D³-Solutions GmbH

Discover more from us

About us

D³-Solutions - Your Partner for Innovative Solutions in Textile Machinery!

Are you seeking tailored solutions to enhance efficiency and product quality in your textile operation? D³-Solutions is your dependable partner for engineering, consulting, and 3D printing technologies! Our experienced team develops custom textile machinery precisely tailored to your requirements. From optimizing your production processes to integrating advanced automation technologies - we take your production to the next level.

With our comprehensive consulting, we assist you in analyzing your needs and developing solutions that effectively address your challenges in textile machinery. We help you eliminate bottlenecks, reduce operating costs, and optimize your staff's skills.

Thanks to our innovative 3D printing technologies, we offer you the ability to quickly create prototypes, produce custom components, and realize innovative designs. This ensures you not only receive high-quality textile machinery but also tailored components that meet your requirements.

Rely on D³-Solutions for outstanding performance in textile machinery. Contact us today and discover how we can help you achieve your production goals!

But that's not all!

At D³-Solutions, we also place great importance on sustainability and environmental compatibility. That's why we continuously work on developing solutions that not only increase efficiency but also minimize resource consumption and reduce waste.

Our commitment to environmental protection is also reflected in our 3D printing processes. By using innovative materials and advanced manufacturing techniques, we can produce components with minimal material usage and lower energy consumption, without compromising quality.

With D³-Solutions, you not only receive top-notch performance in textile machinery but also the assurance that you're operating your business sustainably. Take the step towards an environmentally conscious future - choose D³-Solutions as your partner for textile machinery and innovation.

Our product groups

- Technology and Processes

Our application areas / Solutions

Downloads

Keywords

- centrewinder

- batch winder

- rewinder

- Zentrumswickler

- Dockenwickler

Our Products

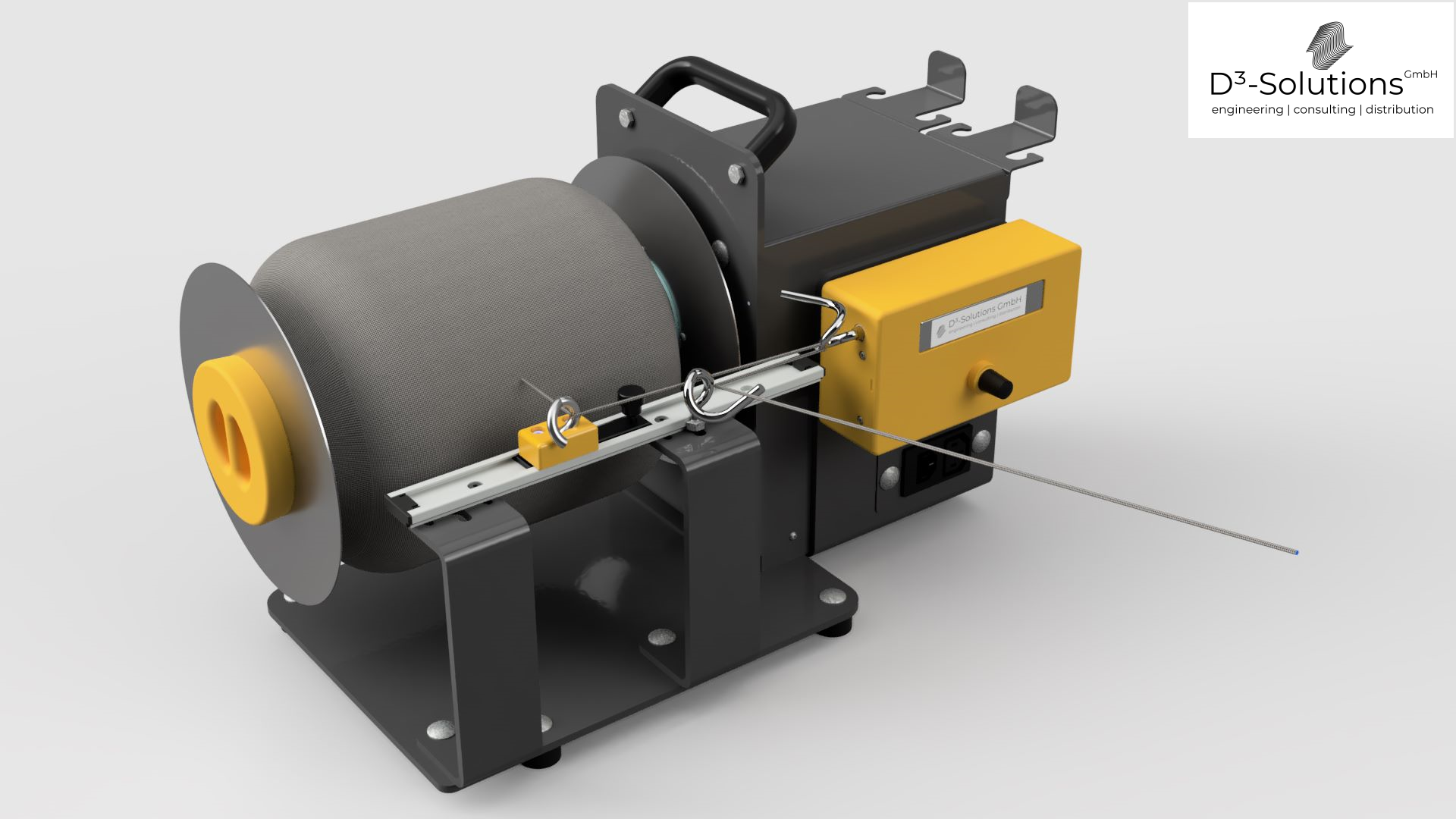

Thread and edge winder

Thread and edge winders from D3-Solutions GmbH offer many advantages. In addition to low power consumption, automatic activation and deactivation, as well as extremely high mobility and stability, we provide highly flexible deployment options.

Our winders are characterized as follows:

- Low power consumption: With low power consumption, these devices can help reduce energy costs and environmental impact. This is especially important in times when energy efficiency and sustainability are increasingly crucial.

- Automatic activation and deactivation: Automatic activation and deactivation ensure that the devices are only active when needed, saving energy, preventing unnecessary wear, and extending the devices' lifespan.

- Extremely mobile and flexible deployment: High mobility and flexibility allow for easy deployment of the devices in various locations and quick adaptation to changing requirements. This increases the efficiency and versatility of the devices and can optimize production processes.

These clear advantages make such devices or tools attractive to companies and organizations looking to reduce operating costs, optimize production processes, and implement more environmentally friendly solutions.

The mentioned benefits are complemented by increased process security, as the devices do not need to be turned on or off separately. Automatic activation and deactivation minimize the risk of human errors, leading to a reduction in production faults. Since the devices are active only when needed, the consistency and reliability of production processes are enhanced. This contributes to improving the quality of manufactured products and reducing the defect rate, thereby increasing efficiency and lowering costs.

adjustable weaving comb

The adjustable weaving comb from D3-Solutions GmbH is used for a precise and regulated feeding of yarns and threads in warp beam production as well as in warp knitting and weaving processes.

The density of the yarn and thread strands in the feed can be regulated quickly and easily.

Sample and series production can be adapted and optimized quickly and efficiently. Time-consuming changes of rigid reeds are a thing of the past. This is a gentle and time-saving aspect, especially in pre-series production and applications with cost-intensive materials.

The substructure made of 3D-printed carbon filament with its exceptional properties has a scissor-like structure. The precisely held combs can be easily adjusted in width and exchanged.

unrolling tray

The unrolling tray from D3-Solutions GmbH is particularly suitable for use in recycling applications within production.

The compact design and mobility makes them to be used flexible.

Main function is to separate different material fractions on a roll, which can then be further processed unmixed.

Simple insertion of material rolls and the ergonomic design enable a safe and effortless operation of the tray.

In recycling applications, it is crucial to separate different material fractions efficiently. The D³ unrolling tray offers a simple solution for this. Thanks to the precise control unit of the unwinding process, bales of material can be unrolled effortlessly and the different materials separated. This enables an efficient processing of recycled materials and helps to optimize the entire recycling process.

lift truck

In the manufacturing industry for technical textiles, efficient and cost-effective lifting devices play a crucial role. Their versatility and adaptability contribute to enhancing productivity and streamlining workflows. From handling raw materials to transporting finished products within production facilities and storage areas, customized lifting systems provide a reliable solution for diverse requirements.

The product range includes a wide variety of manual and semi-electric lift trucks, manufactured with dank der stainless steel or specially coated materials. The enclosed construction and smooth surface design prevent the accumulation of dirt, dust, and chemicals. This facilitates easy cleaning and minimizes the risk of cross-contamination.

The flexible handling and adaptability to various handling tasks contribute to increasing productivity while reducing costs. You can rely on us to optimize your production of technical textiles and meet the highest quality standards.

surface winder

Precise surface winders play a decisive role in the field of technical textiles.

The surface winder from D3-Solutions GmbH use a precise measuring device to control the fabric tension in the infeed.

In this way, a constant web tension and the gentlest possible fabric tension can be achieved. This minimizes the curling, shifting and shrinking of the fabric.

The tension of the fabric in the winder is controlled independently of the fabric infeed tension. This means that the fabric can be wound with virtually no elongation or loss of width.

The stable winding facilitates further processing in the next process steps and ensures product quality during storage and transportation.

Material losses are thus minimized and production efficiency is increased accordingly.

The HMI terminal offers many advantages:

- user-friendliness

- intuitive

- graphical user interface (GUI)

- process data

- process data management of different articles

- simple programming

- visualization

- process data in real time

- monitoring

- verification

- early detection of problems

- security functions/ access restrictions

- increasing process security

- safety in the workplace

- diagnostic functions

- error identification

- easier maintenance

Operation, maintenance and inspection of the production system during operation is made possible by safe access to the machine via the catwalk with inlaid aluminum checker plates.