BEMATIC

About us

At the beginning the activity of the Company was the repairing and manufacturing of textile machinery for the Prato district, but in the last forty years the Company has transferred its attention towards the international markets, attending the most important exhibitions in this sector and beginning its quick accession to a position of worldwide leader in the production of machinery for Non Woven.

In 2010 Bettarini & Serafini - bematic ® has moved to its own premises, in a building with a surface of 3.000 square meters. The new seat, located in Prato, enjoys a strategic position at about 5 minutes from the highway exit Prato East and about 15 Km from Florence airport.

Today Bettarini&Serafini - bematic ® is present on the foreign markets as a modern Company, which is open to its customers’ requirements . Thanks to the high achieved performances, the Company is able to propose versatile plants, which are, at the same time, simple and effective.

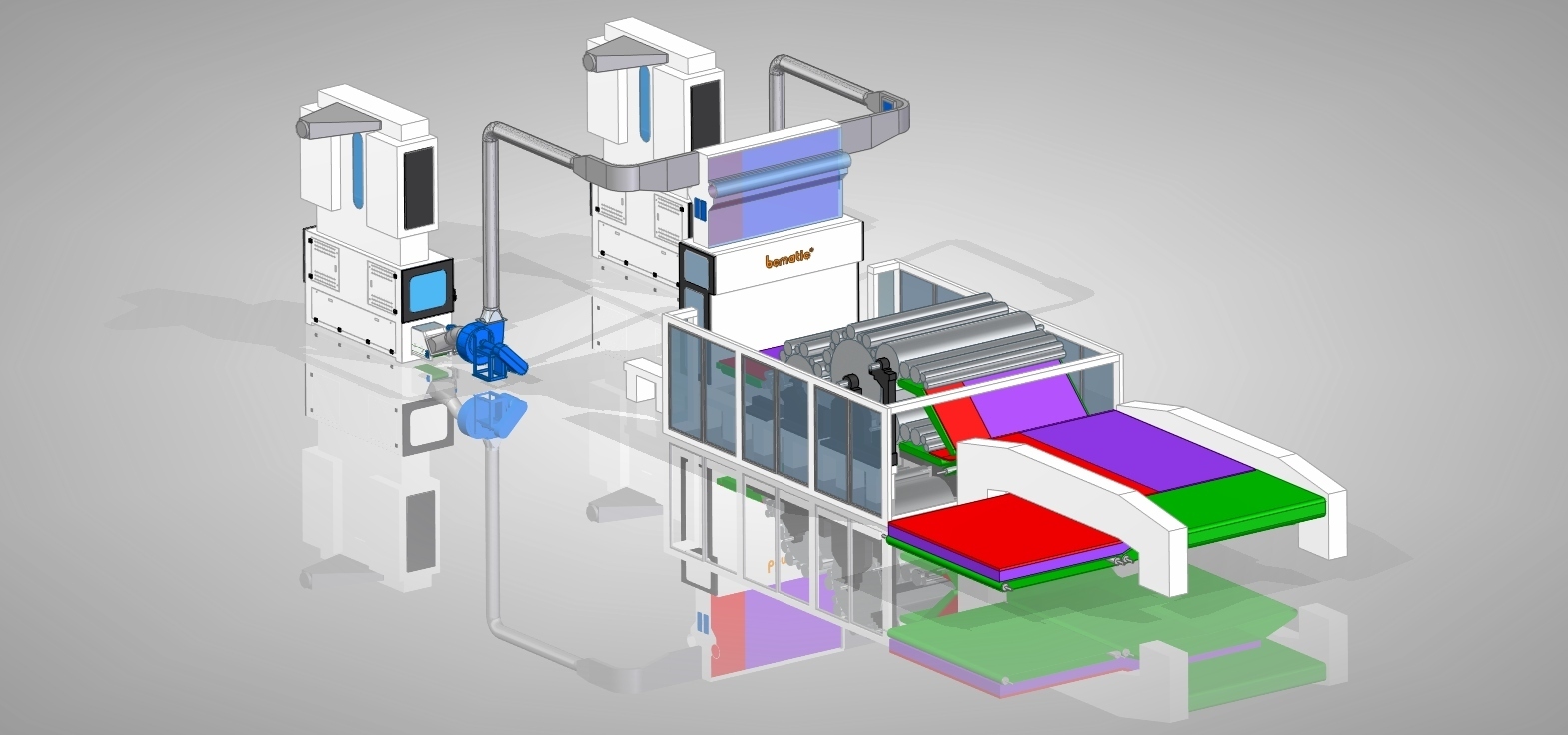

The production range is divided in two categories: one is the direct felt line and the other one is the more traditional line.

- The direct felt line is a new air technology, which has been planned and developed to manufacture Non Woven by processing any type of fibre , textile wastes and also non textile components, such as cellulose and wooden fibres.

- The traditional line equipped with card, for all the traditional Non Woven sectors: from the needled, to the thermo-bond up to the calendared sector.

Our services are:

- Complete nonwovens lines with carding machine

- Complete nonwovens lines with aerodynamic equipment

- Complete laboratory nonwovens line

- Single equipment to install in existing nonwovens lines

- Single equipment to install in new nonwoven lines collaborating with other nonwoven suppliers

Our products in particular are: Feeding preparation, Hopper feeder, Weight control, cards, Former, cut trimming and accessories as Condenser, Duct switch T-valve Metal detector, magnetic detector and filter mod CF/CFR

Final products have different applications as Geotextile, Abrasive, medical, bedding and mattresses products, building/construction/insulation, automotive and appliance products, furniture and foam replacement etc.

Our product groups

- Technology and Processes

Our application areas / Solutions

Keywords

- direct felt line

- Carding machine

- plant for nonwovens

- non wovens line

- laboratory nonwovens line

Our Products

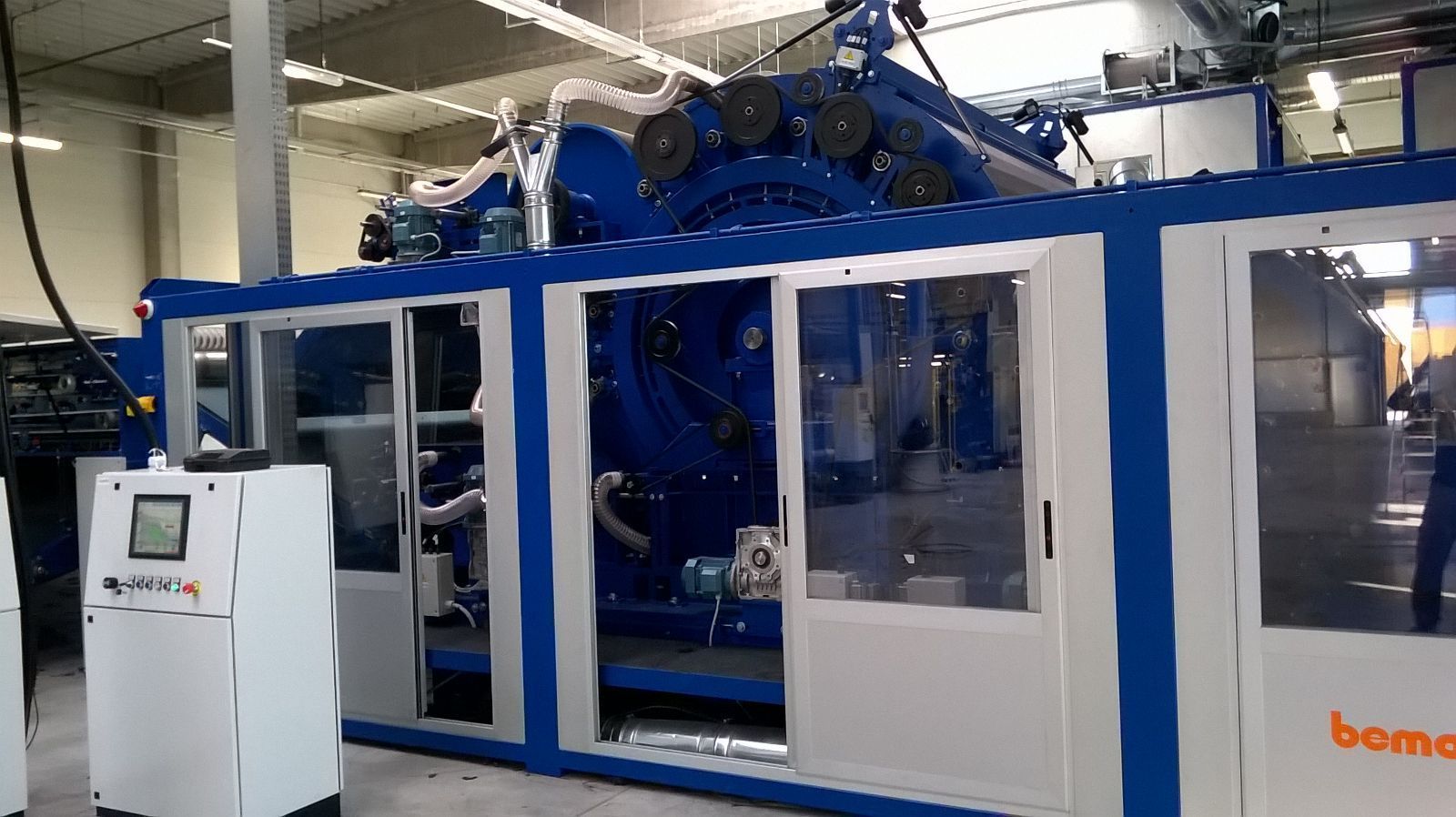

Carding machine

We can offer different type of carding machine according to request of the customers

Working widths from 2,0 mt. to 3,5 mt.

production per hour up to 1500 Kg/h.

The carding machines can be equipped with several options:

- volumetric hopper feeder BCV, chute feed bemafeed, bemadouble

- Electronic control of the weight mod. Bemamultiscale or Bemascale.

- take web off roll for parallel web, random group for random web, combine system parallel web and random web.

- Delivery system with single doffer or double doffer.

- Automatic edge of the web suction system and collecting filter.

Laboratory carding machine

We can offer laboratory carding machine according to request of the customers

Working widths from 0,3 to 1,5 mt.

System to feed by hand

System to feed automatically from bale opener

The laboratory carding machines can be equipped with several options:

- take web off roll for parallel web or random group for random web.

Former T-MAX 350

Air vertical former for the production of insulating products, thermo-and sound proofing, deadening products for the building, furniture, automobile sectors, etc. Our former can feed an oven, a needling machine or a quilting machine. The machine is composed of:

- Upper part with double chamber in depression for the fiber distribution.

- Intermediate part with double feeding and fiber orientation with a specific spiked roller.

- Adjustable lower part for the forming and compacting of the fiber under pressure.

- Delivery part with conveyors with adjustable condensing belt.

Thickness of the product from 50 mm. to 350 mm.

Weight of the product from 500 gr/m2 to 10000 gr/m2

Max. hourly production 3500 Kg/h.

Working widths from 1.5 mt. to 5,0 mt.

Bemadouble

Volumetric tower, specific for the forming of a carding web composed of two-colored fibers or of different composition, to be feed to the carding machine

The machine is composed of:

- Upper part with two in depression adjustable chambers for the fiber distribution.

- Intermediate part for the feeding and pre-opening with spiked roller.

- Lower part for the fiber forming and compacting.

Working widths from 2,5 mt. to 3,5 mt.

Max. hourly production 1000 Kg/h.

Edge trim opener

equipment to re-open waste coming from nonwoven products to use it again :

- Working widths from 0,5 mt. to 2,0 mt.

- one type with pin roll.

- one type with carding rolls.