The exhibitors & products at Techtextil 2026 will be available here from mid-January 2026.

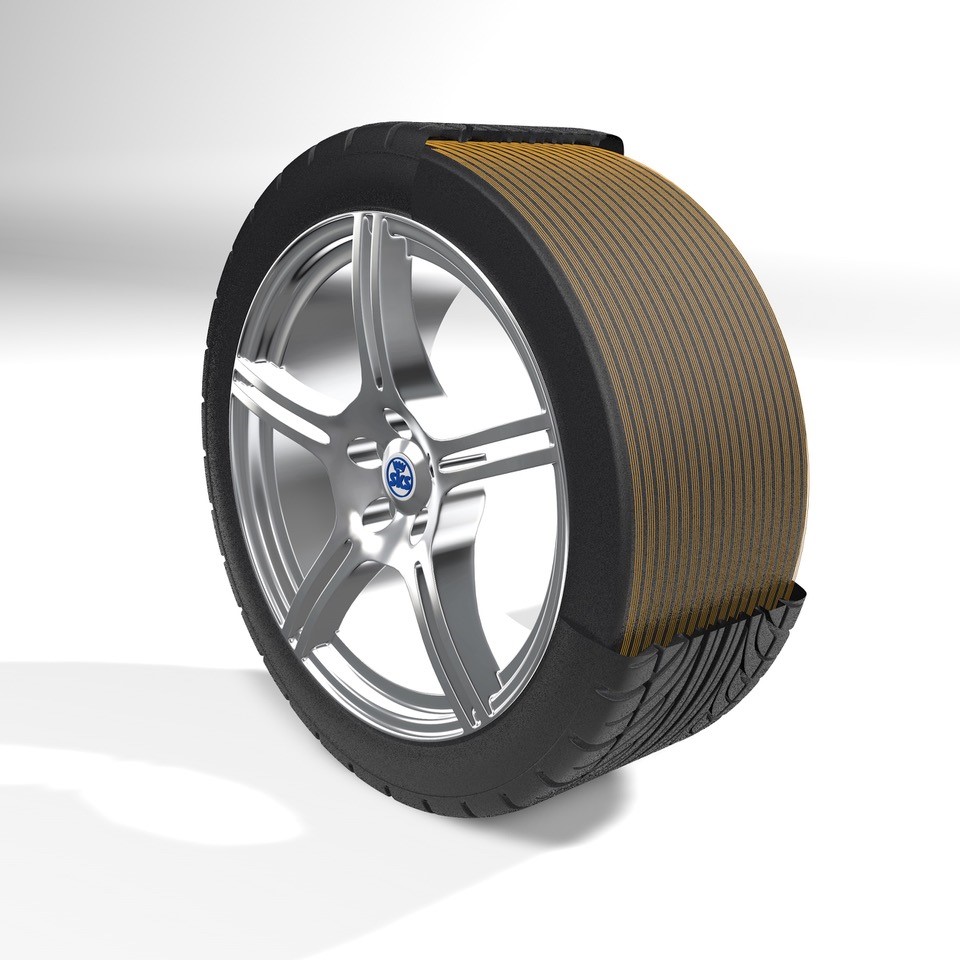

Single End Yarn for Automotive and Industrial Hoses

Single End Yarn for Automotive and Industrial Hoses

Description

The challenge for today’s hose manufacturers is to meet the ever-increasing demands of industry and OEMs for higher working pressures, more flexible handling, excellent dynamic performance, greater durability, and safer, “greener” products. SKS meets these diverse demands with a wide range of high-tech yarns for hose reinforcement.

Aramid:

- High breaking tenacity with low elongation and creep to ensure high working pressure

- High flexibility and dimensional stability,and good chemical and heat resistance

- Linear density range from 420–3360 dtex (including plied constructions)

- Available as twisted greige yarn or RFL-dipped yarn for excellent adhesion

Polyvinylalcohol (PVA):

- High breaking tenacity with low elongation and low shrinkage for high dimensional stability

- Bio-degradable

- Linear density range from 1330–2000 dtex (including plied constructions)/li>

- Available as twisted greige yarn or RFL-dipped yarn for excellent adhesion

Rayon:

- Excellent breaking tenacity with low elongation and low shrinkage for high dimensional stability

- Bio-degradable

- Linear density range from 1260–2440 dtex (including plied constructions)

- Available as twisted greige yarn or RFL-dipped yarn for excellent adhesion

Polyester (PET):

- Excellent breaking tenacity with medium elongation and low shrinkage

- High flexibility and handling

- Linear density range from 550–2200 dtex (including plied constructions)

- Available as twisted greige yarn or RFL-dipped yarn for excellent adhesion

Polyamide (PA66):

- Excellent breaking tenacity with medium to high elongation for extended flexibility

- Linear density range from 470–2100 dtex (including plied constructions)

- Available as twisted greige yarn or RFL-dipped yarn for excellent adhesion

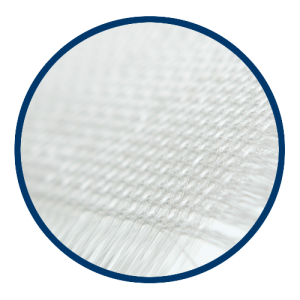

All RFL-dipped yarns have excellent properties of adhesion to commonly used rubber compounds, like EPDM, NR, SBR, and CR. Yarns can also be tailored to optimize adhesion to customer-specific rubber compounds.