ERHARDT + LEIMER GMBH

Address

ERHARDT + LEIMER GMBH

Albert-Leimer-Platz 1

86391 Stadtbergen

Germany

Telephone+49 821 24350

Fax+49 821 2435666

Discover more from us

Follow us on

About us

TOP TECHNOLOGY - AT HOME ALL OVER THE WORLD

Erhardt+Leimer is an internationally oriented, privately owned group of companies with its head office in Augsburg, Germany. It was founded in 1919 and, in 2019, employed more than 1.600 people around the world. In 2023 they generated a turnover of 210 million Euros.

Our core business is automation technology on moving webs, which we can offer with different levels of integration in various industries. Our subsidiaries and additional industrial representatives mean that we are represented in the most important industrial countries.

Our product groups

- Technology and Processes

Our application areas / Solutions

Keywords

- Bahnkraftregelung, Bahnschneidsystem, Bahnlaufregelung

- Bahnführung, Ausbreitsystem

- WebTension Controll, Web Cutting, Web Guiding

- Web Spreading

- WebTension Measuring

Our Products

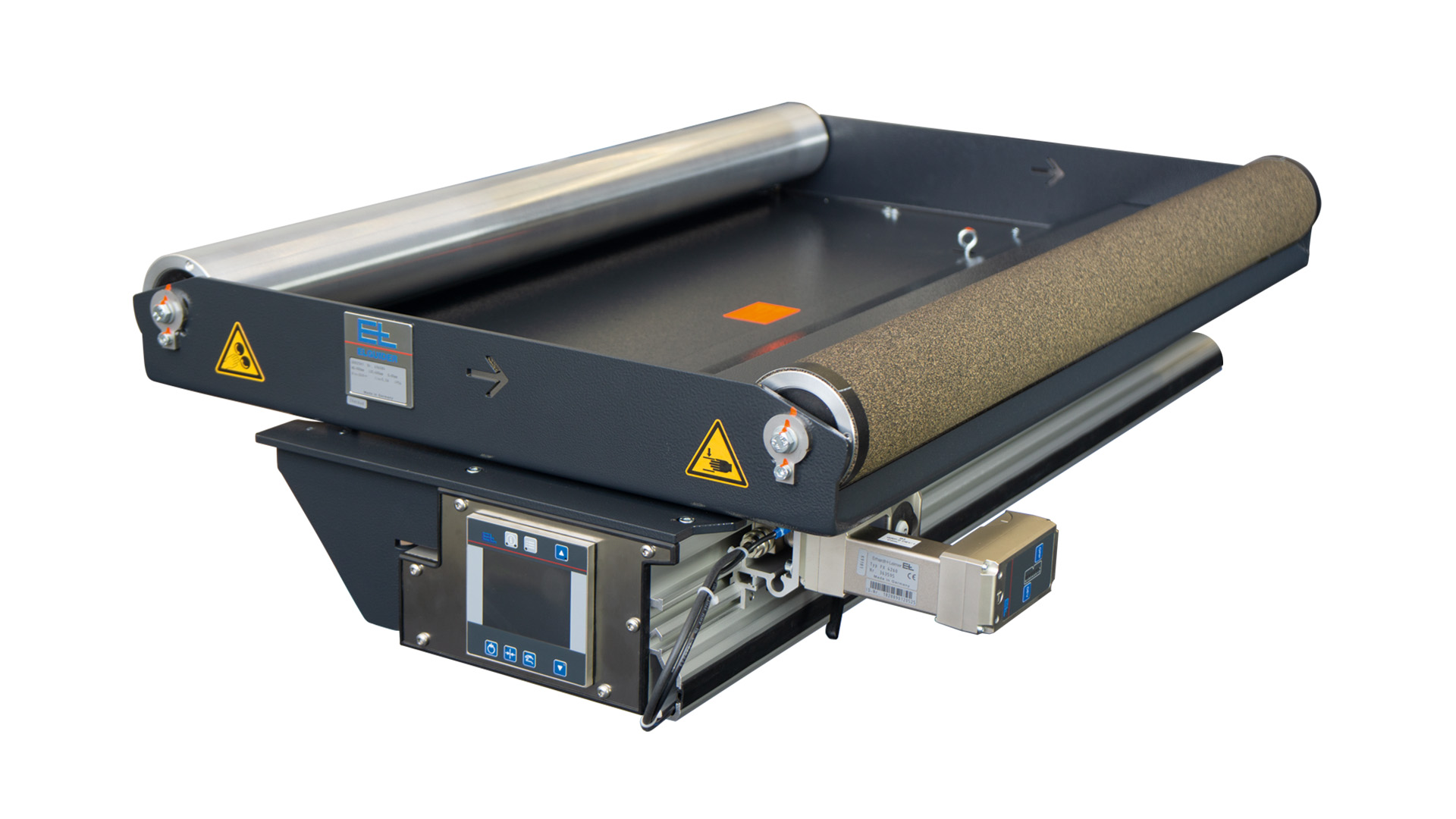

SYSTEMS FOR WEB GUIDING AND SPREADING - ELSMART

Guiding and spreading are the key tasks for positionally accurate and crease-free alignment of textile webs. These tasks are both performed by the ELSMART system at the same time. The web guiding rollers ensure optimum web guiding across the entire textile processing spectrum.

Product description:

- Precise web guide of woven and knitted fabrics in dry and moist operation or rubberized webs out of the loop

- Integrated edge detection with broadband sensor or infrared edge sensor

- Gentle and safe control of the textile web using the electrical actuating drive of the segmented roller guider up to a machine speed of 50 m/min

- Continuous guiding slats for web guiding, split guiding slats for web guiding with overlaid spreading

- Optionally with web tension-controlled additional drive for constant web tension in the downstream process

METAL DETECTION SYSTEMS - ELMETA

METAL DETECTION SYSTEMS ARE ESSENTIAL FOR TEXTILE PRODUCTION PROCESSES

During the processing of textile webs, there is a risk of small metallic particles entering the fabric as a result of the different processing steps. If these are not fully detected, there is a risk of expensive resulting damage to the calender or shear blade.

Product description:

- Reliable detection of spherical metals at a distance of < 1 mm from the scanning surface

- One signal LED per segment (300 mm)

- Pulsed signal can be set from 0.5 to 5 s

- Compact design with integrated electronics

- Straightforward mounting at two points

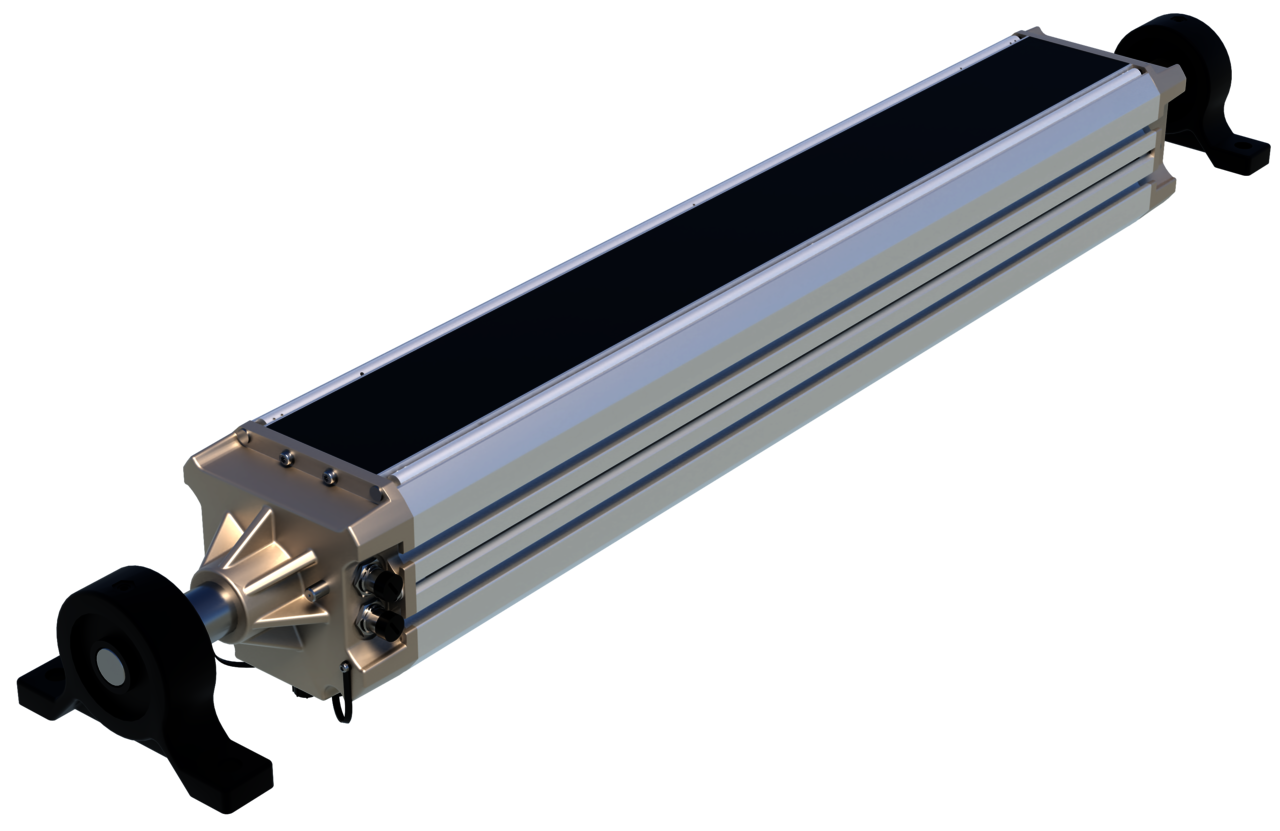

Web Tension Measuring and Control systems ELTENS

Reliable control of the web tension using a tension sensor helps to reduce web tears and therefore keeps production costs down. ELTENS web tension measurement and control systems are used all around the world to achieve reliable and high-quality production.

Product Description:

- Position-independent installation due to various mounting options such as flange bearings, pedestal bearings, inner or outer fastening

- Maximum operational reliability due to overload protection up to 20 times the nominal measuring force

- Different shaft diameters from 12 to 65 mm and nominal measuring forces from 0.05 to 10 kN ensure a high degree of flexibility

- In case of horizontal measuring direction, no influence on the measuring result due to the weight of the roller

- Good temperature behavior and a high degree of linearity of the measuring elements due to strain gauge application on a flat surface

Web Guiding Systems ELGUIDER

The elimination of possible error inducing variables, the permanent and exact alignment of the web and the guarantee of precise reel formation is the task of the E+L web guiding systems.

Keeping in mind the type of material handled, the given application and the specific task Erhardt+Leimer will offer the right solution from a large diversity of different systems: for better quality and higher productivity for the benefit of our customers.

Web Cutting Systems ELCUT

CUTTING TECHNOLOGY SYSTEMS GUARANTEE THE HIGHEST CUTTING ACCURACY

Less spoilage, lower production costs, fewer complaints – the investment in efficient cut technologies will pay for itself within a short space of time. With the ELCUT system, you can carry out all due tasks to the highest quality – from edge trimming to the separation of webs into several panels.

Product description:

- Shear cut principle with driven top and bottom blades

- Internal/external motor installation

- Blade shaft for max. 240 mm cut-off

- Suitable for edge cutting of paper, foil, textile, carpet, non-woven fabric, and felt webs

- Fixed cutting speed or optionally adjustable with frequency converter