Fothergill Engineered Fabrics Limited

Fothergill Engineered Fabrics Limited

Summit

Littleborough, Lancashire

OL15 0LR

Great Britain and Northern Ireland

Telephone+44 1706 372414

About us

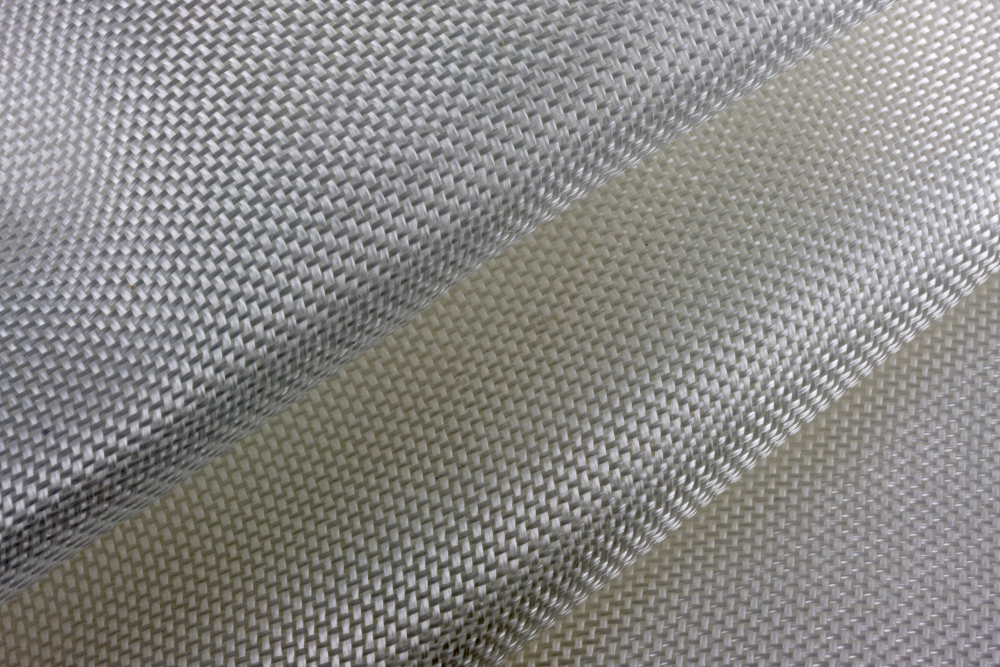

A leading European-based weaver and knitter of glass, silica, aramid, carbon, PTFE & natural fibres. Manufacturer of specialist hybrid fabrics also utilising other fibres, such as stainless steel, in our weaves.

Our product groups

- Woven Fabrics, Laid Webs, Braidings, Knitted Fabrics

Our application areas / Solutions

Keywords

- Weaver

- Aramid

- Carbon

- Woven fabrics

- Glass

Our Products

Defence fabrics

Textile products from Fothergill Engineered Fabrics Ltd were first supplied to the British Army during the Boer War and were more recently battle-proven during the Gulf, Bosnian and Afghanistan conflicts, where they were employed in helmets, body armour and vehicles.

Utilising a wide range of fibres including Carbon, Aramid, Nylon, PTFE, Polyester and S2 Glass, we supply into Europe’s leading non-metallic armour and other defence manufacturers. Fothergill Engineered Fabrics Ltd is Europe’s largest weaver of S2 Glass for ballistics.

Our output extends from lightweight reinforcements to highly sophisticated anti-ballistic materials, for which Fothergill Engineered Fabrics Ltd woven aramid, a high modulus fibre of great tensile strength, provides outstanding protection. Flexible and light to wear, it is proven to be five times stronger than steel, weight for weight.

Such is our expertise in developing new solutions for sensitive problems, that we can design fabrics to provide distinctive properties to match our customer’s exact applications.

From protection for forestry workers and refuse collectors to primary armour, bomb blankets and safety screens, our finishing techniques encompass a vast array of specialist characteristics.

Rigorous testing of new products is carried out on our own five metre Home Office approved firing range, where confidentiality is assured.

High temperature applications

The range of Fothergill Engineered Fabrics Ltd heat resistant materials covers virtually all thermal insulation and thermal protection applications.

Tyglas: Glass fabrics are generally employed as facings for flexible or rigid insulation, having a maximum continuous operating temperature of 550°C. Coated glass fabrics are available for use in the fabrication of flexible ductings, expansion joints and explosion membranes, with differing maximum continuous temperatures, depending on the coating. Special coated fabrics have also been developed for fire blankets to BS EN 1869 (Tyglas FB) and for covering insulation mattresses and valve covers market (Tyglas VC).

Tyglas 1000C: These are texturised glass fabrics which have been specially treated and will withstand a blowtorch flame in excess of 1000°C. Providing increased protection from molten metal spatter, their high strength and abrasion resistance makes them eminently suited to fire barriers and welding blanket applications.

Tygasil: Produced in woven, knitted, and needled mat form, Tygasil silica fabrics have been subjected to a special treatment which increases the silica content to typically a minimum 98%, resulting in a fabric which retains flexibility at the maximum recommended operating temperature of 950°C. These fabrics are excellent for furnace curtains, fire barriers, welding screens and blankets.

Knitted Tygasil: Combining the features of woven silica with improved flexibility and high insulation properties, knitted Tygasil contains no respirable fibres. Assuring high standards of worker safety and comfort, it provides an efficient and cost effective replacement for refractory ceramic fibres (RCF’s) in industrial insulation and heat treatment operations.

High Temperature Filtration Products: Filter fabric technology (for hot gas filtration) has been a speciality of Fothergill Engineered Fabrics for almost forty years, since the introduction of manufacturing from monofilament polyester and other yarns. Our technical staff work closely with customers in the development of specially treated glass fabrics for the filtration of molten aluminium. The impetus towards advancing fabric technology often springs from developing materials to satisfy our customers’ special requirements. In this manner, aramid, quartz and other yarns are included in our product range.

Aerospace, reinforcements & composites

We supply a wide range of woven glass, carbon, aramid, nylon, PTFE and polyester into the aerospace, reinforcement and composite industries.

Our product range includes industry standard and custom designed specialist woven fabrics for aerospace and high performance composite applications. With a wide range of different fabric styles woven from carbon, aramid and glass fibres, we offer fabrics which are value engineered and provide tailored structural properties.

Bespoke hybrid fabric weave pattern solutions, such as carbon/glass and carbon/aramid, can also be developed in conjunction with our technical team, to satisfy customer specific requirements.

Our range of woven glass fabrics can also be batch heat cleaned with either industry standard or specialist internal proprietary finish treatments. These aid handling, improve adhesion of fibres and provide specific resin compatibility to the chosen matrix.

Fabrics with Alternative Weaves, Finishes and Coatings

Weaver of specialist alternative fibres to satisfy bespoke customer requirements, such as stainless steel and hybrid fibre blends. We also offer specialist finishing / coating applications to further enhance fabric properties.

A wide variety of chemical treatments are offered to improve fabric properties and/or to make fabrics more suitable for customers’ further processing. Fabrics are also offered laminated to aluminium foil, or coated with elastomeric, or other proprietary coatings.

Varying weave constructions produce different physical characteristics, which may be beneficial for a particular usage.

The four principal weaves are:

Plain - for abrasion resistance and stability. Ideally suited to flat surfaces.

Twill - for covering curved surfaces.

Satin - more suitable for draping providing increased flexibility.

Matt - similar to plain, but with greater strength.

Fabrics for PTFE & elastomer coating

Over 35 years’ experience producing fabrics especially for the PTFE and elastomer coating industries.

Closed weave

Open mesh fabric styles

Broad range of woven glass and aramid fabric styles

Our Contact Persons

Simon Onslow

Sales

Sales Representative/Agent