Gebrüder Loepfe AG

Address

Gebrüder Loepfe AG

Kastellstrasse 10

8620 Wetzikon

Switzerland

Telephone+41 43 488 11 11

Fax+41 43 488 11 00

Discover more from us

Follow us on

About us

Loepfe Brothers Ltd. has revolutionized quality control with its unique sensor technology.

Loepfe sensors are included within the production processes for mainly two reasons: quality assurance to reach zero-defect manufacturing for technical textiles and to enable an increase in production efficiency. Our products are successfully in use within various industries such as textile, automotive, electronics, medical, geotextiles, agriculture, architecture, and many more.

Loepfe is the worldwide leading manufacturer and solution partner for electronic online quality assurance systems. Machine manufacturers as well as spinning and weaving mills around the globe use Loepfe technology from Switzerland. They know what to expect: Innovation at top level, quality made in Switzerland.

Our product groups

- Technology and Processes

- Woven Fabrics, Laid Webs, Braidings, Knitted Fabrics

Our application areas / Solutions

Keywords

- Sensortechnologie

- Textile Qualitätskontrolle

- Weaving Solutions

- knots, fluff and filamentation

- quality control

Our Products

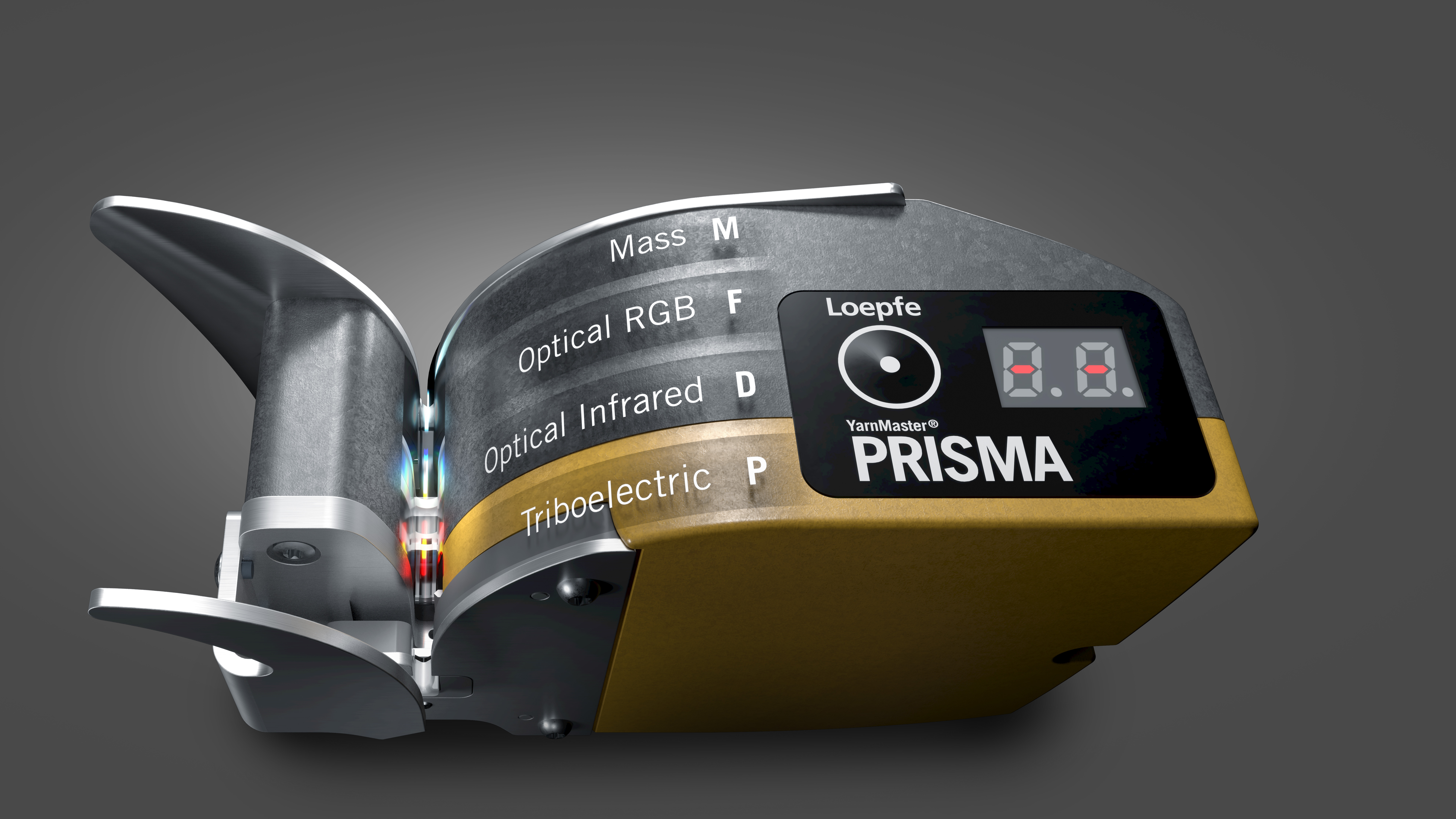

YarnMaster PRISMA

Clever yarn clearing for winding is profitable, efficient, and easy. PRISMA is the solution for spinning mills that need high quality yarns at maximum machine efficiency. With the market's most advanced yarn monitoring system, spinning mills can reduce costs, increase efficiency, and enjoy ease of use.

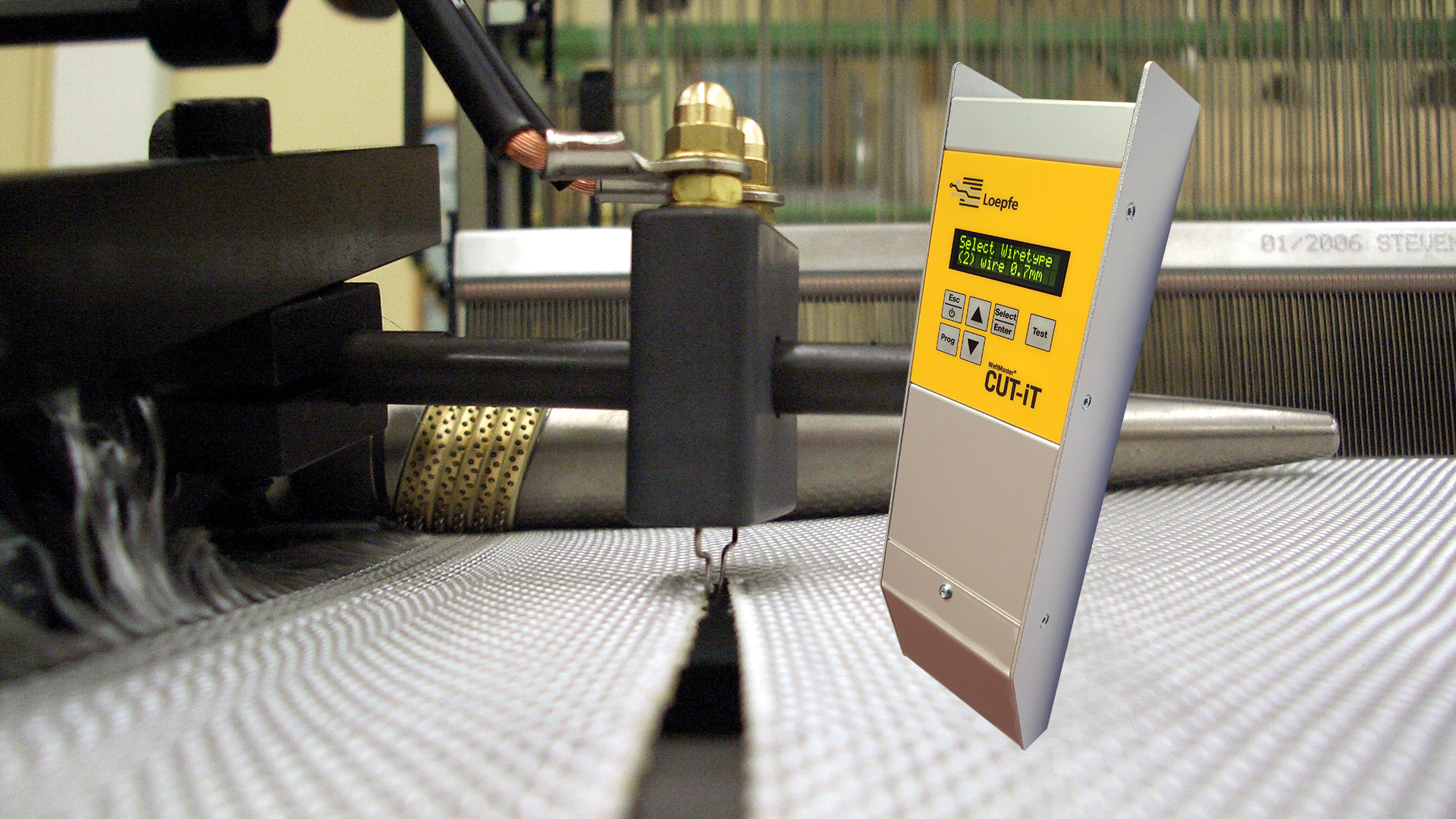

WeftMaster CUT-iT

WeftMaster CUT-iT is the ideal fabric cutter system for thermal cutting from thin and light to dense and heavy synthetic fabrics. It increases the quality of the cutting and reduces style change times.

All over the world, producers of high-end and technical fabrics take no risk and specify CUT-iT to guarantee a top quality and uniform selvedge. Making use of CUT-iT during the fabric production process ensures a quick return on investment for safety-critical products like airbags, tarpaulins or sailcloth. This product is highly demanded in cleantech, medtech, geotextiles, automotive and many more high-tech areas. A top quality and uniform selvedge is highly valued especialy if the yield in post processing is dependent on it.

The CUT-iT control unit offers precisely controllable settings and saves them as a style for later use. This makes style and article changes fast and easy. A single control unit handles multiple cutters, allowing separating fabrics into multiple webs.

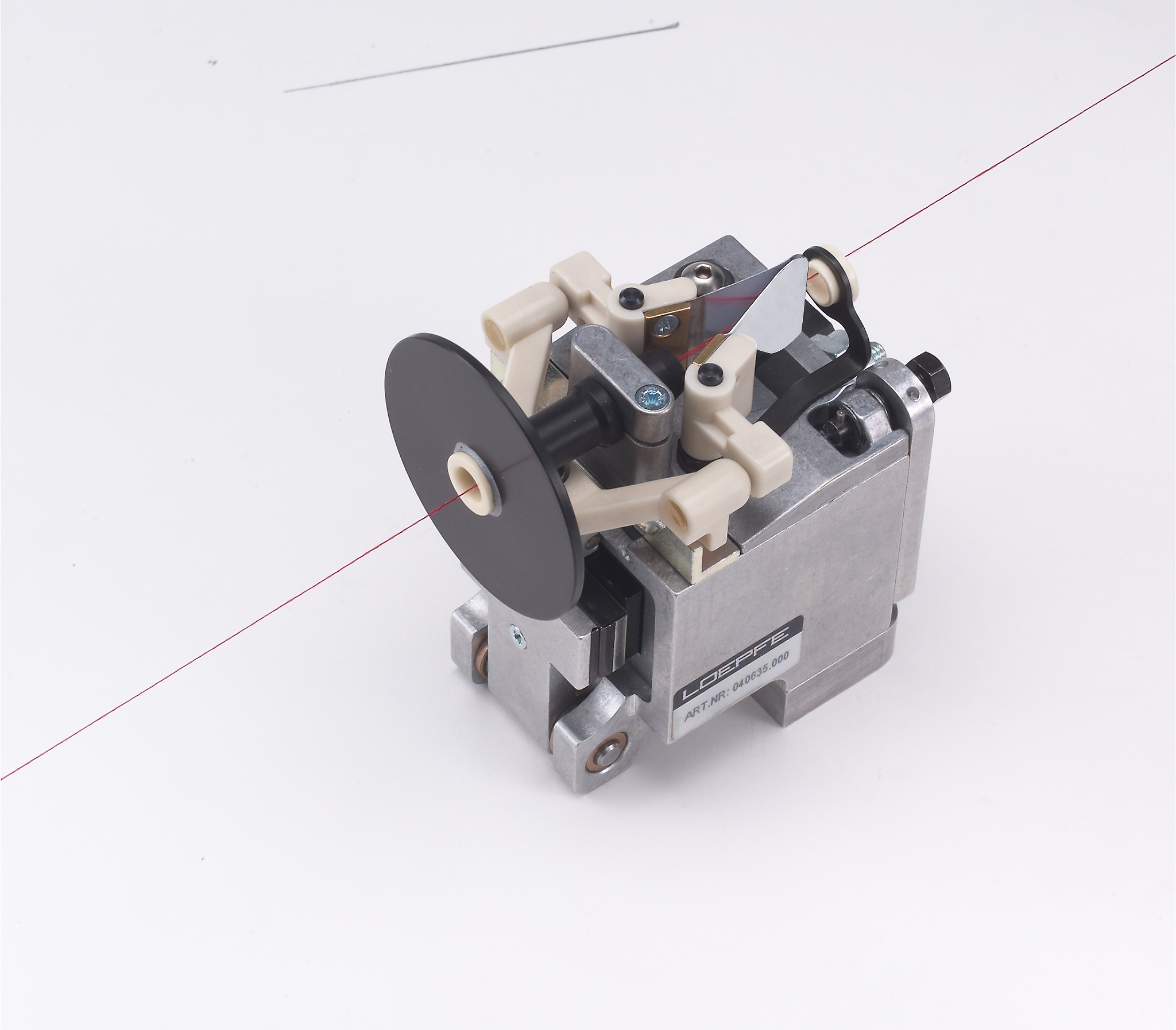

WeftMaster FALCON-i

Removal of the smallest knots, fiber fluff and filament breaks. The FALCON-i sensor from Loepfe in reliably removes the smallest yarn faults during the manufacturing process in the textile industry. Whenever barely recognizable yarn faults could affect the end product, FALCON-i helps you to achieve a quality that exceeds all expectations.

Application:

- large yarn range: 20-3000 dTex

- independent of the yarn color

- Yarn speed up to 30 meters/second

- Conductive materials (carbon fibers)

- monofilament or multifilament yarns

- chemically resistant housing

WeftMaster SFB

The WeftMaster SFB is the perfect solution for controlling optimum weft thread tension for all types of yarns. The device minimizes weft thread breaks and optimizes braking start allowing increased loom speed and achieving higher machine performance and better fabric quality. All brakes also feature reduced yarn abrasion and high wear resistance.

Our Contact Persons

Thomas Sifrig

Sales

Sales Representative/Agent