Fraunhofer-Institut für Techno- und Wirtschaftsmathematik ITWM

TexMath - Simulation of technical textiles

Explore product

TexMath - Simulation of technical textiles

Explore product

TexMath - Simulation of technical textiles

Explore productAddress

Fraunhofer-Institut für Techno- und Wirtschaftsmathematik ITWM

Fraunhofer-Platz 1

67663 Kaiserslautern

Germany

Telephone+49 631 316000

Fax+49 631 316001099

Discover more from us

Follow us on

About us

The Fraunhofer Institute for Industrial Mathematics ITWM in Kaiserslautern is one of the largest and most important research institutes for industrial mathematics worldwide. We see our task in further developing mathematics as a key technology, providing innovative impulses and implementing them practically together with industrial partners.

Computer simulations are an indispensable tool in the design and optimization of products and production processes, services, communication and work processes. Virtual models are increasingly replacing real models. Mathematics plays a decisive role in the design of this virtual world. Not only large companies, but also small and medium-sized enterprises use simulation software to reduce costs. We support companies in this process.

The spectrum of our customers includes, in addition to many other industries, the field of production and application of technical textiles.

Our core competences are in the application areas:

- Flow and material simulation

- Material characterization and testing

- Image processing and quality control

- Optimization

- System analysis, prognosis and control

- High Performance Computing

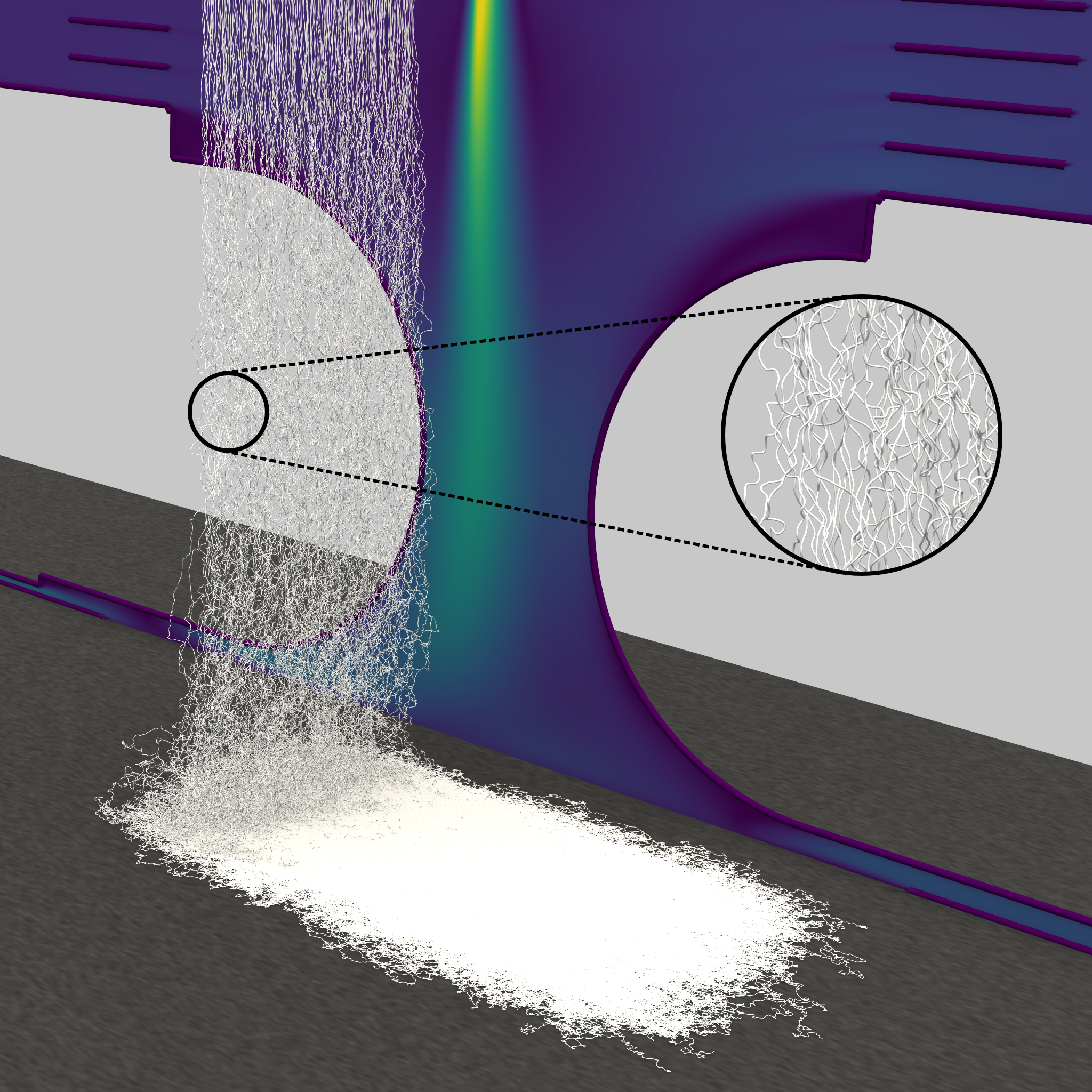

Designing polymer spinning packages for flow dynamics

Melt spinning is the most common process for producing fibres from polymer. The Fraunhofer ITWM uses simulation and optimization methods to support customers in the development, design and improvement of spinning packages.

This simulation-supported analysis provides a glimpse into the spinning package that would otherwise remain hidden. This is the decisive advantage during design, because all flow-dynamic parameters can be quantified directly. Problematic components can be identified and modifications immediately validated.

Machine learning in the textile industry

The trend in the textile industry is towards individualisation in many areas. Consumers are increasingly demanding tailor-made products. However, this requires the digitalization of production, which the ITWM supports with hybrid simulation-based Machine Learning (ML) methods.

The ITWM demonstrates the novel hybrid ML process exemplarily in the optimization of cross-winding machines with regard to a better through-dyeing of the wound yarn bobbins within the scope of the AiF project DensiSpul.

Virtual spinning with VISPI

VISPI is a simulation software that can be used to virtually map and investigate a wide range of spinning processes.

In order to be able to hold their own internationally, German fiber manufacturers are relying on "new developments with high added value in order to be able to distinguish themselves from the mass-produced goods made in Asia". Mechanical engineering, which is assigned to this industry segment, is still strongly rooted in Germany. However, industrial research into product and process innovation on a purely experimental basis is reaching its limits, so that a virtualization trend is increasingly being observed.

Simulations save experiments, allow new insights, enable systematic parameter variations and solve upscaling problems that can lead to serious misinvestments in the transition from laboratory to industrial plant. Due to their complexity, the required simulation capability for spinning processes is currently limited to research institutions, although we as Fraunhofer ITWM also play a leading role in a worldwide comparison.

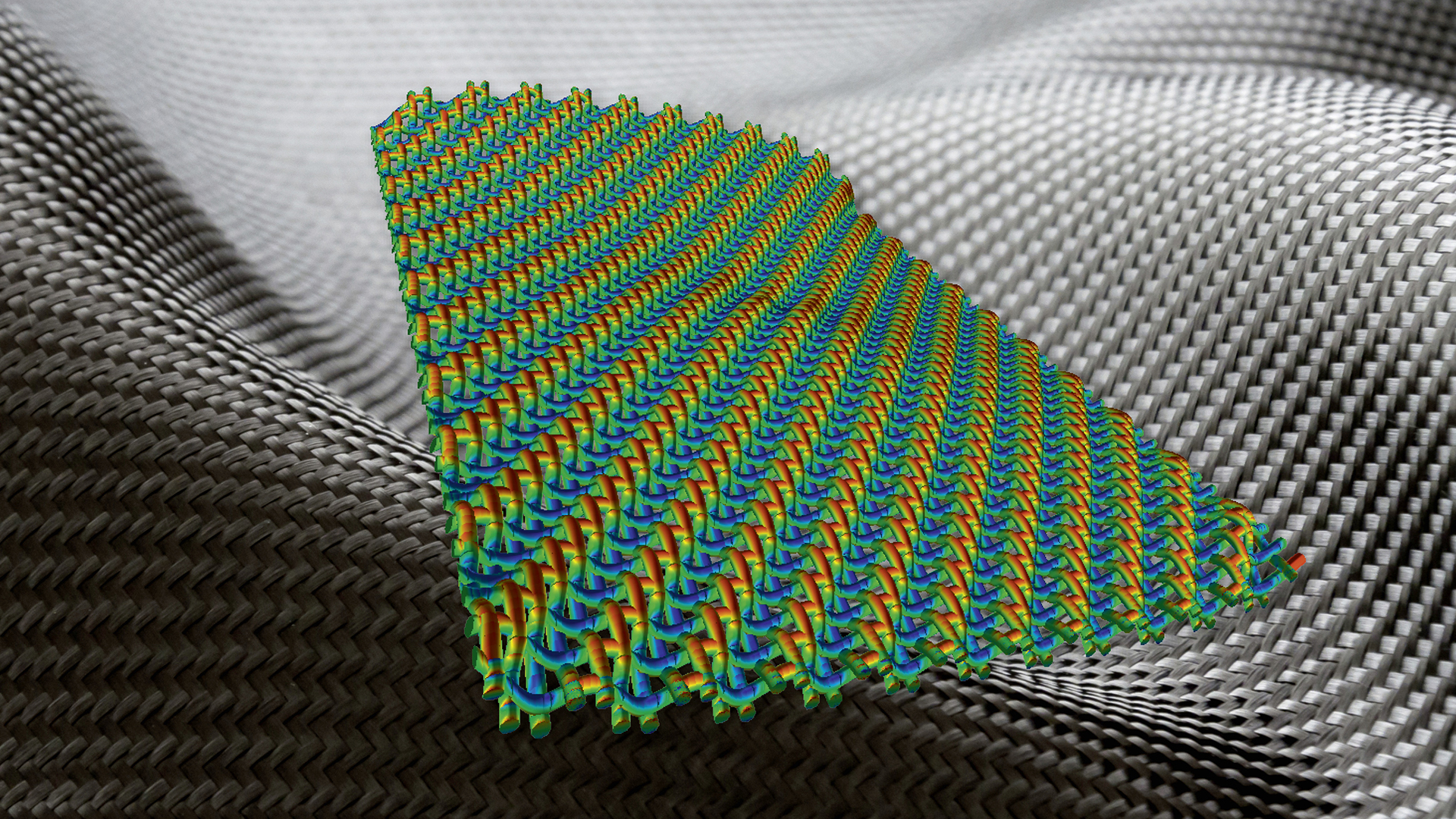

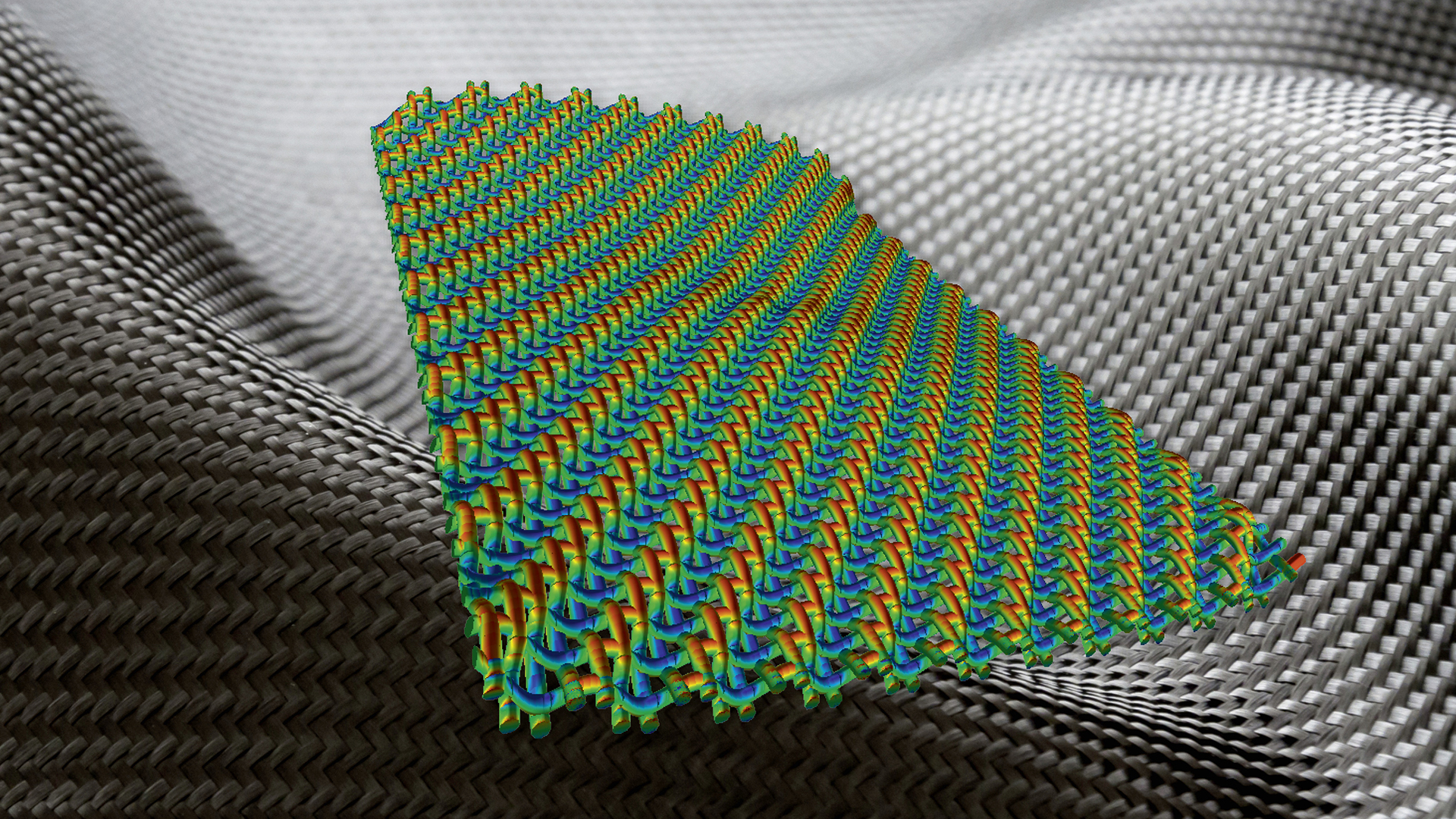

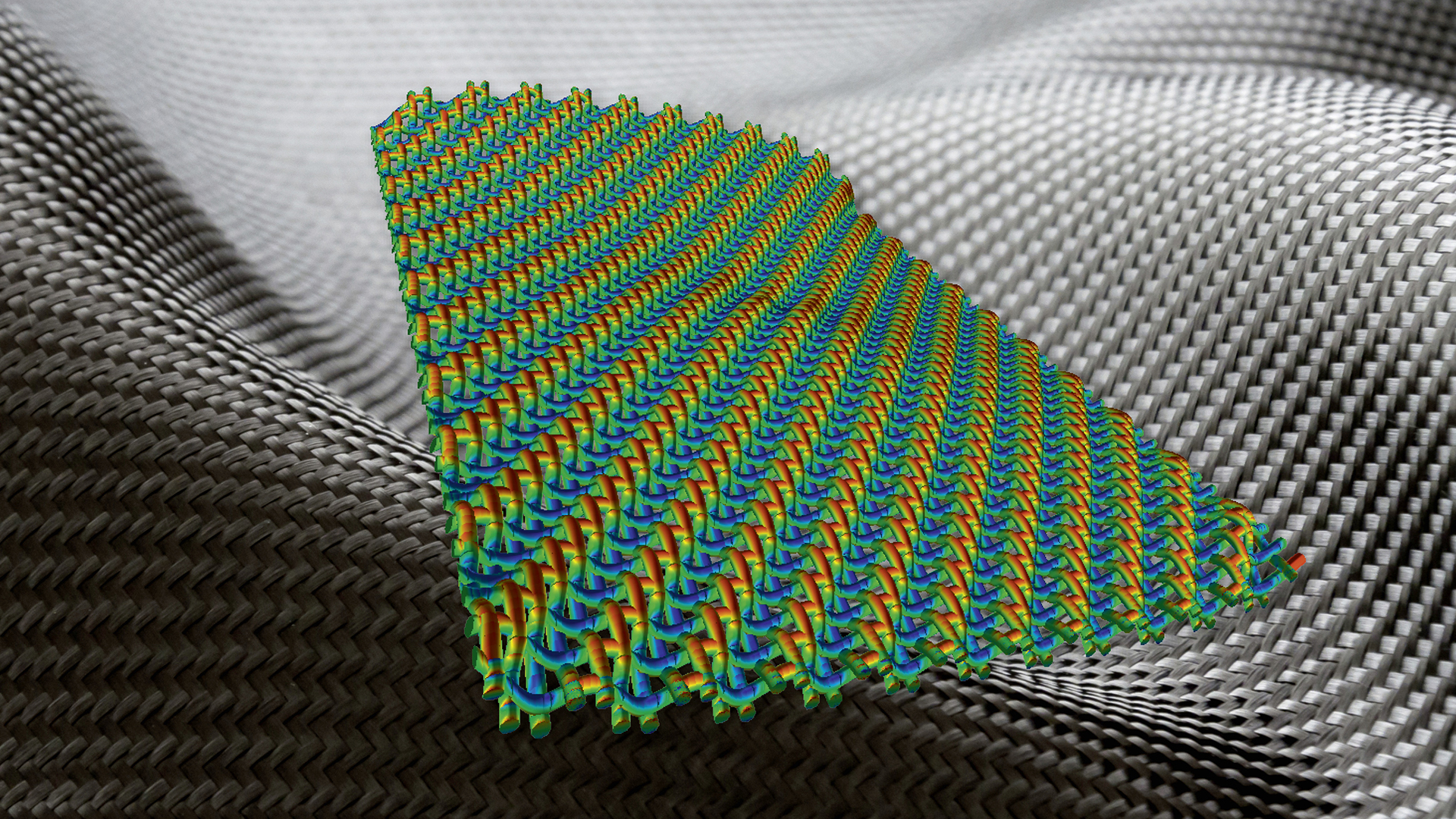

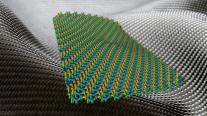

Simulate technical textiles realistically with "TexMath"

Accelerated development and optimized design of technical textiles and nonwovens while reducing the number of experiments? The demand for technologies that can achieve this is particularly high in areas such as the sports, medical and clothing industries. Our TexMath software tool enables efficient prediction of textile behavior under stretch, shear, bending, torsion or compression. The formation of creases under stretching and shrinkage of yarns or critical shear angles can also be simulated and optimized during the entire manufacturing process.

The TexMath simulation software ensures that process chains in production can be adapted to new materials in advance. Complicated patterns and layers can be mapped using the software and a direct connection to the textile machine can be made. The desired woven, knitted and warp-knitted products are precisely calculated with the software and their material properties simulated. In addition to the evaluation of a specific textile design using simulation, the tools also offer the optimization of performance characteristics for different design variants. The aim of the software is to realize the design according to product properties and target criteria.

One area of application for the TexMath software is the optimization of compression textiles for the medical sector or for sports. For optimum effectiveness, the accuracy of fit of the material is particularly important here. For example, TexMath can be used to simulate the knitting process to produce a bandage with predefined compression properties and thus design the optimum knitted fabric. This virtual bandage is then loaded in a further simulation and put on a virtual arm or leg. Thanks to TexMath, the calculated pressure profile makes it possible to evaluate the compression properties of the support in advance and to directly control the knitting machine according to the optimum design.

TexMath can also be used to design spacer textiles, such as those used for the upper material of sports shoes and for the production of high-performance textiles, and to optimize their structure and flow mechanics in advance. The newly developed input interface is particularly user-friendly. The textile class (i.e. knitted, warp-knitted, woven, braided and spacer fabrics) can be easily set. The new graphical interface allows quick and easy configuration.

FeelMath - Mechanical and thermal properties of microstructures

FeelMath is a fast and easy-to-use analysis tool for calculating effective anisotropic mechanical and thermal properties of microstructures given by solid images or analytical descriptions.

Modeling opens a door to so-called digital material design and optimization of materials to determine the following effective material properties:

- Stiffness and strength

- Thermal expansion

- Viscoelastic creep and relaxation

- Elasto-plasticity and damage

- Fatigue at high number of load cycles (high cycle fatigue)

Simple changes to the model parameters are reflected in slightly different geometries, in which the target properties can be simulated.

This cycle can be repeated until the optimum microstructure has been found. In this way, time-consuming and expensive mechanical tests and the production of samples and prototypes can be reduced, while at the same time the relationship between the microstructure and the resulting properties of the material is better understood.

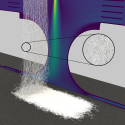

Simulation of filtration and separation

In the "Filtration and Separation" work area, we develop problem-adapted mathematical models, numerical methods and simulation techniques for the computer-aided investigation and optimization of separation processes and methods. Fields of application are filter media and elements, adsorption, reactive flows and fractionation methods as well as the coupling of flow and structural mechanics calculations. We have many years of experience in the design of filter media made of technical textiles.

Many of our research and development results are realized in in-house developments such as the simulation tools FiltEST and PoreChem. In addition, we also offer simulation services as well as simulation consulting in this field of application.

Our product groups

- Research, Development, Education, Consulting

- Technology and Processes

- Woven Fabrics, Laid Webs, Braidings, Knitted Fabrics

- Nonwovens

More about us

Modellierung, Simulation, Optimierung

Keywords

- Spinning Processes

- Digital Twin

- Filtration

- Simulation

- Virtual Material Design

Our Products

TexMath - Simulation of technical textiles

Accelerated development and optimized design of technical textiles and nonwovens while reducing experimentation? The demand for techniques that can realize this is particularly high in areas such as the sports, medical and clothing industries. Our TexMath software tool enables efficient prediction of textile behavior under stretch, shear, bending, torsion or compression. The formation of folds under stretching and shrinkage of yarns or critical shear angles can also be simulated and optimized during the entire manufacturing process.

From high-performance textiles to compression and sportswear: The modular TexMath software program from the Fraunhofer Institute for Industrial Mathematics ITWM enables both the simulation of mechanical material properties and the optimization of textile products.

The TexMath simulation software ensures that process chains in production can be adapted to new materials in advance. Complicated patterns and layers can be mapped using the software and a direct connection to the textile machine can be made. The desired woven, knitted and warp-knitted products are precisely calculated with the software and their material properties simulated. In addition to the evaluation of a specific textile design using simulation, the tools also offer the optimization of performance characteristics for different design variants. The aim of the software is to realize the design according to product properties and target criteria.

One area of application for the TexMath software is the optimization of compression textiles for the medical sector or for sports. For optimum effectiveness, the accuracy of fit of the material is particularly important here. For example, TexMath can be used to simulate the knitting process to produce a bandage with predefined compression properties and thus design the optimum knitted fabric. This virtual bandage is then loaded in a further simulation and put on a virtual arm or leg. Thanks to TexMath, the calculated pressure profile makes it possible to evaluate the compression properties of the support in advance and to directly control the knitting machine according to the optimum design.

TexMath can also be used to design spacer textiles, such as those used for the upper material of sports shoes and for the production of high-performance textiles, and to optimize their structure and flow mechanics in advance. The newly developed input interface is particularly user-friendly. The textile class (i.e. knitted, warp-knitted, woven, braided and spacer fabrics) can be easily set. The new graphical interface allows quick and easy configuration.

TexMath consists of several components: MeshUp, FibreFEM and FIFST. Each of the components contained in TexMath has its specific area of application. In addition, the tools have interfaces with each other as well as connections to the GeoDict® software, which can be used to carry out fluid mechanical simulations on the textiles, for example. An interface with FeelMath enables further detailed three-dimensional mechanical simulations to be carried out on specific yarn or contact points, so that strength and service life can also be investigated.

FIDYST - Fiber Dynamics Simulation Tool

Starting point of the development of the software tool FIDYST was the simulation of nonwoven and spinning processes like spunbond or meltblown. By further developments FIDYST became more and more flexible. FIDYST is developed to simulate the dynamics of line shaped objects, e.g.

- fibers (e.g. cotton or glass wool),

- filaments (in spinning processes),

- yarns and also

- cables.

In the following text these objects are called fibers for simplification.

Modeling of the Fiber Dynamics

The dynamics of the fibers are described by Newtonian equation of motion with internal and external forces. With the internal forces the

- elastic,

- viscous or

- viscoelastic

properties of the fibers are modeled. The external forces describe the

- air drag of the (turbulent) air flow,

- contacts of fibers with (moving) machin parts (e.g. belt,...),

- contacts between fibers,

- gravity or

- electrostatic forces.

In some processes the influence of the turbulence onto the fiber dominates the process. Therefor, a stochastic air drag model was developed which adequately accounts for the characteristic turbulent scales.

Simulation of the Air Flow

The fluid dynamics simulations are done by commercial CFD tools, such as ANSYS-FLUENT or ANSYS-CFX. The fluid data are input data for FIDYST. If a full coupling of the fiber dynamics and the fluid dynamics is necessary, the simulation tools for fluid and fibers are coupled iteratively. The fibers are integrated into the fluid dynamics by source terms for mass, momentum and energy.

Flexibility of FIDYST

FIDYST is developed as a general simulation tool for slender bodies. Thus FIDYST is not restricted to a special application. To apply FIDYST within a new complex industrial process FIDYST can be adapted and extended to the process.

Examples for Applications

spunbond, meltblown, BCF, staple fibers, electro spinning, processing of natural fibers, glass wool production, air weaving,...

https://www.itwm.fraunhofer.de/FIDYST_EN