Hofer Textilveredelungs GmbH

Hofer Textilveredelungs GmbH

Leon-Gonczarowski-Str. 1

95032 Hof

Germany

Telephone+49 9281 750333

Fax+49 9281 750237

About us

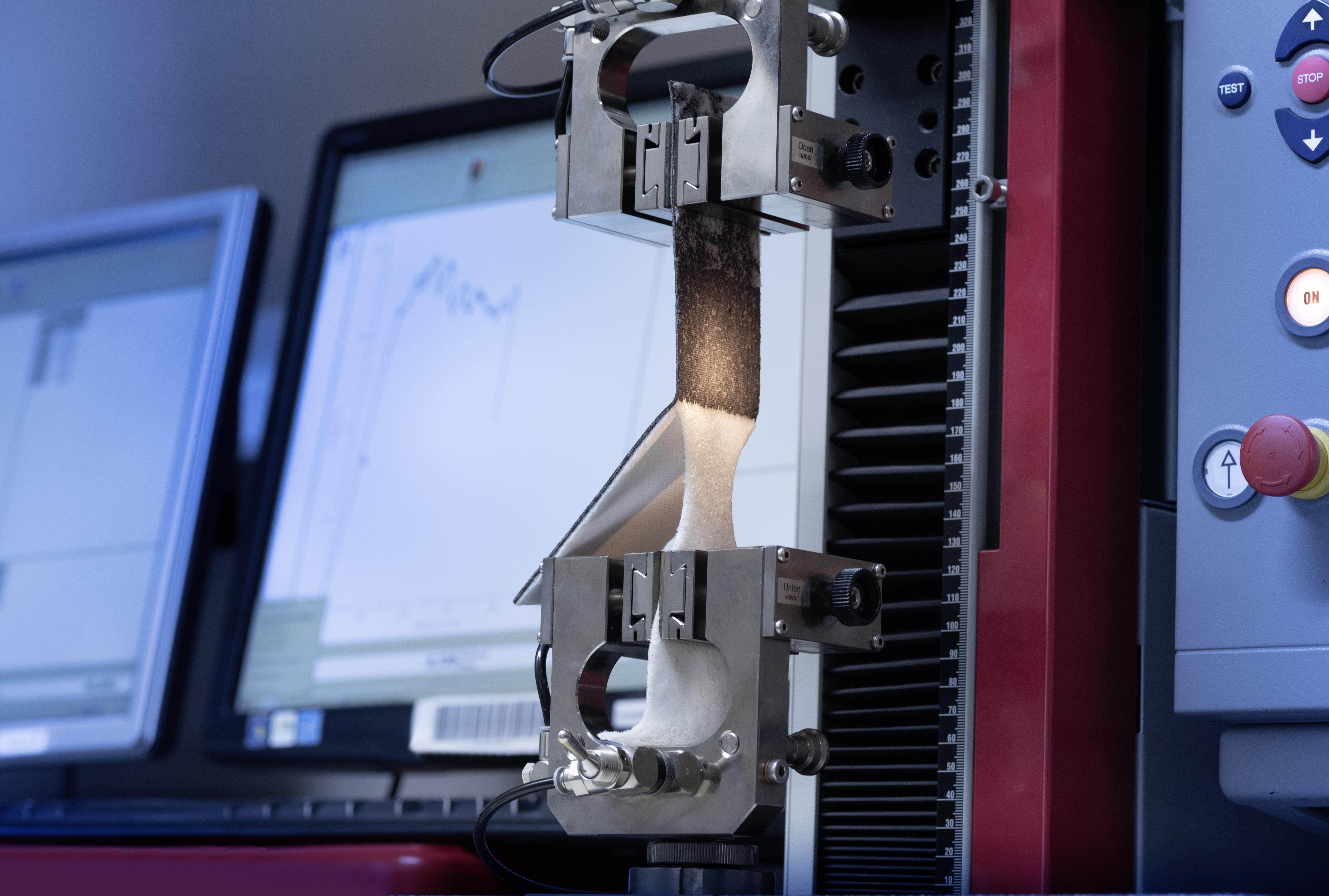

The Hofer Textilveredelungs GmbH based in Hof/Saale finishes high-quality textile surfaces. Our core competence is the manufacture of multilayer compound systems by means of flame laminating of foams. We take on the final inspection for customers and make up rolls according to their specifications. Thanks to the vast stocks we hold on call for our customers we can also offer an extremely capable process of direct dispatch to the production plants. Our EN ISO 9001: 2015 quality and 14001: 2015 environment management system underlies all processes within the company. Ultramodern laboratory equipment, ongoing process optimization based on IATF 16949 and a fully integrated BDE/ERP system provide the requisite transparency, ensure trackability and offer maximum planning security.

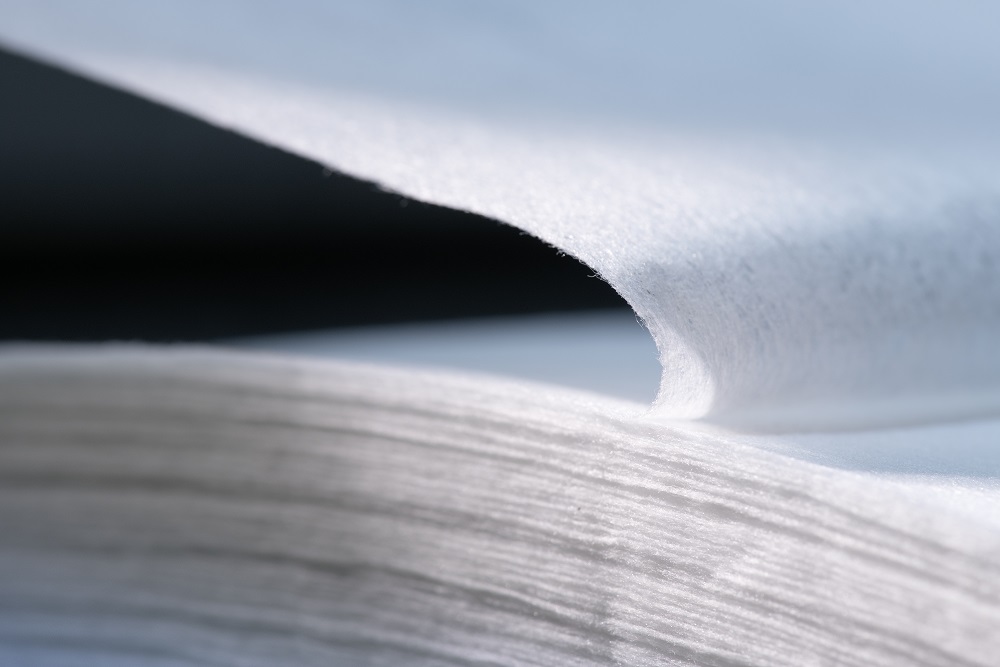

We possess high performance, modern flame laminating machines in widths up to 300 cm.

We work with a vast range of different substrates in roll form and manufacture tri-laminates of up to 20 mm in thickness in one work cycle.

Our continuous processes are configured for a laminating process with very little downtime and thus minimise our customer's reject rate costs.

During the product development phase we and our customers discuss for example, whether to effect a distorsion correction during the laminating process. This may depend on the decorative design that has been stipulated.

Inline thickness measurements are likewise standard, as well as a camera-based inspection for irregularities in backside lamination.

We employ our material inspection machines to visually check the laminated rolls for defined error patterns and mark these according to customer specifications.

All quality-relevant data is stored in our fully integrated data acquisition and enterprise resource planning system for maximum transparency and trackability.

An electronic distorsion measurement of the laminated composite can be effected on every inspection machine and documents the required quality for our customers.

The customer-specific assembling of roll lengths, labelling and sampling process likewise belongs to the scope of activities performed at this process stage.

A barcode system is used to store, pick and despatch the finished goods as packed individual rolls, shrink wrap pallets or A-frames.

Our product groups

- Research, Development, Education, Consulting

- Technology and Processes

Keywords

- Flammkaschierung

- Interieur

- Schaumkaschierung

- Lamination

- Kaschierung

Our Products

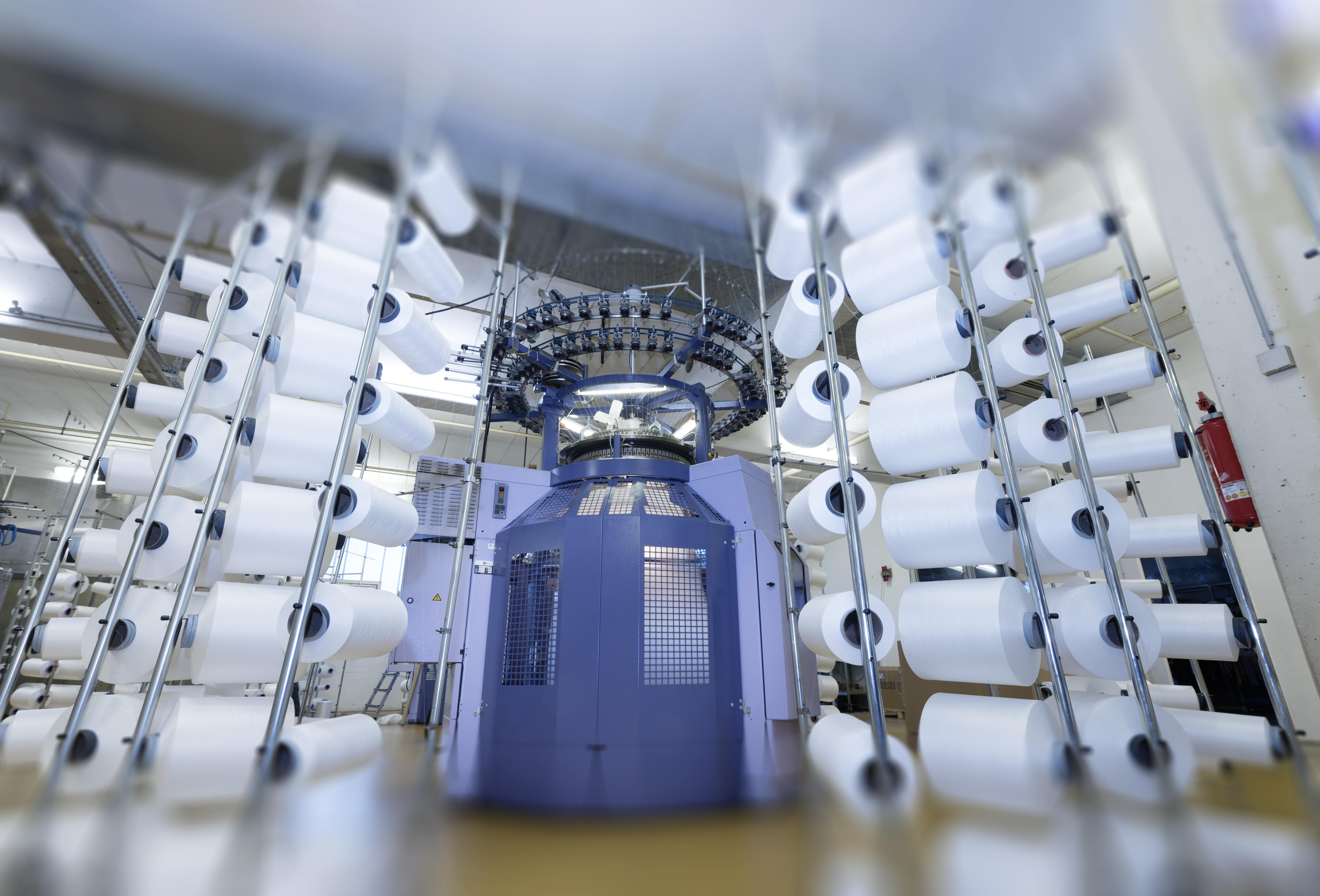

Circular Knitting

Lamination

Subcontracting flame lamination

We are an independent, owner-managed company based in Hof/Saale.

We have been in the business of flame laminating foam materials since 1971 and are now one of the major players in this field in Europe.

Our core competence is "Automotive".

We work in accordance with the quality management standard EN ISO 9001: 2015 and possess a fully integrated data acquisition and enterprise resource planning system

Customer and market focus is at the heart of what we do. We employ the most up to date process and plant technologies and also offer additional service packages.

Flame Lamination