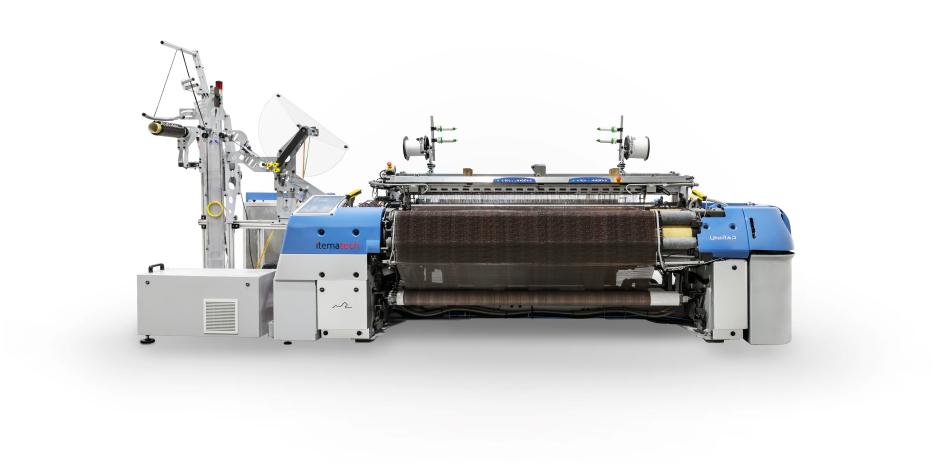

The airjet A9500-2 - the most innovative airjet weaving machine in the market - inspires the curiosity and sparks the interest from real technology buffs and has already amassed important references, especially in medical applications and automotive fabrics.

Looking at specific technical applications, the Itema airjet A9500 provides undeniable benefits, matching unparalleled performances and the highest productivity with superior textile efficiency.

The Itema A9500-2 is pre-set for independent motorized Jacquard with no cardan shaft, allowing to weave specific technical textiles (such as Airbag OPW) with no speed limitations.

When it comes to weaving very high density fabrics, the A9500-2 is customized with dedicated devices to ensure best-in-class results. Key components are reinforced to ensure optimized machine control and reliability whilst Itema patented devices guarantee reduced consumption and superior textile efficiency.

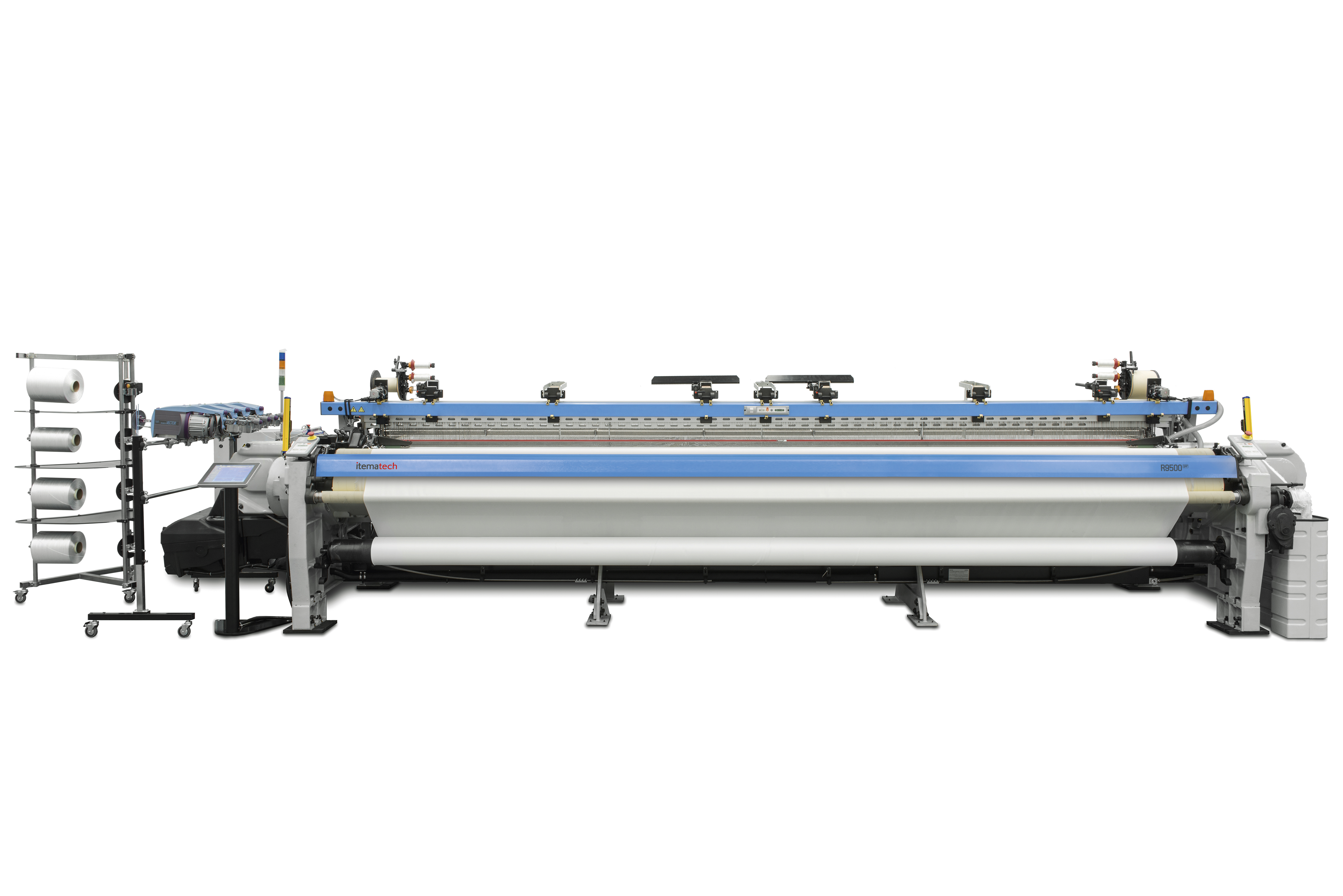

The reinforced whip roller eliminates friction allowing an improved warp tension control and reducing warp stops, whilst the left and right waste selvedgeassures the correct tension of the weft leading to an excellent fabric quality.

Moreover, the longer dwell of the cam sley drive allows a longer weft insertion time, leading to a more efficient weft filling insertion. The Itema patented ELD - Electronic Leno Device, is the ideal solution for leno binding on high speed machines guaranteeing a perfect leno binding whilst significantly reducing operational costs thanks to its innovative design.

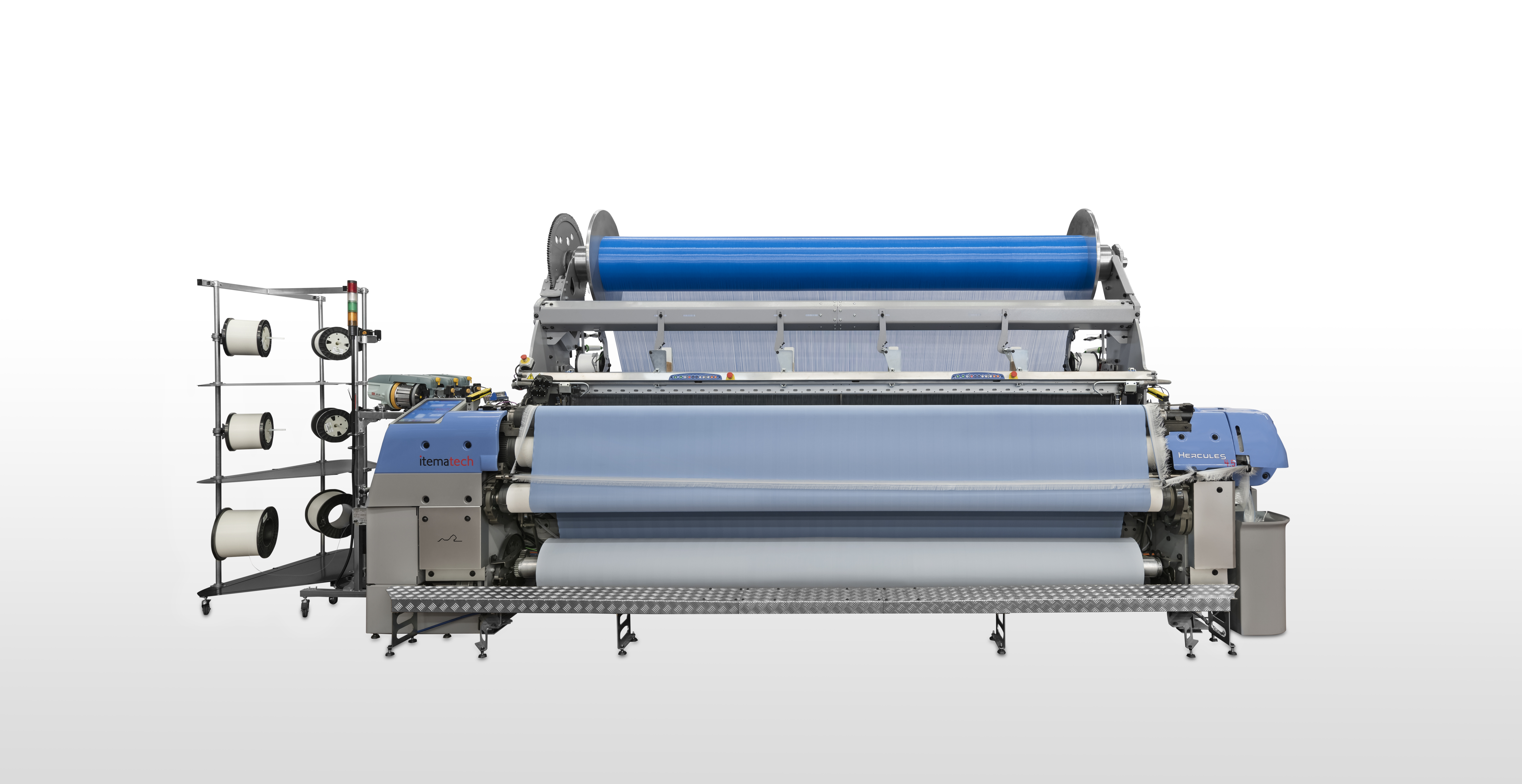

Itema is registering an increasing demand in airjet technology to weave fabrics for the automotive industry. Customers who chose the Itema A9500-2 to weave these type fabrics, reported that in this particular field what makes the Itema airjet extremely successful is again the longer dwell of the cam sley drive and, a recent innovation featured on A9500-2, the double tandem nozzles which allow to weave even the most coarse yarns at high speed.

Parachute fabrics is another main application for airjet technology, and the Itema A9500-2 exceeds weaver’s expectations with its elastic whip roller, a dedicated device for warp tension compensation. The double pick insertion ensures to weaving ripstop and, furthermore, the Polito nozzle guarantees high speed weft insertion and ensures unparalleled productivity.

Best-in-Class Shed Geometry

Optimal heald frames position guaranteeing higher speed and longer life cycle for heddles and harness frames. The optimized beating stroke is ideal to weave the widest range of fabrics ensuring perfect fabric quality

2. BLC - Brush Lycra Clamp Nozzle

Dedicated solution to weave elastic weft yarns ensuring superior fabric quality and reliability, ideal for medical applications (i.e. gauze)

3. Low Blow Single Hole Relay Nozzles

New generation of nozzles to provide lower air consumption and requiring lower maintenance

4. Multiple Selvedge Formation Options

In addition to mechanical tuckers, melting devices and air tuckers are available; for cut and full-width reed, both side and central tuckers are provided, reducing style change set up operations

5. ELD - Electronic Leno Device

Patented solution for leno binding to ensure no speed limitations, higher performances and reduced maintenance

6. Multiple options of Back-Rest Roller

- Reinforced Back-Rest Roller

eliminating friction to allow an improved warp tension control

ideal for warp tension compensation

7. Double Tandem Nozzles

Allowing to weave even the most coarse yarns at high speed

8. New Sley Cam Profile

- Longer weft insertion time due to longer dwell

- Reduced air-consumption

9. iREED®

Patented device to lower air consumption when weaving coarse yarns in narrow width