DELCOTEX Delius Techtex GmbH & Co. KG

DeliComp®

Explore product

DeliComp®

Explore product

DeliComp®

Explore productAddress

DELCOTEX Delius Techtex GmbH & Co. KG

Vilsendorfer Str. 50

33739 Bielefeld

Germany

Telephone+49 5206 91070

Fax+49 5206 910760

Discover more from us

Follow us on

About us

Technical Textiles – German Engineering since 1722

DELCOTEX develops, optimises and produces technical textiles for different branches and according to international standards. We are producing innovative textiles for the European market with 150 employees at our production site in Bielefeld. DELCOTEX has grown to a market leader in Europe because of the following reasons: large machinery and laying machines with best available technology and consequent customizing of development, technology and organisation as well as our principles like adherence to delivery dates and economic efficiency.

Our comprehensive know-how and our great experience coupled with your requirements lead to superior technical textiles; these simplify daily life and makes it more secure. They also protect our environment.

DELCOTEX is using filament yarns made of polyamide, polyester, aramid, and glass. Our fabrics weigh between 30 g/m² up to 1500 g/m²; the width extends to 520 cm. Our article range includes:

- DeliComp® – Thermoplastic prepregs

- Backing fabrics

- Process fabrics

- Scrim fabrics woven and laid

Our product groups

- Woven Fabrics, Laid Webs, Braidings, Knitted Fabrics

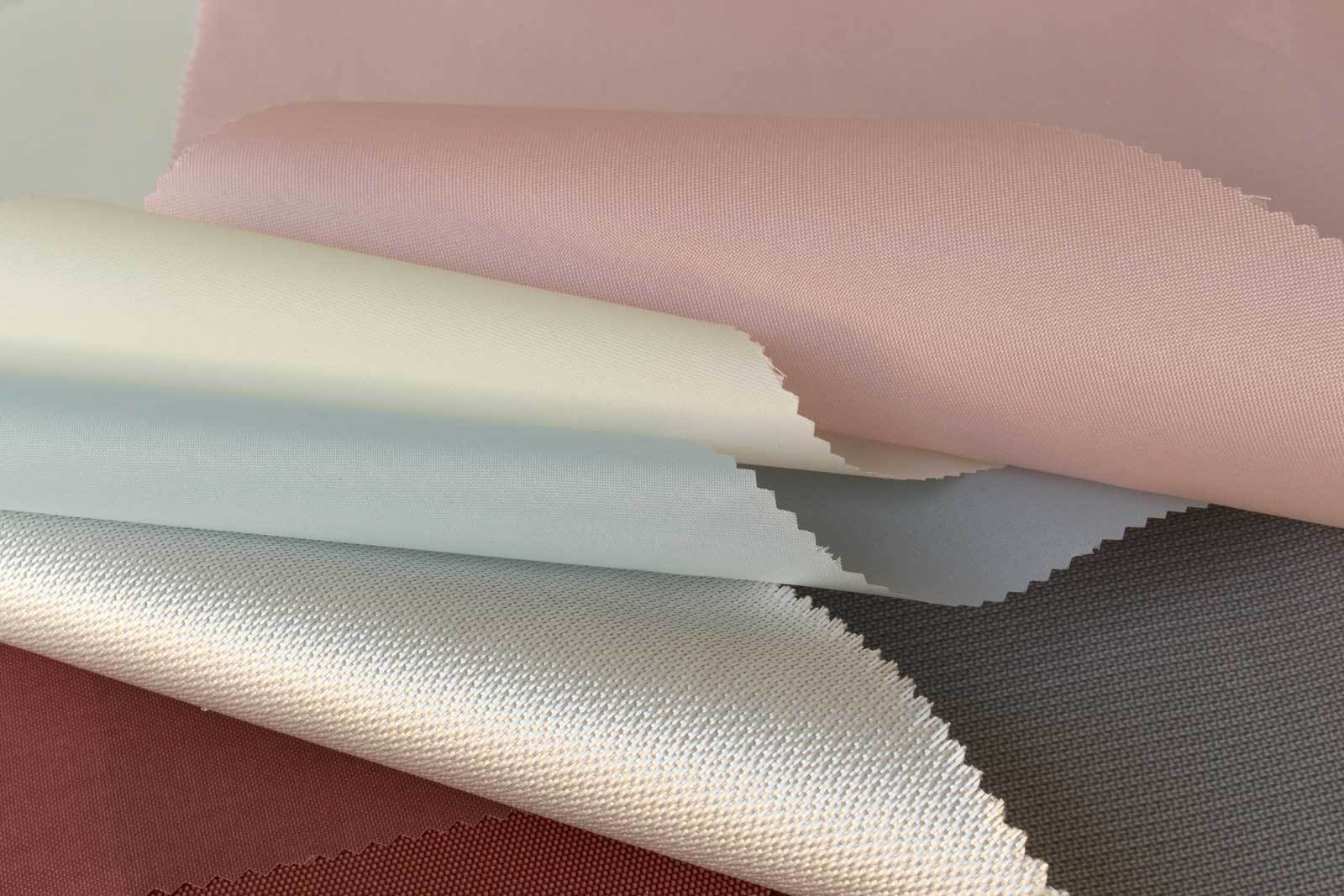

- Coated Textiles

- Composites

More about us

Special Interests

Keywords

- Technische Gewebe / technical fabrics

- Cordura

- Composite

- Gittergewebe und Gelege / laid and woven scrim

- Textil Labor / textile laboratory

Our Products

COLLECTION

We keep in our stock a wide range of technical textiles for all kind of purposes, which you can call off any time:

- CORDURA® Fabrics

- flame retardant fabrics

- coated fabrics.

Finished fabrics for:

- Sport, leisure time, mobility

- Work and Protection wear

- Military

- Textile light construction

- Printing

Finished fabrics with e.g. PU, AC, PVC, ceramic... We are keeping a wide range of technical fabrics for different purposes for you.

PROCESS FABRICS

Our silicon fabrics are extremely long living and can be used in your production process up to more than 30 production cycles. Due to this frequent number of uses our silicon backing cloths are a lot cheaper in the long term than non-silicon backing cloths.

Depending on the use, your production machines or the finished product requirements we supply:

- many different base fabrics for the surface formation of you products

- silicon coated either one-sided or double-sided (about 25 - 100 g/m² per side)

- minimally silicon impregnated fabrics (about 5 -10 g/m²)

- fabrics in different colours for easy differentiation or type allocation of differing backing cloths in your production

- precise roll lengths without seams

- minimal fault frequency

- optimum wind

DeliComp®

Ready for immediate processing | Cost-efficient | Environmentally friendly DeliComp® is a new type of thermoplastic prepreg. It consists of woven glass fi bers and a thermoplastic matrix. The DELCOTEX infusion process guarantees an even penetration of the fibres by the matrix. DeliComp® was developed as a material for structural reinforcements. It can be used as an inlay for injection molding or for lamination to other materials.

The use of DeliComp® offers the following advantages in finished products:

- reduction of process steps

- low energy consumption while thermoforming

- cost reduction

- weight reduction

- constant ratio of glassfiber and matrix

- flexible and easy forming

- increased tensile strength

- enhanced impact strength

- improved fracture behaviour

- constant dimension stabilility and thickness

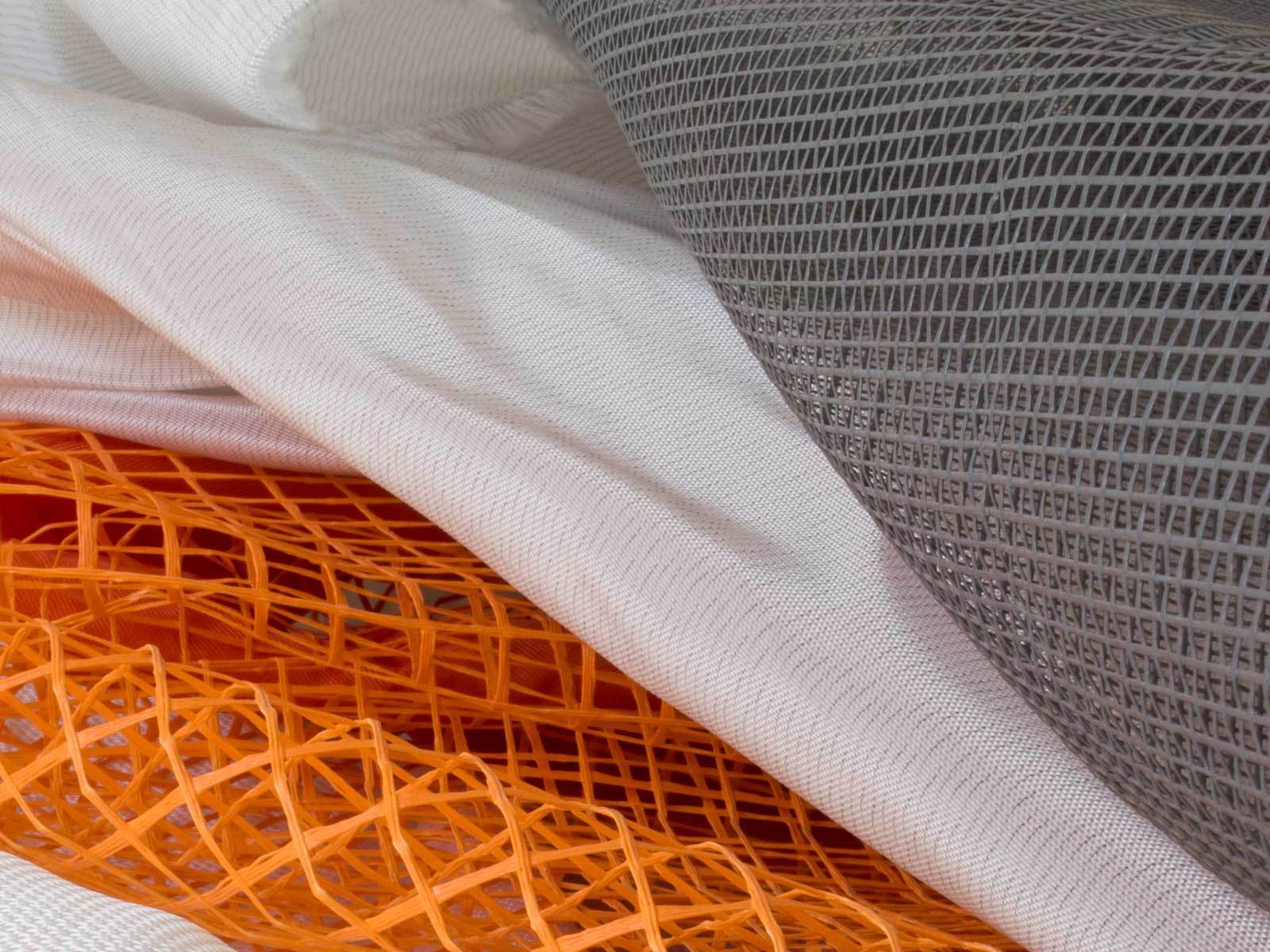

SCRIM FABRICS WOVEN AND LAID

Woven scrim fabrics and laid scrim fabrics from DELCOTEX are multi-functional coating substrates. Scrim fabrics are made of filament yarns and are used as hidden reinforcements for many products. Weaving and stabilizing of scrim fabrics are done in one production process.

Woven scrim

For many technical requirements DELCOTEX is manufacturing multi-functional scrim fabrics according to the newest technical standards. Fields of application:

- Roofing insulation membranes

- Swimming pool membranes

- Reinforcement of facades

- Wind and sun protection

- Digitial printig for large-area commercials

- Laminating of foils

- Reinforcement of fleece and needle felt

- Reinforcement for molding components

- ... and custom-made production

Laid scrim

The good alternative to woven scrim In a laid scrim, the yarns are stacked, not interlocked. PES and Glass yarns are commonly used. The advantages of laid scrims are faster production, a perfect flat dimension stability and lower thickness. Fields of application:

- Roofing insulation membranes

- Packaging materials

- Isolation materials

- Sails

- Carpets

- Greenhouse films

- Covering for fields

- ... and custom-made production

Profile of woven scrim fabric

- Fabric width up to 345 cm

- Coating weight from approx. 10 – 100g/sqm

- Roll length from 100 – 10.000 mts.

- Optimal dimensional stability

- Perfect flat dimension stability

- Low rest shrinkage

Profile of laid scrim fabric

- Fabric width up to 240 cm

- Coating weight from approx. 10g – 150gr/sqm

- Roll length up to 10.000 mts.

- Good flat dimension stability

- Low rest shrinkage

- Lower thickness in comparison to other fabrics

BACKING FABRIC

There are different types of backing fabrics for various purposes:

- washed out, heat-set and calandered

- with coupling systems for rubberization

- for industrial timing belts

- for conveyor belts

Backing fabrics – washed out, heat-set and calandered

The advantages of DELCOTEX backing fabrics:

- high-quality surfaces

- perfect adhesion

- problemfree coating processes

Almost limitless properties profile:

- fabric widths up to 520 cm

- fabric density from 30 - 1500 g/m²

- yarn counts from 10 dtex - 5500 dtex, multi-/monofilament

- cutting cold/hot/ultrasonic

- piece lengths several meters wihout a seam

- 100% optical merchandise evaluation

- error log in 3 languages if desired

- perfectly stress-optimized roll winding

- packaging on cardboard tubes, steel core, etc.